Multi-Piston Pump

a multi-piston pump and pump body technology, applied in the direction of machines/engines, braking systems, positive displacement liquid engines, etc., can solve the problems of non-uniform mechanical forces on the bearing of the motor, high production effort and expense of such a multi-piston pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

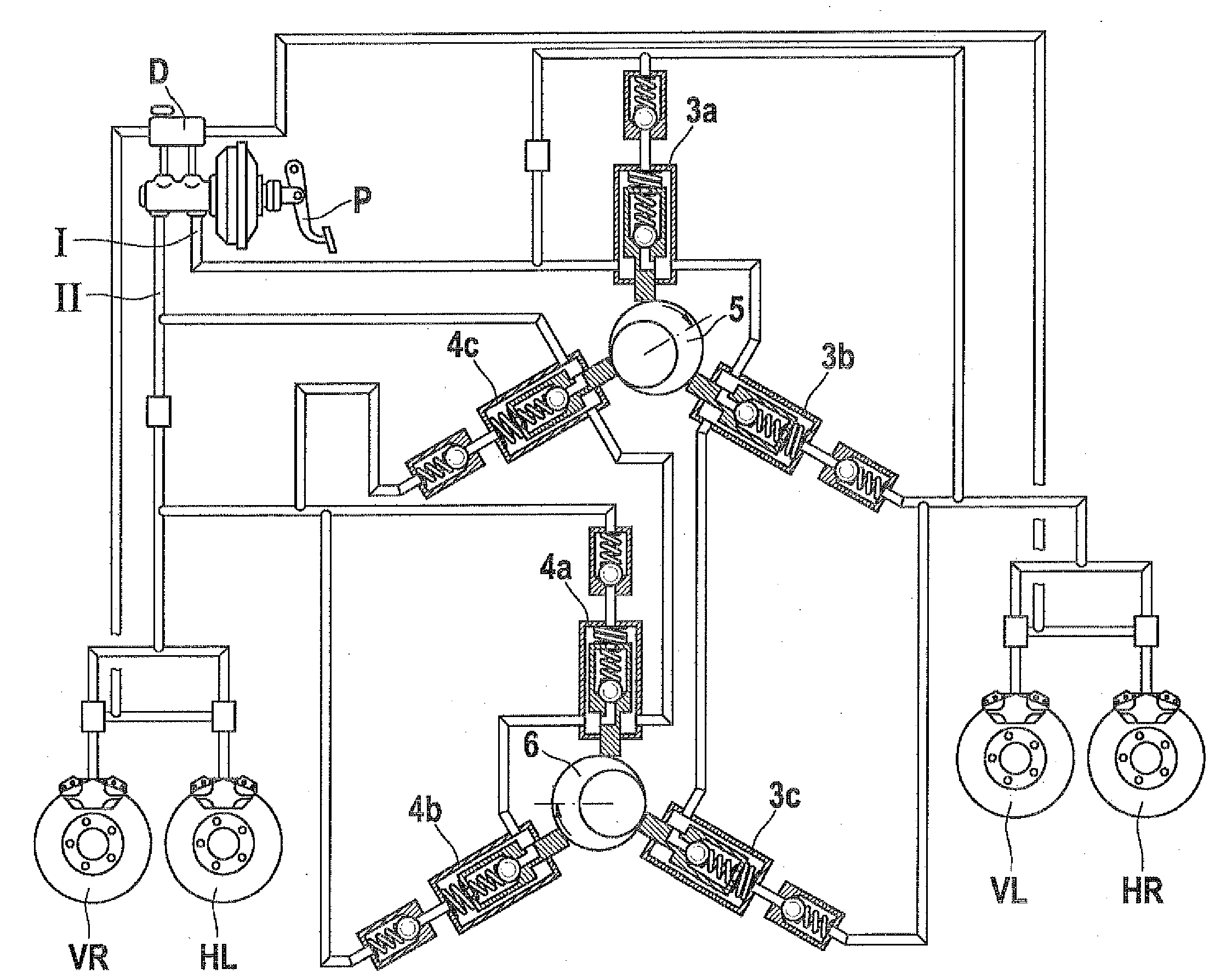

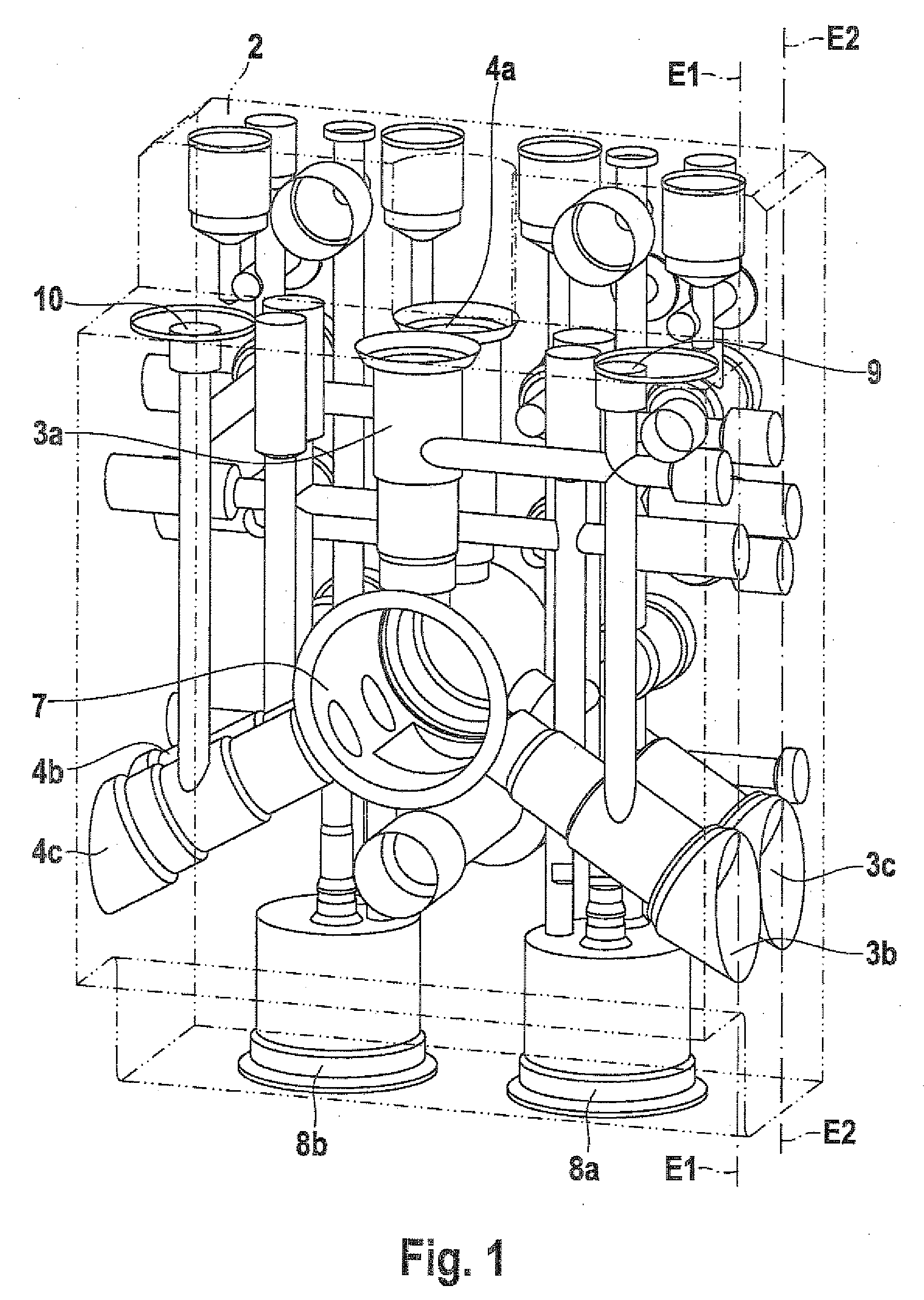

[0014]A multi-piston pump 1 in an exemplary embodiment of the invention will be described below, referring to FIGS. 1 through 3.

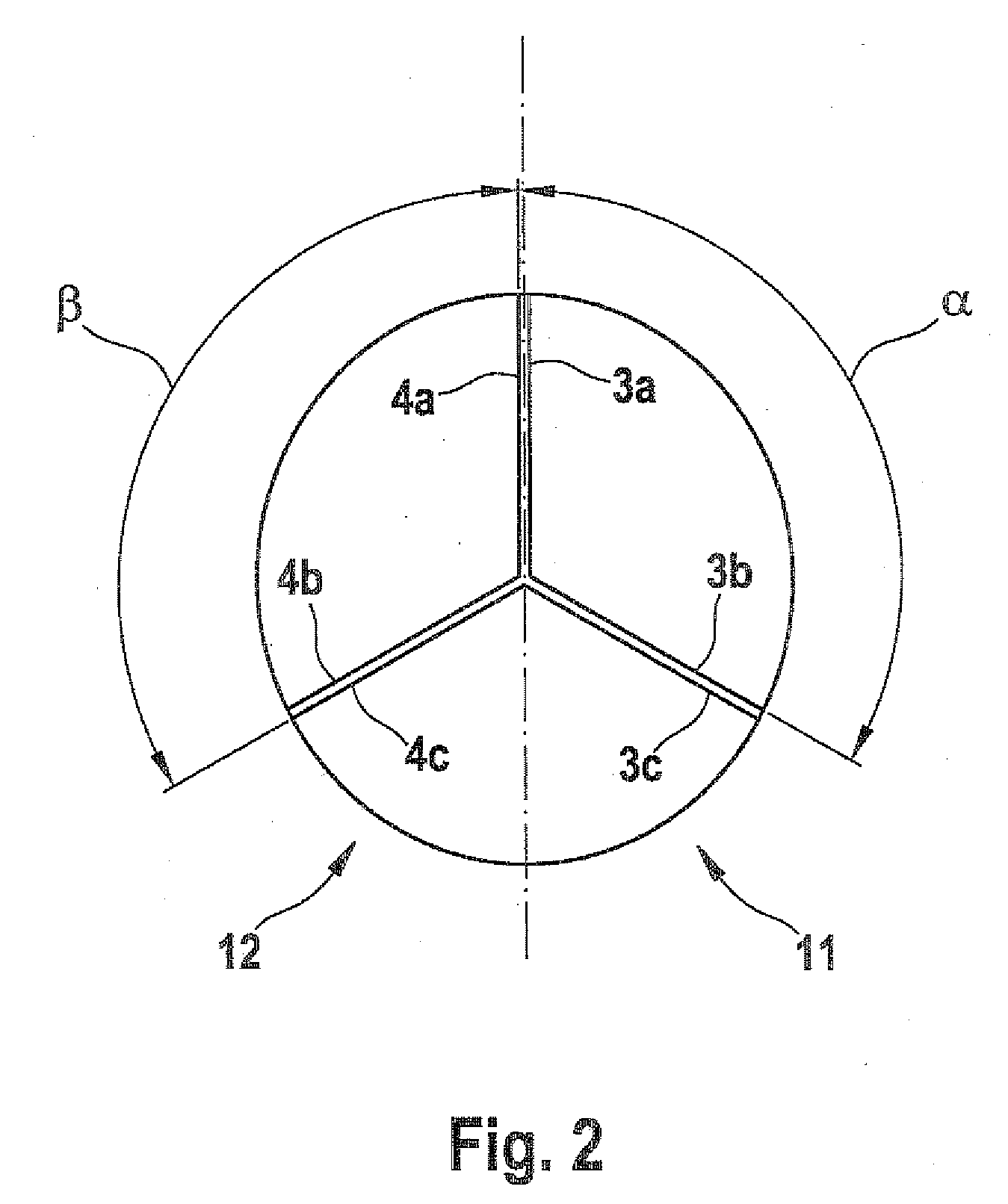

[0015]The multi-piston pump 1 includes a housing 2, a first pump unit 3, and a second pump unit 4. The first pump unit 3 includes three piston pumps 3a, 3b, 3c, and the second pump unit 4 includes three piston pumps 4a, 4b, 4c. As can be seen particularly in FIG. 3, three piston pumps each are disposed around a first eccentric 5 and around a second eccentric 6. Two piston pumps 3a, 3b of the first pump unit 3 and one piston pump 4c of the second pump unit 4 are associated with the first eccentric 5. One piston pump 3c of the first pump unit 3 and two piston pumps 4a, 4b of the second pump unit 4 are associated with the second eccentric 6. The piston pumps 3a, 3b, 3c of the first pump unit 3 finish the pressure in a first brake circuit I, and the piston pumps 4a, 4b, 4c of the second pump unit 4 furnish the pressure for a second brake circuit II. Also shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com