Fluid disinfection apparatus and method

a technology of disinfection apparatus and fluid, which is applied in the field of apparatus for disinfection fluid and to a method of disinfection fluid, can solve the problems of destroying the dna of any microorganism, killing or inactivating microorganisms, and being particularly difficult to achiev

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

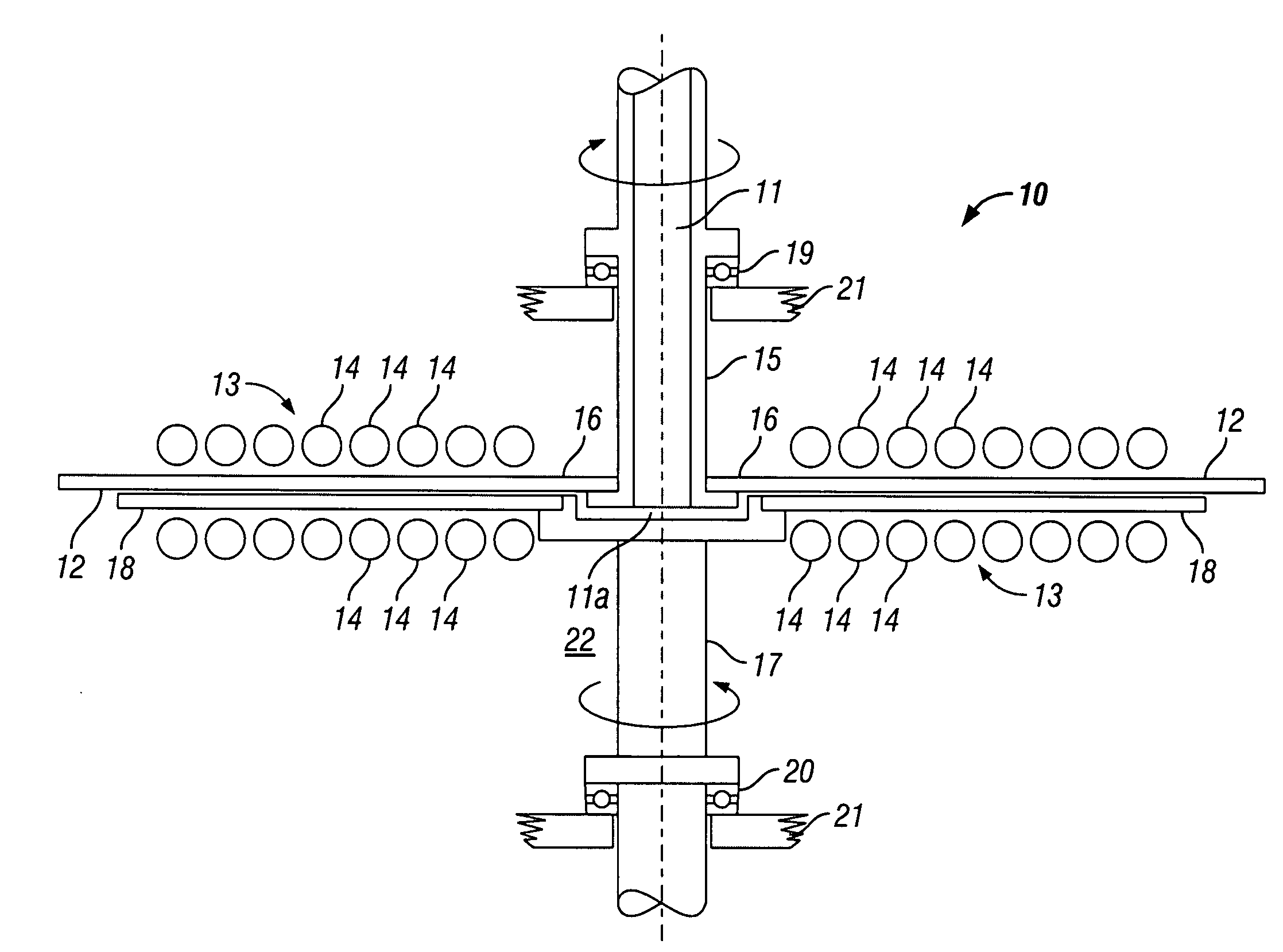

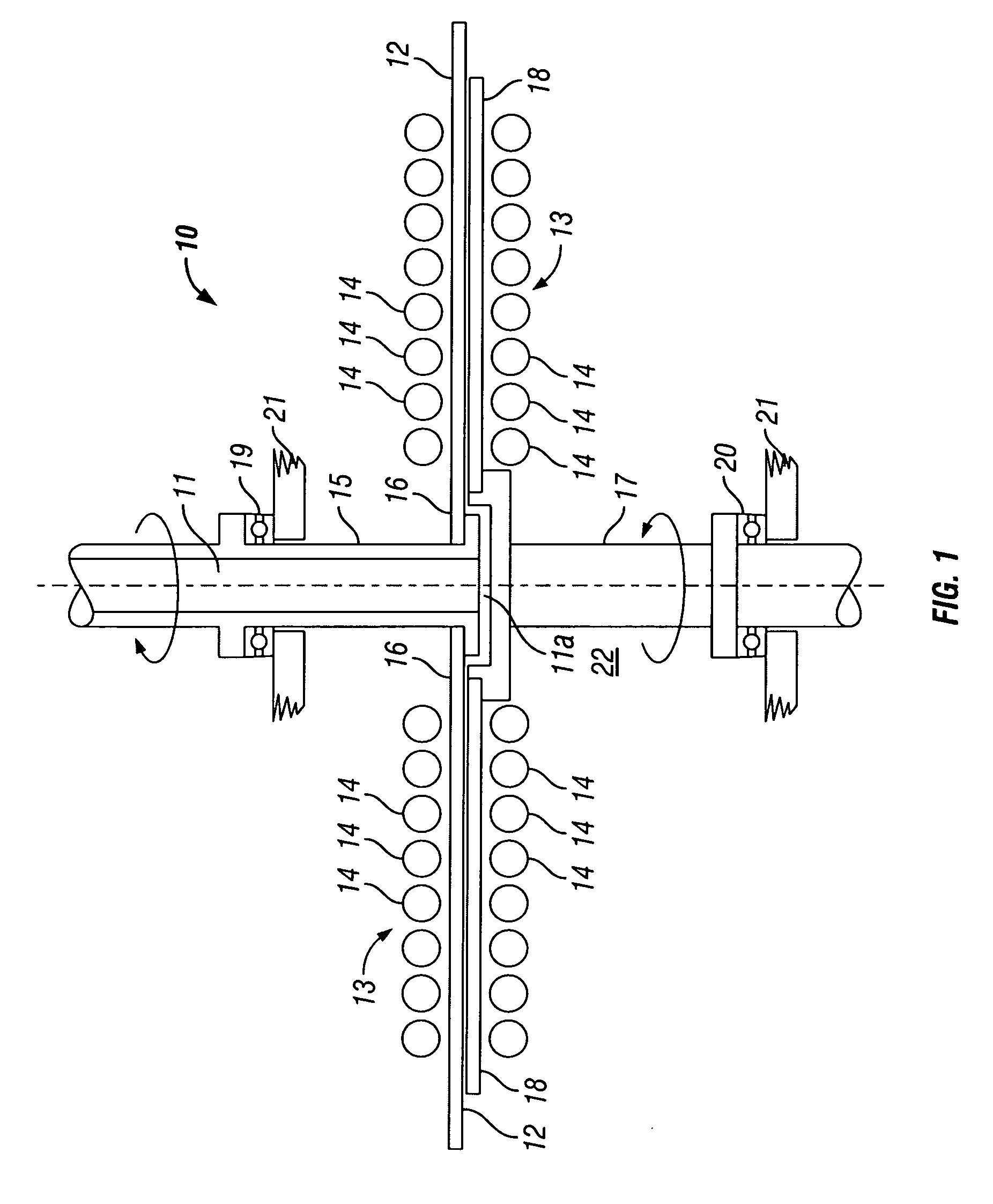

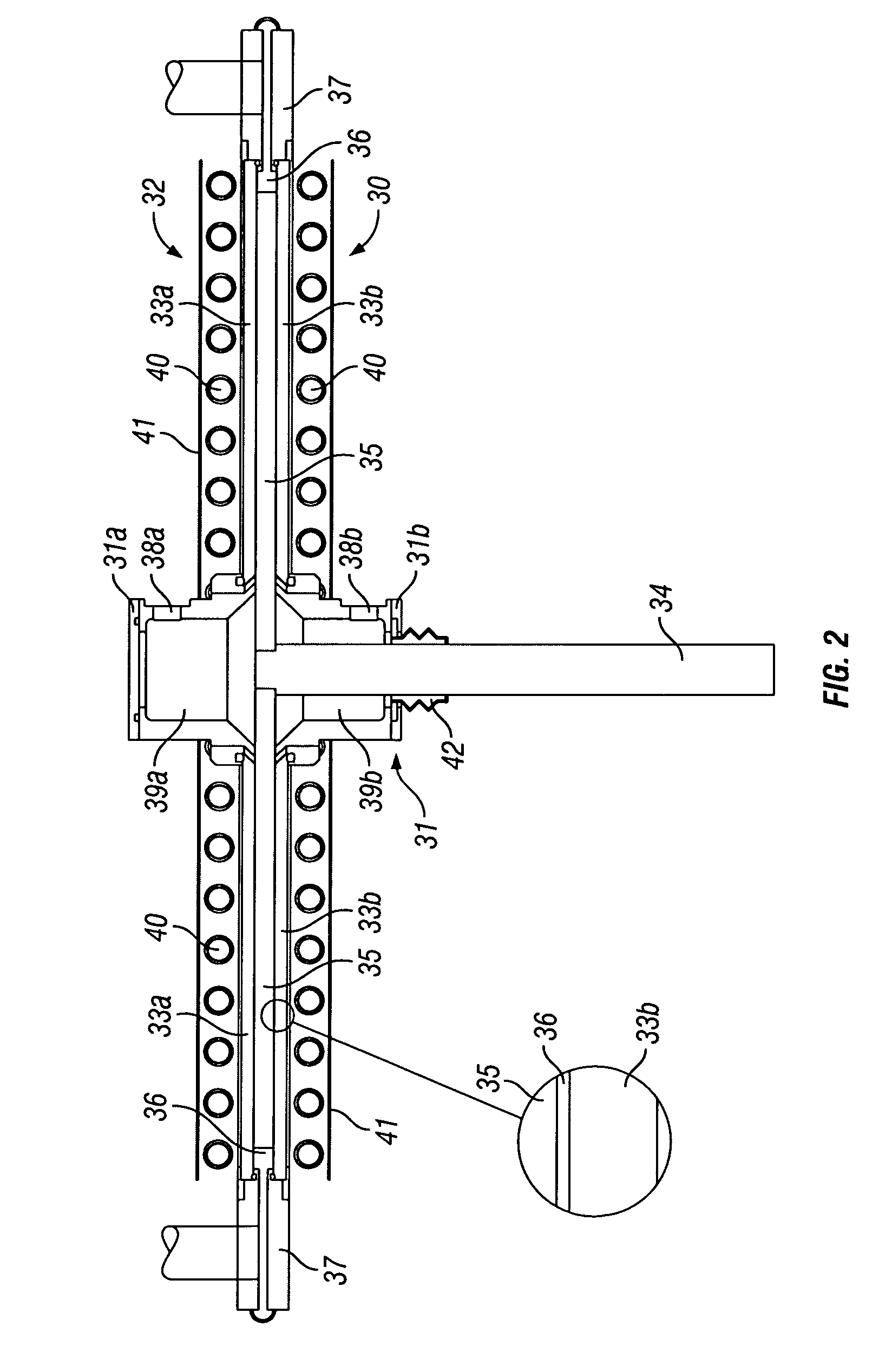

[0037]Referring to FIG. 1 of the drawings, there is shown a fluid disinfection apparatus 10 comprising a central duct 11 for receiving fluid to be disinfected into the apparatus from an inlet thereof. The inlet 11 is formed as a bore of a first drive shaft 15 and is in communication with a pressurised source of fluid to be disinfected. The fluid pressure is controlled by a pressure regulator (not shown); by controlling the pressure of the fluid, a controlled rate of fluid flow can be maintained through the apparatus.

[0038]The distal end of the first drive shaft is secured to the central portion of a first disc 16, with the bore 11 extending through the disc. Adjacent the first drive shaft 15 there is arranged a second drive shaft 17, the distal end of which is secured to the central portion of a second disc 18.

[0039]The first and second drive shafts 15,17 are arranged co-axially with each other. The drive shafts are mounted to bearing sleeves 19 and 20, which permit the drive shafts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative speeds | aaaaa | aaaaa |

| viscous | aaaaa | aaaaa |

| transmission coefficients | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com