System and method for cooling the barrel of a firearm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

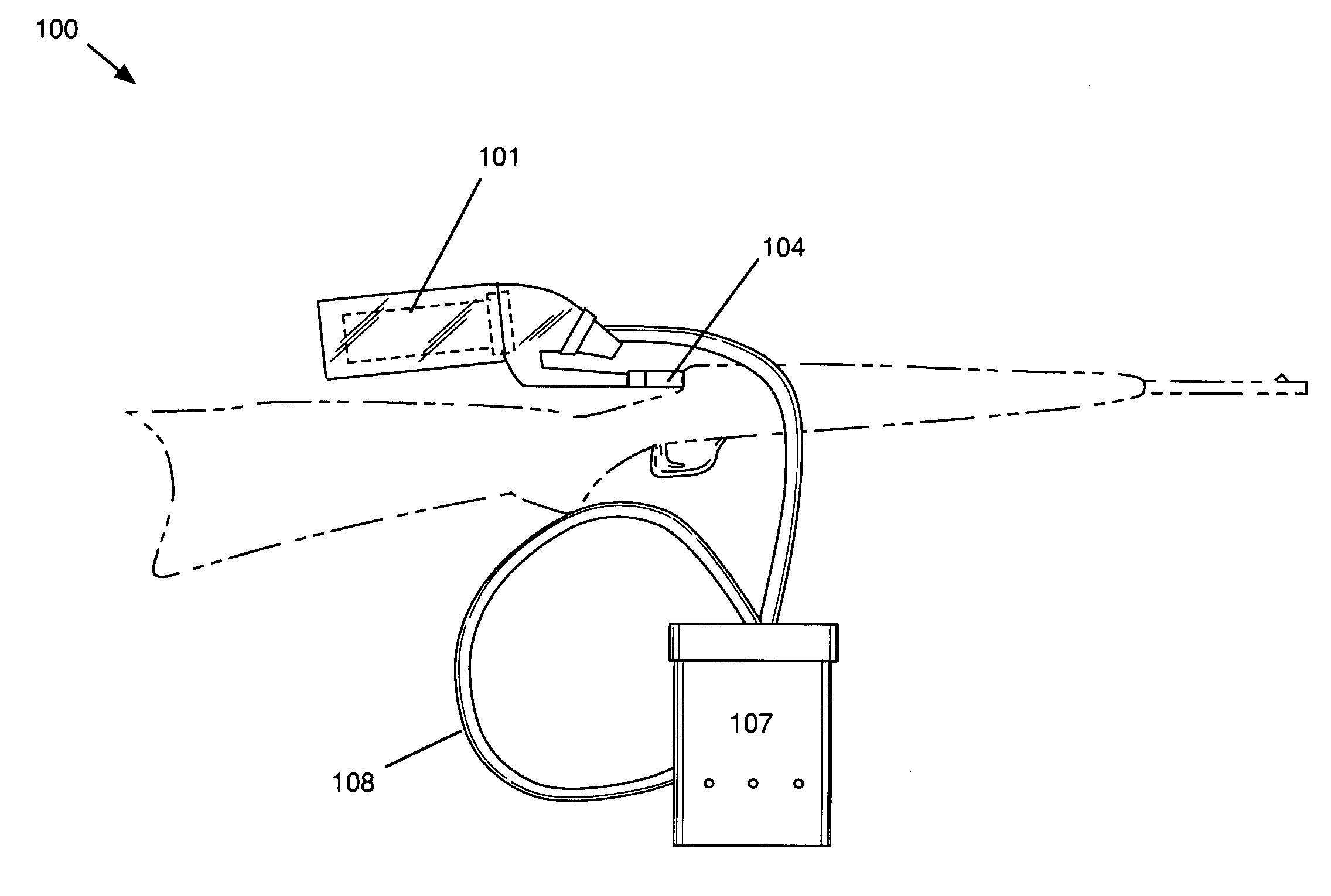

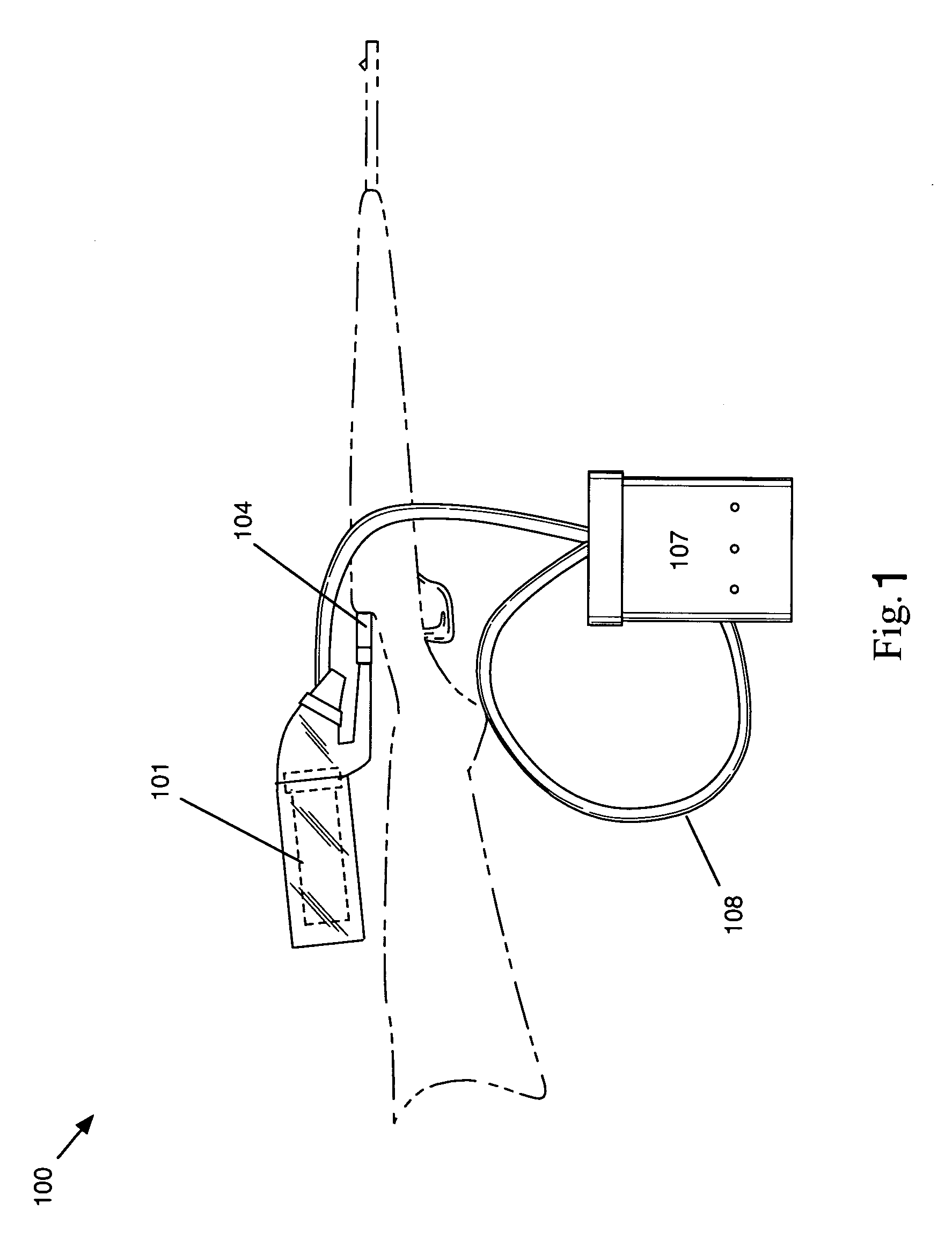

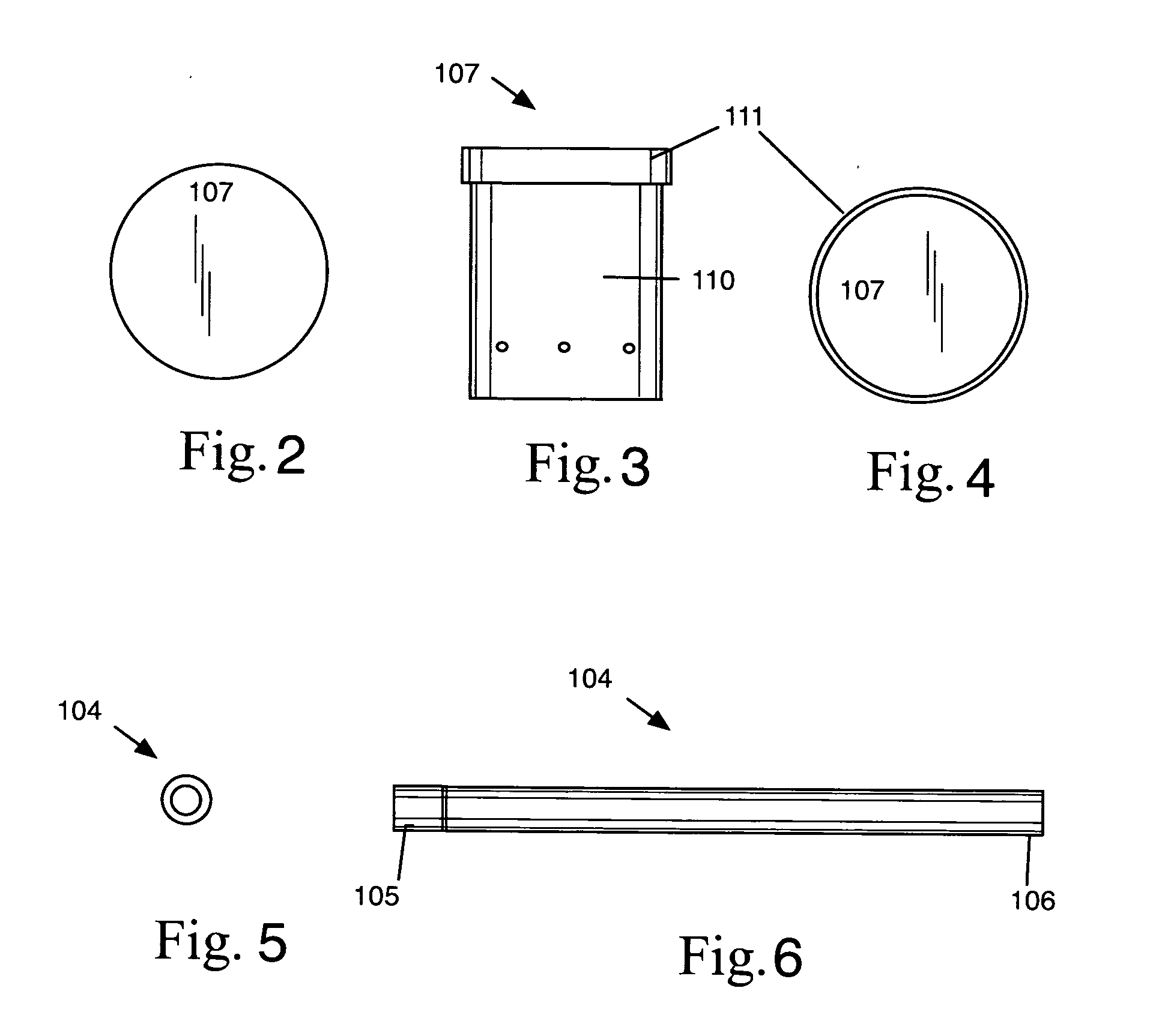

[0029]According to a preferred embodiment of the present invention, a unique system, method, and apparatus are used to cool the barrel of a rifle. The present invention is described in enabling detail below.

[0030]For the purposes of the present invention the term “cold-shot” shall refer to the first shot a shooter takes whether in a practice session, a competitive event, or in the field. The temperature of the barrel of a rifle just before a cold shot is taken, at that moment in time, provides the baseline for which consistency is predicated. By recording this temperature, one will have a good idea as to the relative thermal distortion or lack thereof of the firearm after firing a given number of shots.

[0031]For the purposes of the present invention the term “firearm” shall include rifles, guns, shotguns, pistols, “sharp-shooting” rifles, etc. Although the present invention is primarily aimed at problems which are mainly associated with rifles, it is conceivable that the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com