Waterproof safety footwear

a technology for safety footwear and waterproof shoes, applied in the direction of bootlegs, uppers, apparel, etc., can solve the problems of labor-intensive plate salvage, molds are also expensive to produce, and expensive fabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

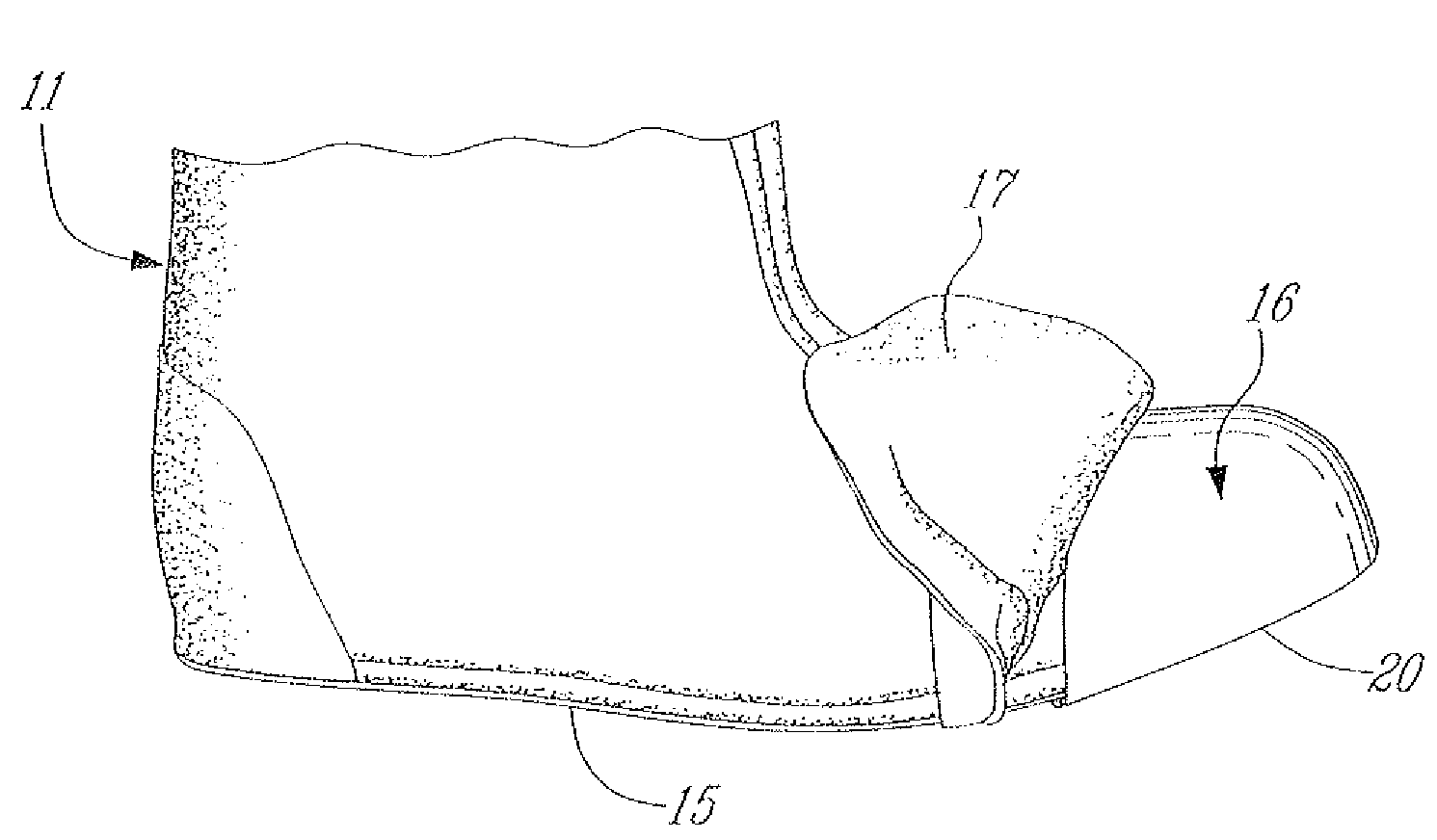

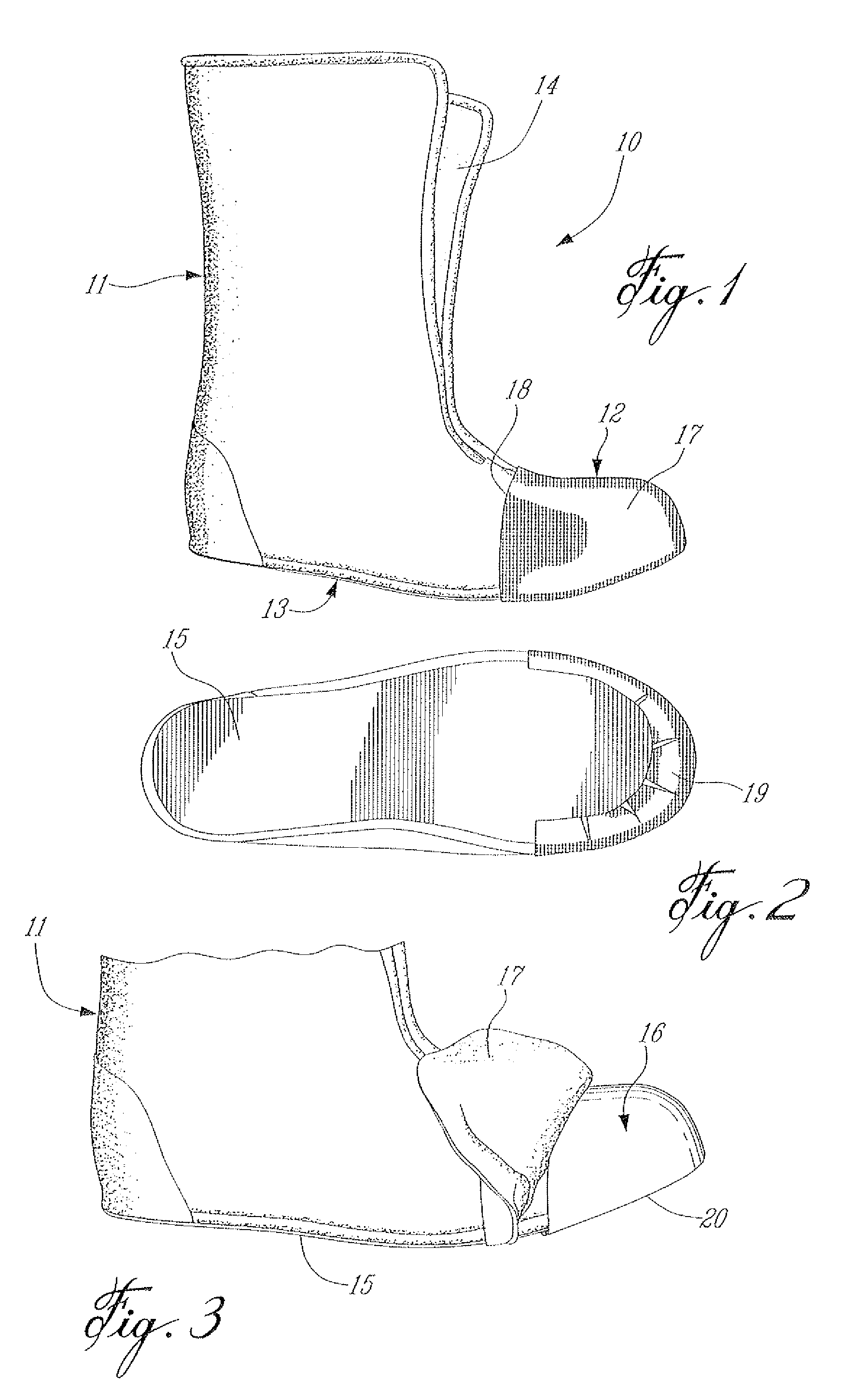

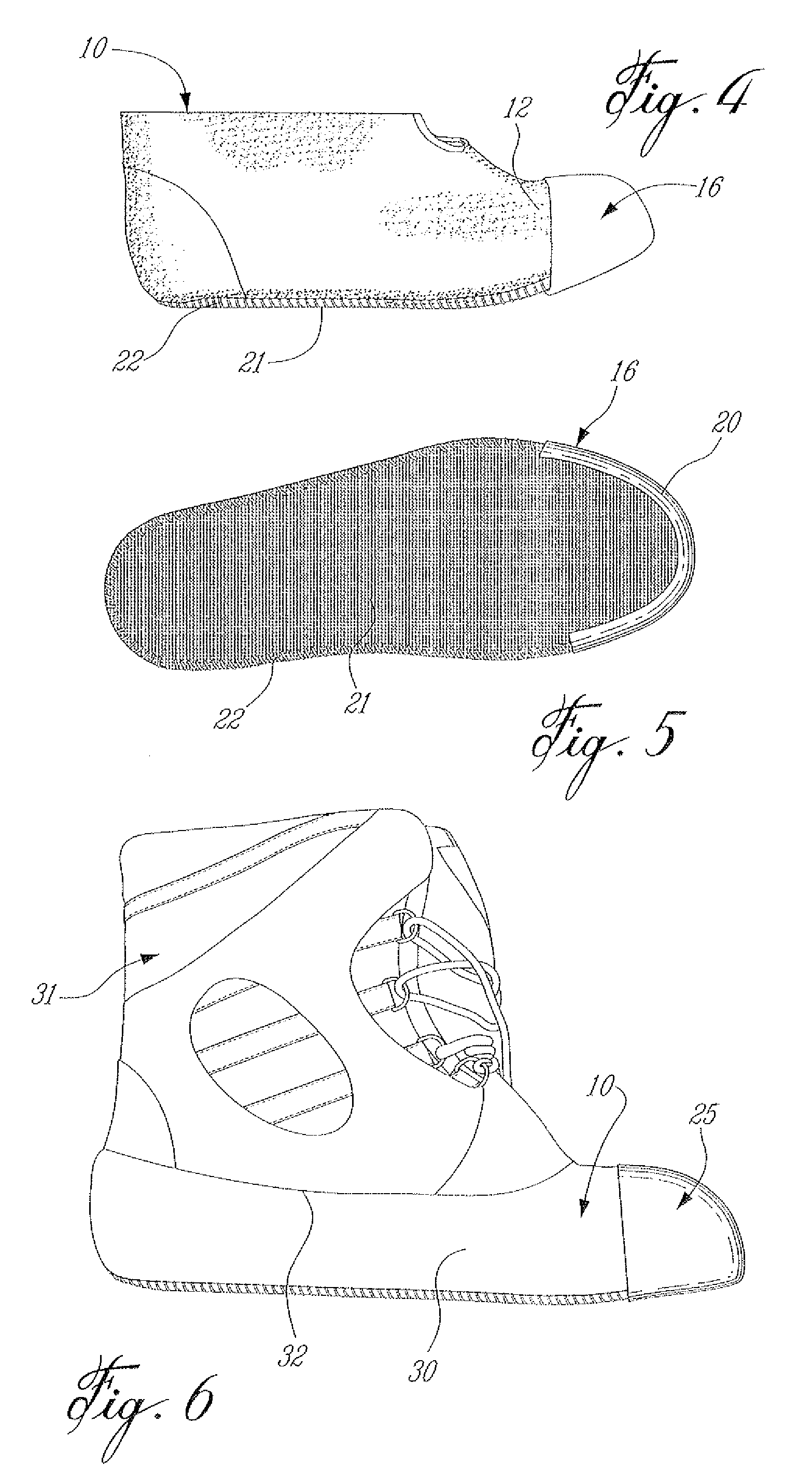

[0023]Referring now to the drawings and more particularly to FIGS. 1 to 3, there is shown generally at 10 an inner protective boot liner constructed in accordance with the present invention. The boot liner 10 as herein illustrated is comprised of a boot upper 11 formed from felt material although foam or other textile fabric materials may be used and it has a toe portion 12 and a sole portion 13. The front portion of the boot upper 11 is an open portion 14 to facilitate insertion and removal of the boot liner 10 from an outer boot shell such as the boot shell 50 illustrated in FIG. 9. Accordingly, the protective liner 10 is removably retained inside an outer boot shell.

[0024]As herein illustrated with more specific reference to FIG. 2, the boot liner has a puncture proof thin steel plate 15 secured to the sole portion 13 thereof such as by gluing it thereto. As shown in FIG. 3, a steel toe cap 16 is also secured over the toe portion 12 of the boot liner 10 and this is herein accompl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| thermoplastic | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com