Exhaust Gas Purification Device For Internal Combustion Engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

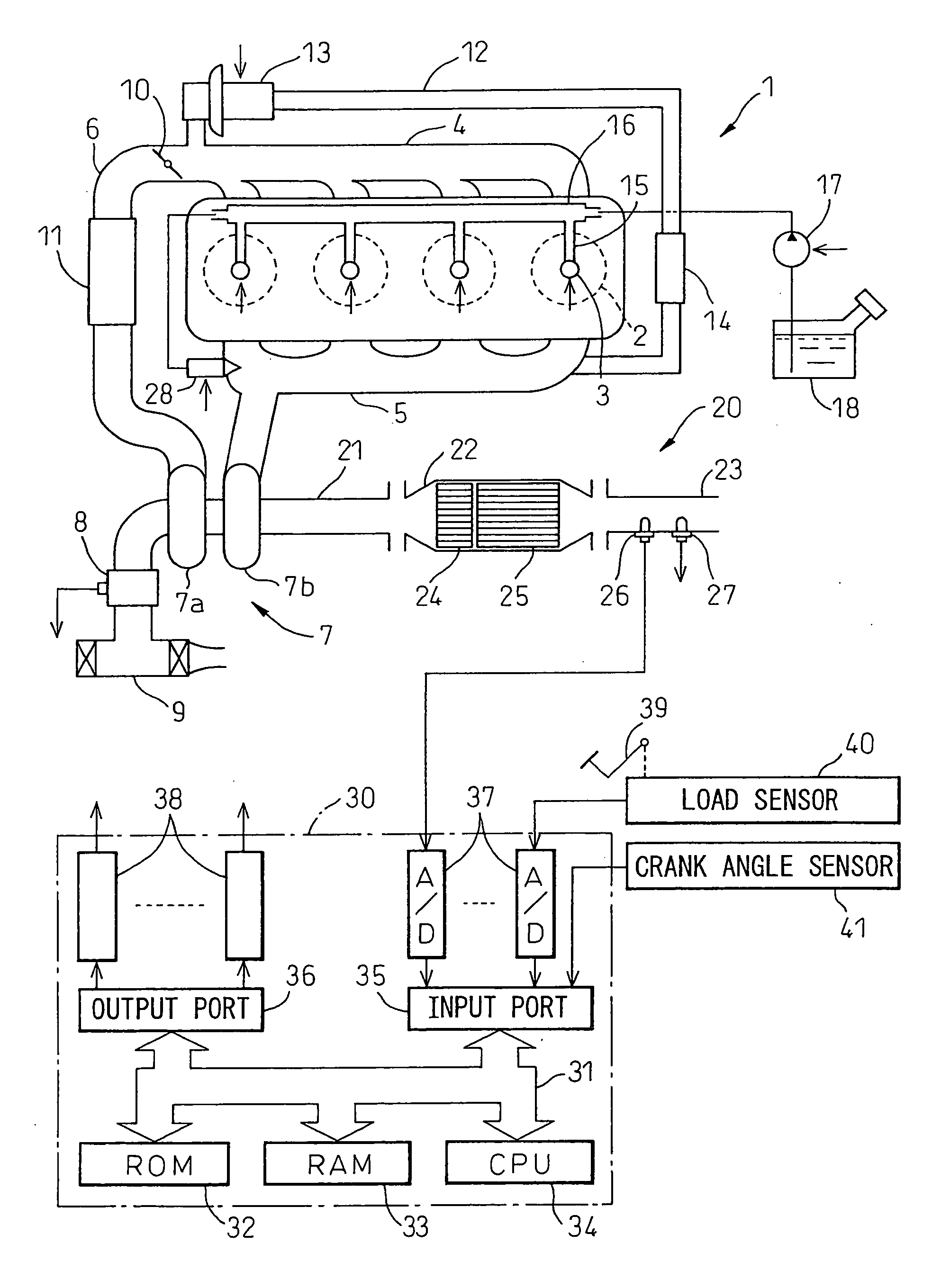

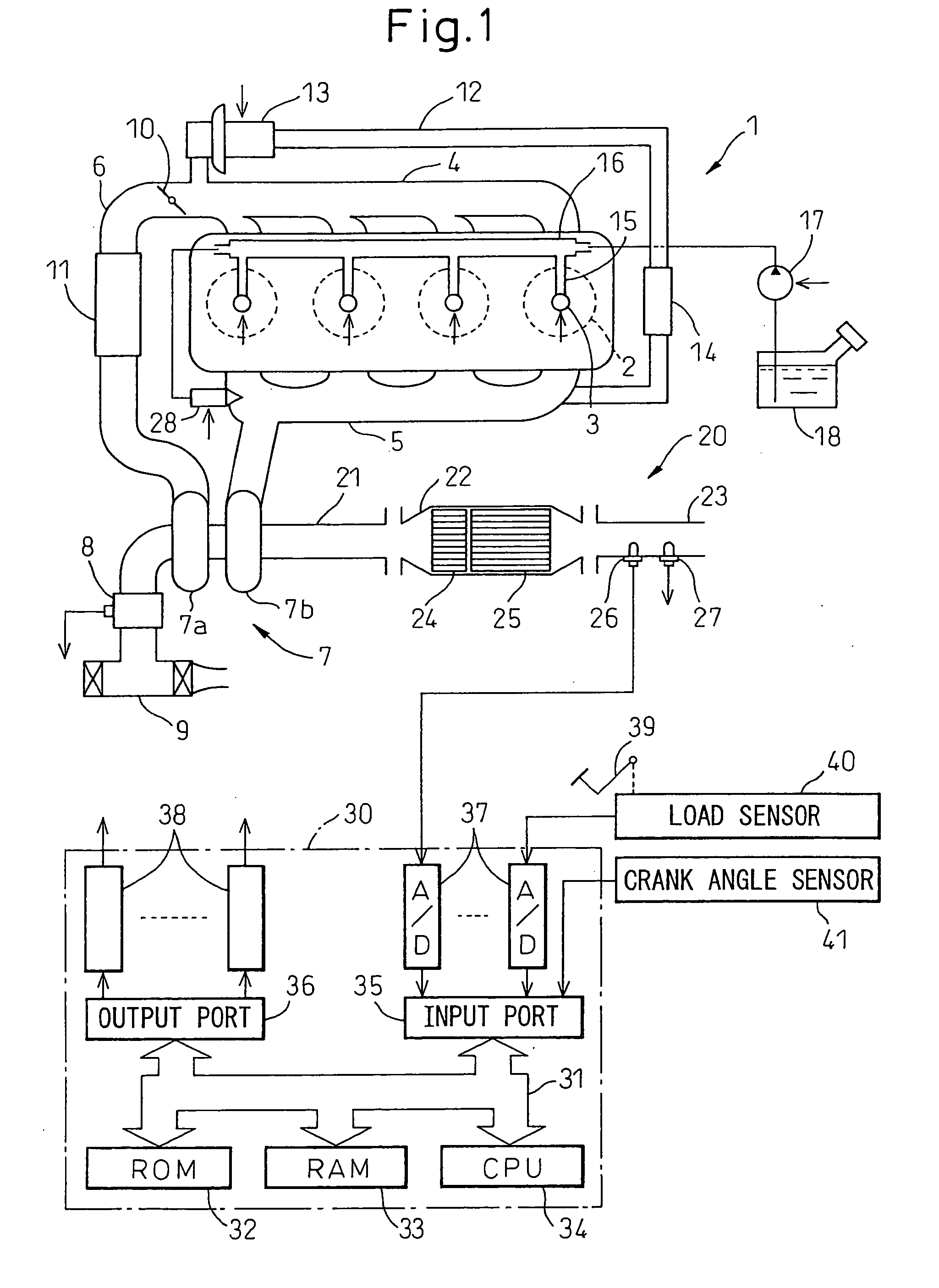

[0016]FIG. 1 illustrates a case where the present invention is applied to an internal combustion engine with a compression type ignition. Alternatively, the present invention may also be applied to an internal combustion engine with a spark type ignition.

[0017]Referring to FIG. 1, numeral 1 indicates an engine body, 2 a combustion chamber of each cylinder, 3 an electrically-controlled fuel injector for injecting fuel into each combustion chamber 2, 4 an intake manifold, and 5 an exhaust manifold. The intake manifold 4 is connected through an intake duct 6 to an outlet of a compressor 7a of a turbocharger 7. The inlet of the compressor 7a is connected via an air flow meter 8 to an air cleaner 9. An electrically-controlled throttle valve 10 is arranged in the intake duct 6. Further, a cooling device 11 is arranged around the intake duct 6 for cooling intake air flowing through the intake duct 6. In the embodiment shown in FIG. 1, engine cooling water is guided into the cooling device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com