Grating with a plate detachably mounted in a frame for covering a drainage channel

a technology of drainage channel and plate, which is applied in the field of covering, can solve the problems of inability to interchange different “designs”, high construction cost in the case of larger model range, and inability to meet the requirements of construction, and achieve the effect of simplifying assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]In the following description the same reference symbols are used for parts which are the same or have the same functions.

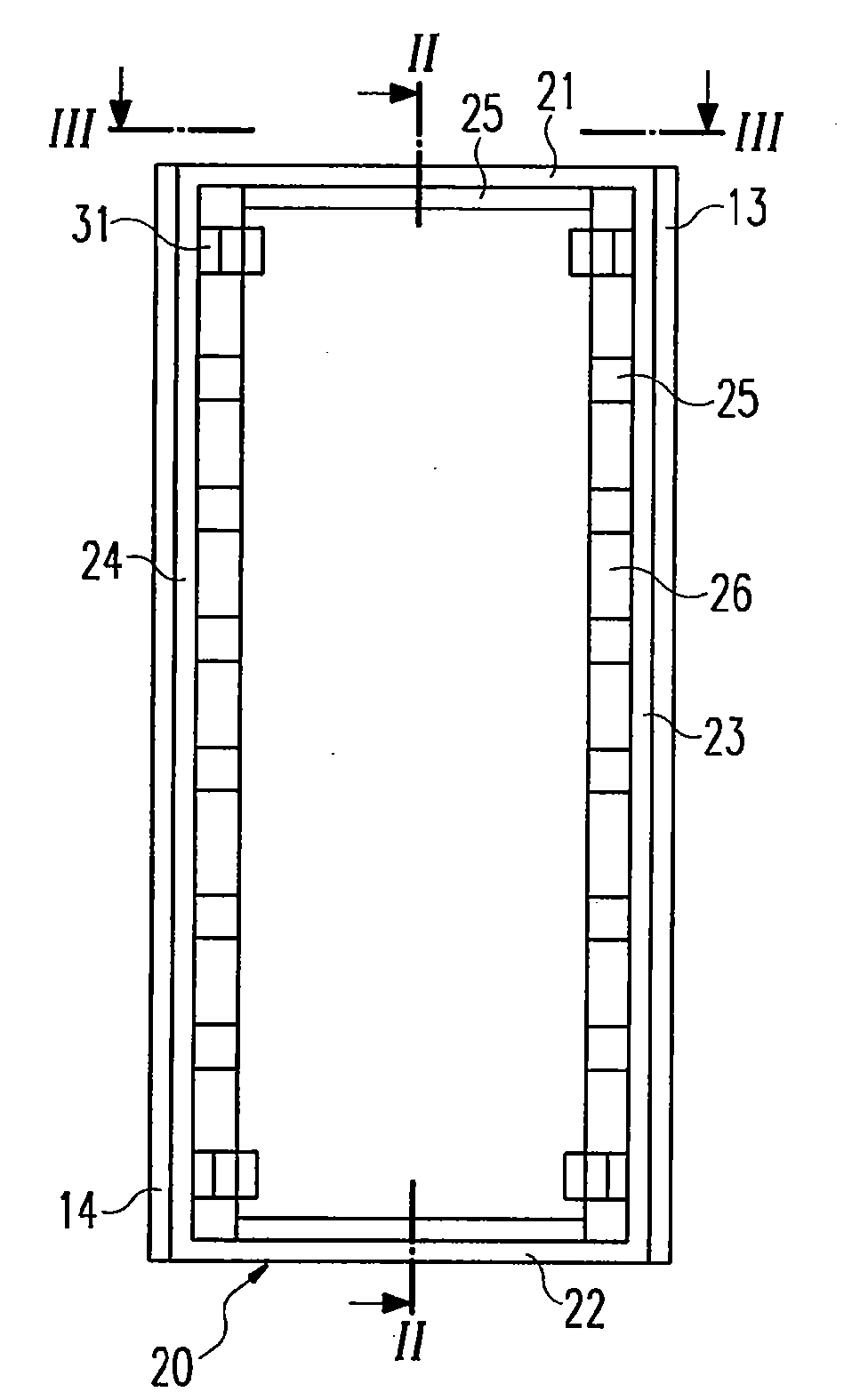

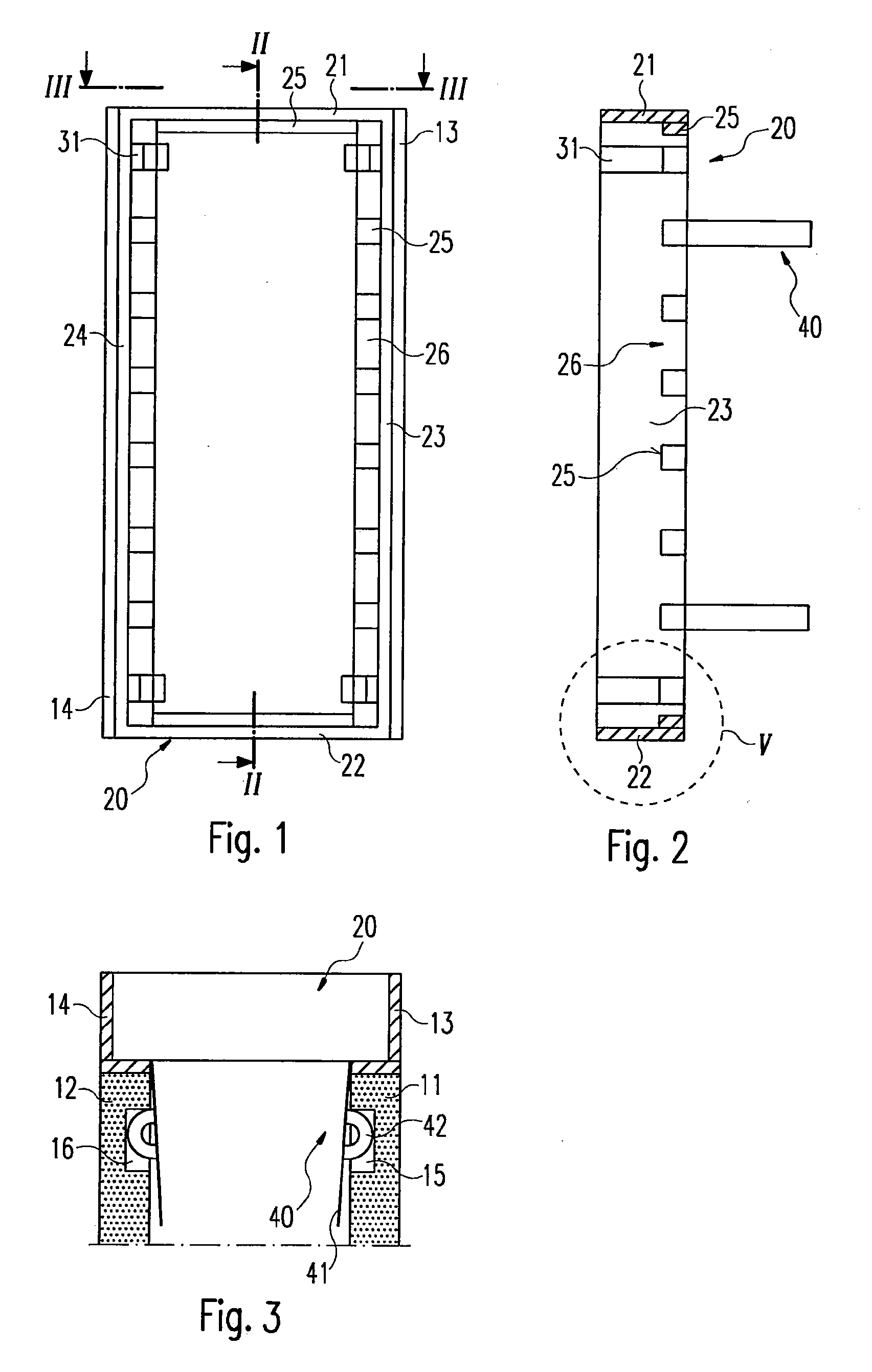

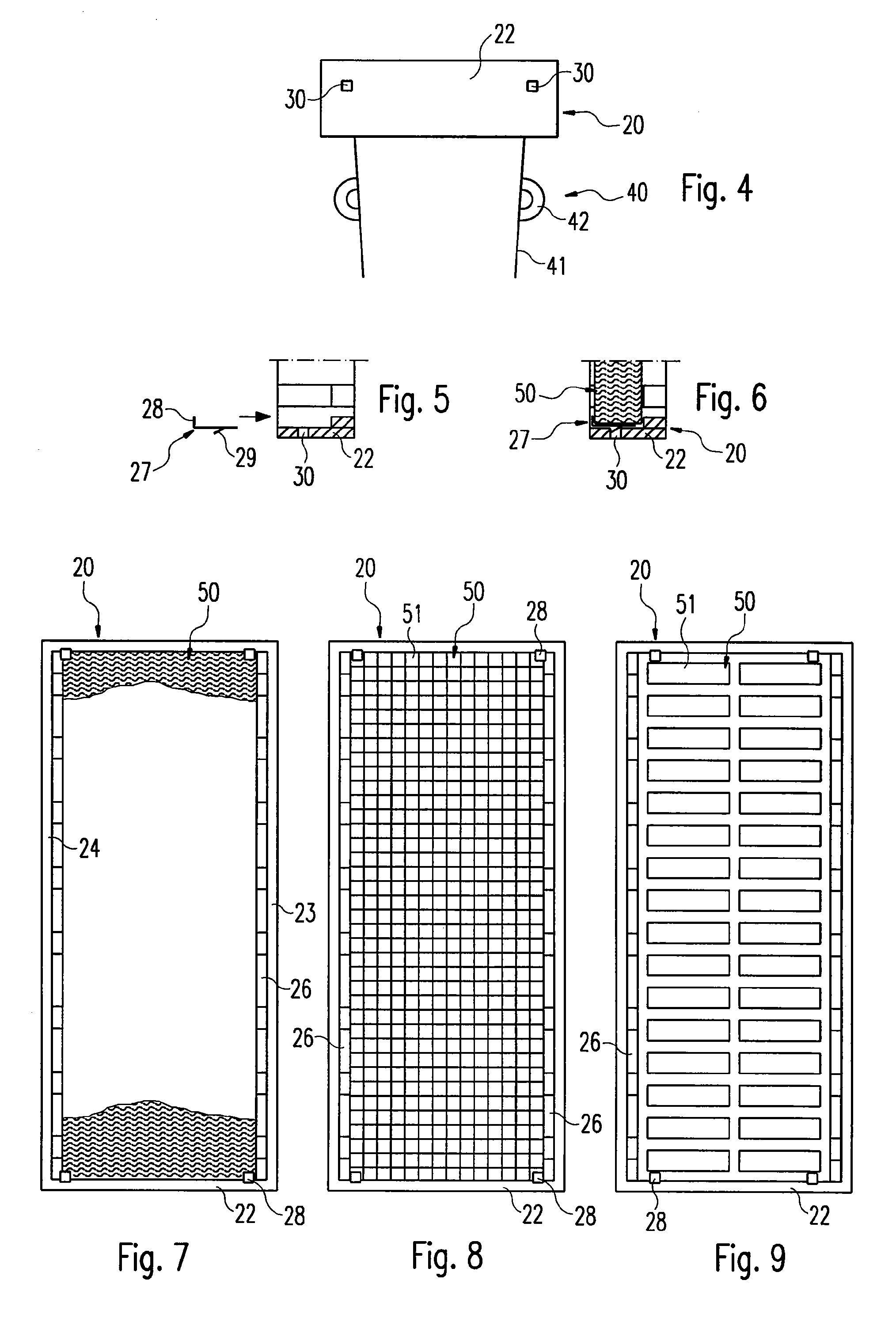

[0026]As shown in FIGS. 1-3, seated over the upper edges of side walls 11 and 12 is a channel 10 and casing 13, 14. In conventional drainage channels, a grating is located aid inside the casing. In the case of the embodiment of the invention shown here, a frame 20 is provided that has a front wall 21, a rear wall 22 and side walls 23, 24, which are solidly joined with one another. Supports 25 are provided, projecting from the walls 21-24 of the frame 20 towards the frame inner space, between which supports are outlet apertures 26.

[0027]Furthermore, fixing pieces 40 are attached to the side walls 23, 24 of the frame 20, which exhibit spring strips 41 and stop lugs 42 projecting outwards.

[0028]If the frame 20—as shown in FIG. 3—is inserted in a channel 10 between its walls 13, 14 respectively, the fixing pieces 40 protrude into the channel with their spring st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com