Plastic portable heat insulation cup

a portable heat insulation and plastic technology, applied in the field of plastic portable heat insulation cups, can solve the problems of deformation of paper drinking cups, coffee will easily leak therefrom, and hands become scalded, and achieve the effect of convenient us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

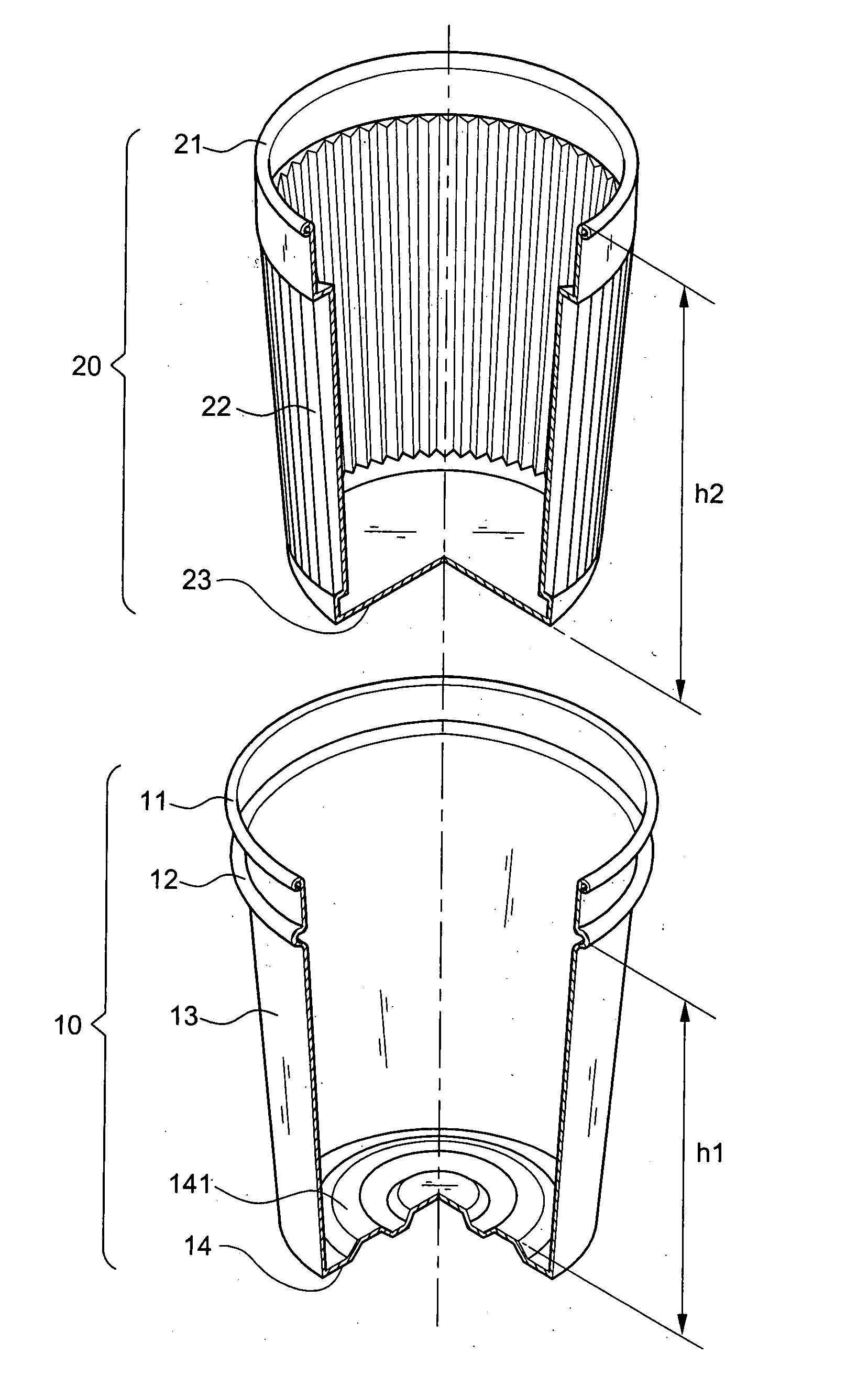

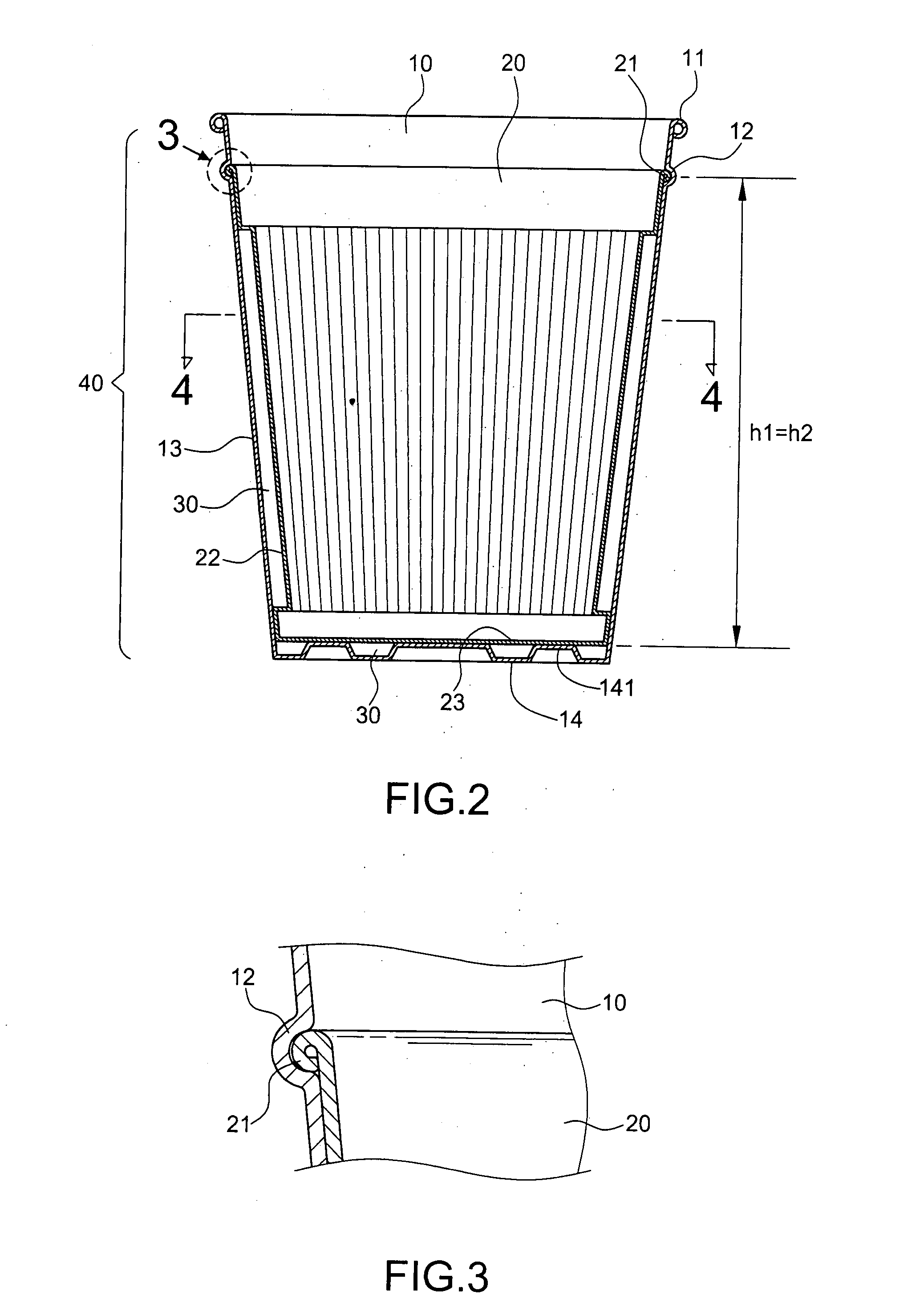

[0027]Referring to FIG. 1, a plastic portable heat insulation cup in accordance with a first preferred embodiment of the invention includes an external cup 10 and an internal cup 20. The external cup 10 and the internal cup 20 are made of plastic material like PE, PP, etc. by means of an injection molding process. A first lip rim 11 is formed by turning the rim portion of the external cup 10 inside out. An annular groove 12 with the external wall protruding outward is integrally formed at a place 3-13 mm lower than the first lip rim 11. The annular groove 12 is used to lock the internal cup 20 in place. As a result, it should be taken into account that the annular groove 12 should not be formed at a place where it is too near or too far away from the first lip rim 11. In case of the former one (the distance smaller than 3 mm), the first lip rim 11 will be easily deformed. In case of the latter one (the distance greater than 13 mm), the internal cup 20 with the effect of heat insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com