Electrically-Driven Compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

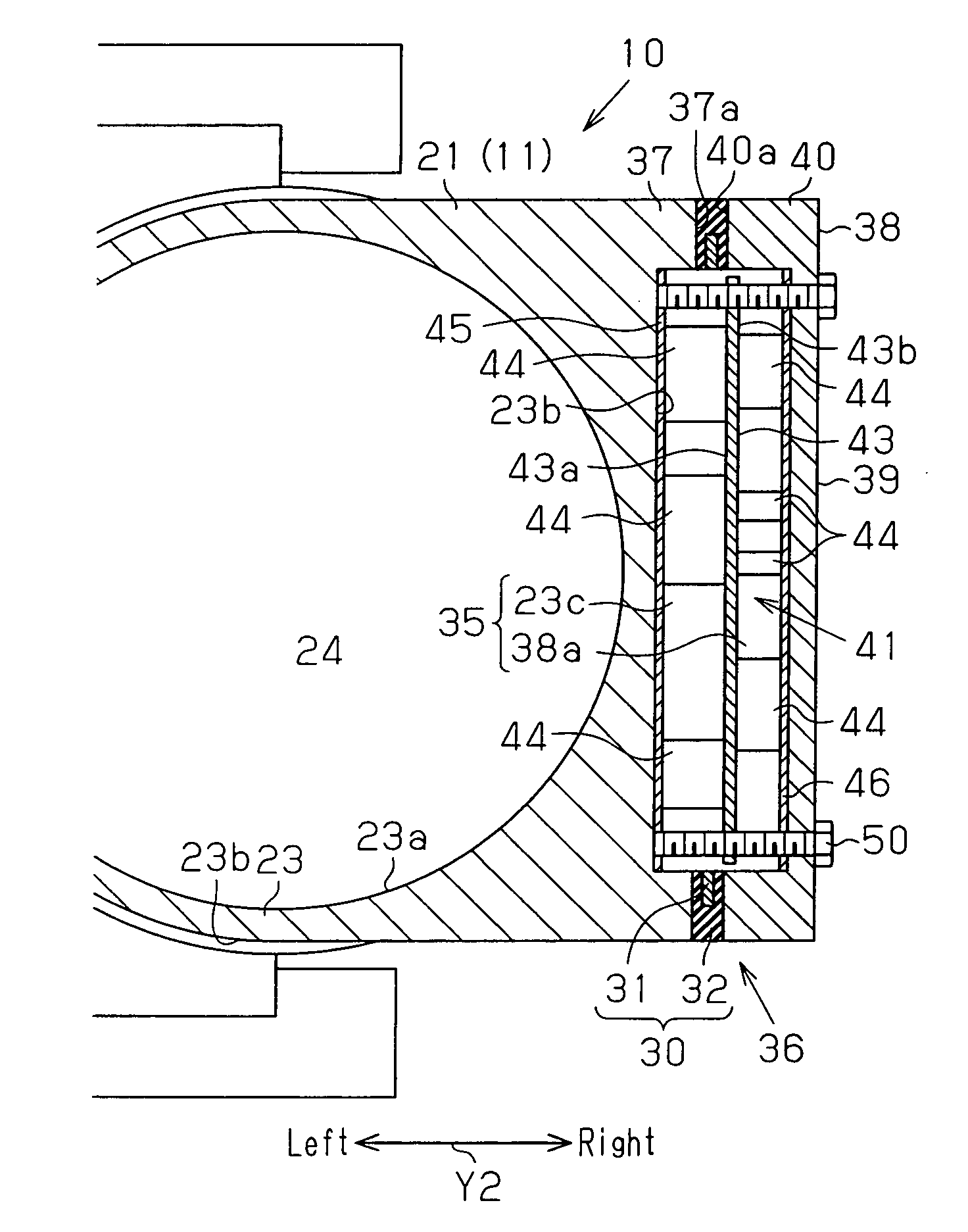

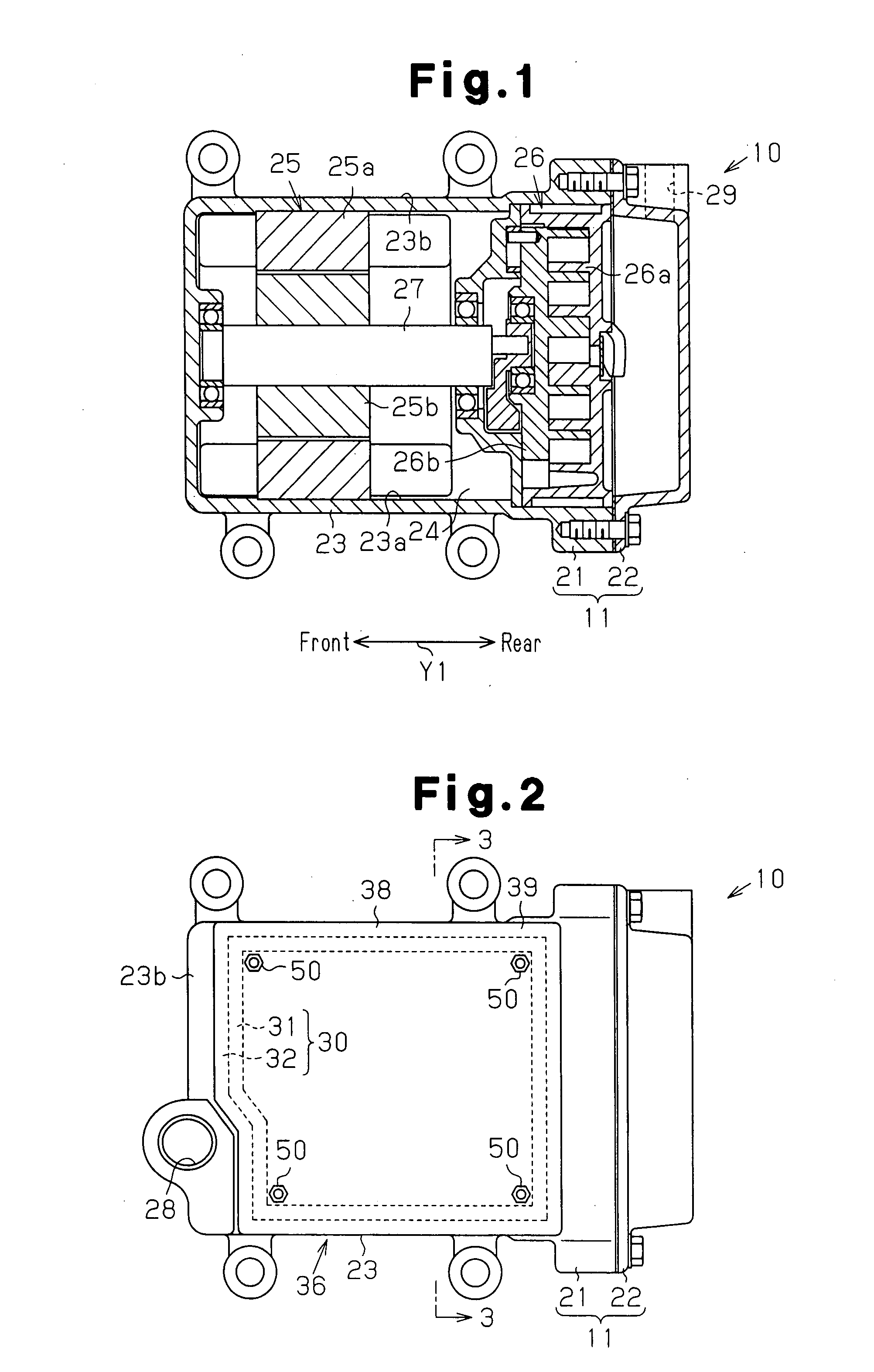

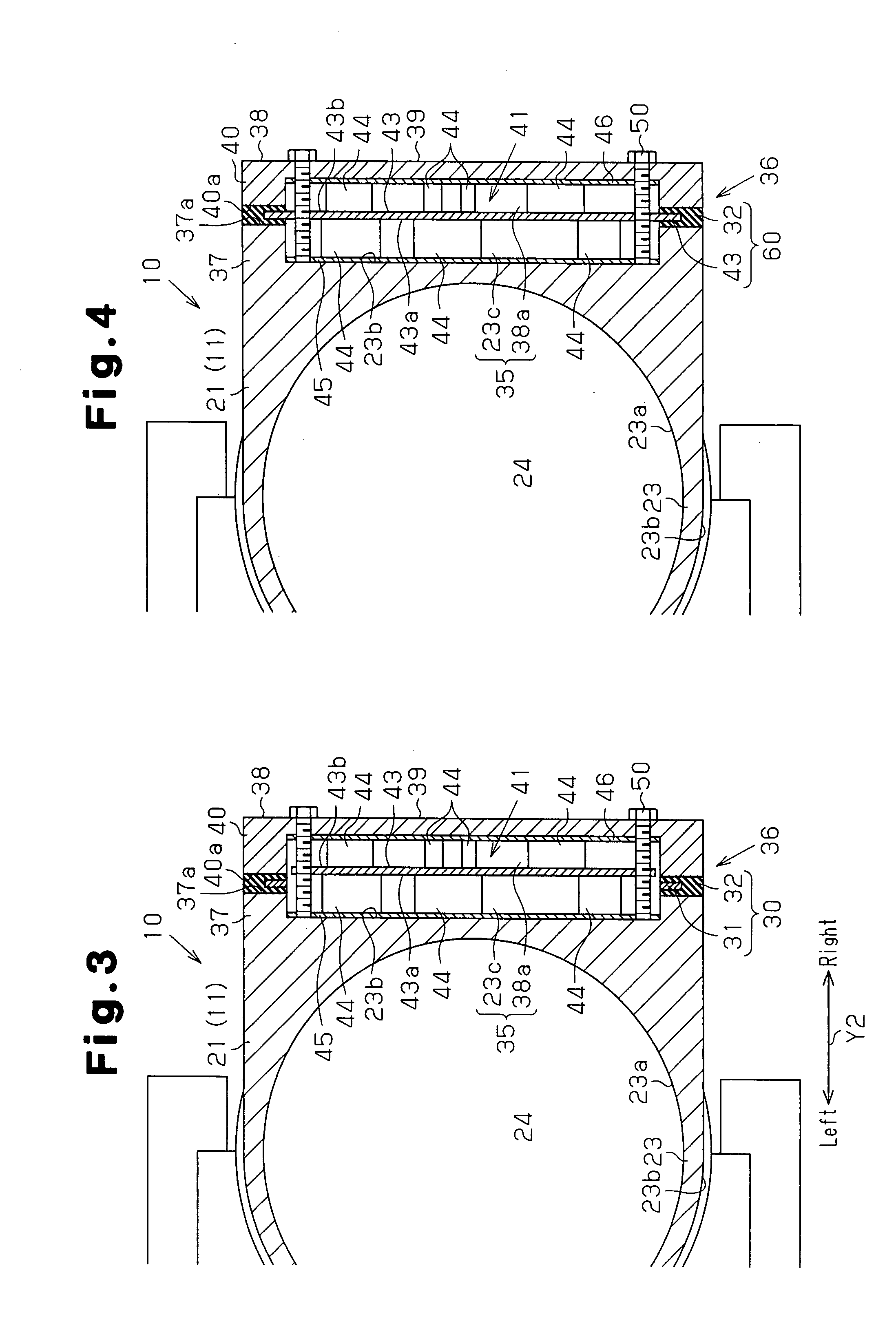

[0025]the present invention will now be described with reference to FIGS. 1 to 3. In the following description, the “front” and “rear” of the compressor correspond to the directions of the arrow Y1 shown in FIG. 1, and the “left” and “right” correspond to the directions of the arrow Y2 shown in FIG. 3.

[0026]As shown in FIG. 1, a housing 11 forming the outer shell of an electrically-driven compressor 10 includes a first housing element 21 and a second housing element 22. The second housing element 22 is joined and fixed to the rear end of the first housing element 21. The first housing element 21, which is formed by die casting aluminum alloy, has a bottom located at the front end of a substantially cylindrical circumferential wall 23. The second housing element 22, which is formed by die casting aluminum alloy, is cylindrical and has a lid located at the rear end. A sealed space 24 is formed between the first housing element 21 and the second housing element 22.

[0027]The first housi...

second embodiment

[0048]As shown in FIG. 4, a sealing member 60 of the second embodiment is formed with the seal portion 32 integrated with a circumferential edge part of a circuit board 43, which has the shape of a four-side plate, in the motor drive circuit 41. That is, the circumferential edge part of the circuit board 43 is also used as the shape sustaining member for sustaining the seal portion 32 in the shape conforming to the open ends 37a and 40a.

[0049]Accordingly, the present embodiment has the following advantage in addition to the advantages similar to advantages (1) to (5) of the first embodiment.

[0050](8) The sealing member 60 is formed by integrating the seal portion 32 with the circuit board 43 of the motor drive circuit 41. Thus, the seal portion 32 may be arranged at the circumferential edge of the accommodation space 35 at the same time when arranging the motor drive circuit 41 in the accommodation space 35. Thus, in the present embodiment, the task for forming the accommodation po...

third embodiment

[0052]As shown in FIG. 5, the accommodation portion 36 is arranged on the upper part of the circumferential wall 23 of the first housing element 21 in the That is, the accommodation portion 36 includes the side wall 37 of four-sided frame shape integrally extended from the outer surface 23b (upper surface in FIG. 5) of the circumferential wall 23, and a cover member 38 attached and fixed to the side wall 37. The sealing member 30 is arranged between the open end 37a of the side wall 37 in the housing 11 and the open end 40a of the circumferential wall portion 40.

[0053]As shown in FIG. 6, the sealing member 30 is formed to have a four-sided frame shape and arranged along the circumferential edge of the accommodation space 35. The sealing member 30 includes the core 31, which serves as a shape sustaining member having the shape of a generally four-sided frame, and a seal portion 32, which is made of a rubber material integrated with the core 31. The sealing member 30 has an outline f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com