Molten metal reactor utilizing molten metal flow for feed material and reaction product entrapment

a technology of molten metal and reaction product, which is applied in the direction of liquid-gas reaction process, chemical/physical/physico-chemical process, chemical apparatus and processes, etc., can solve the problems of not being well suited to submerging other types of materials, and the plunger structure is not well suited for use in relatively high-volume waste treatment applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

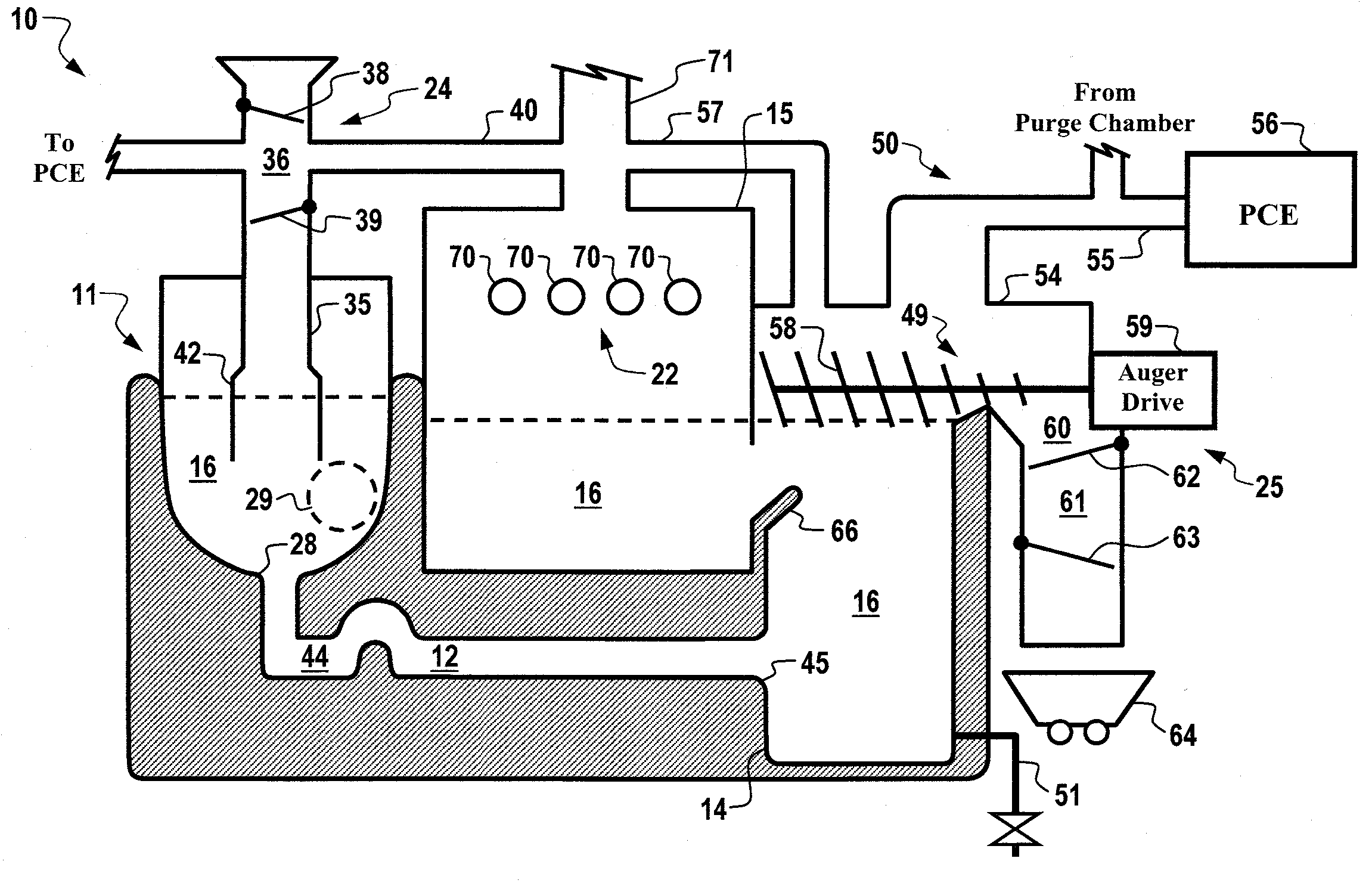

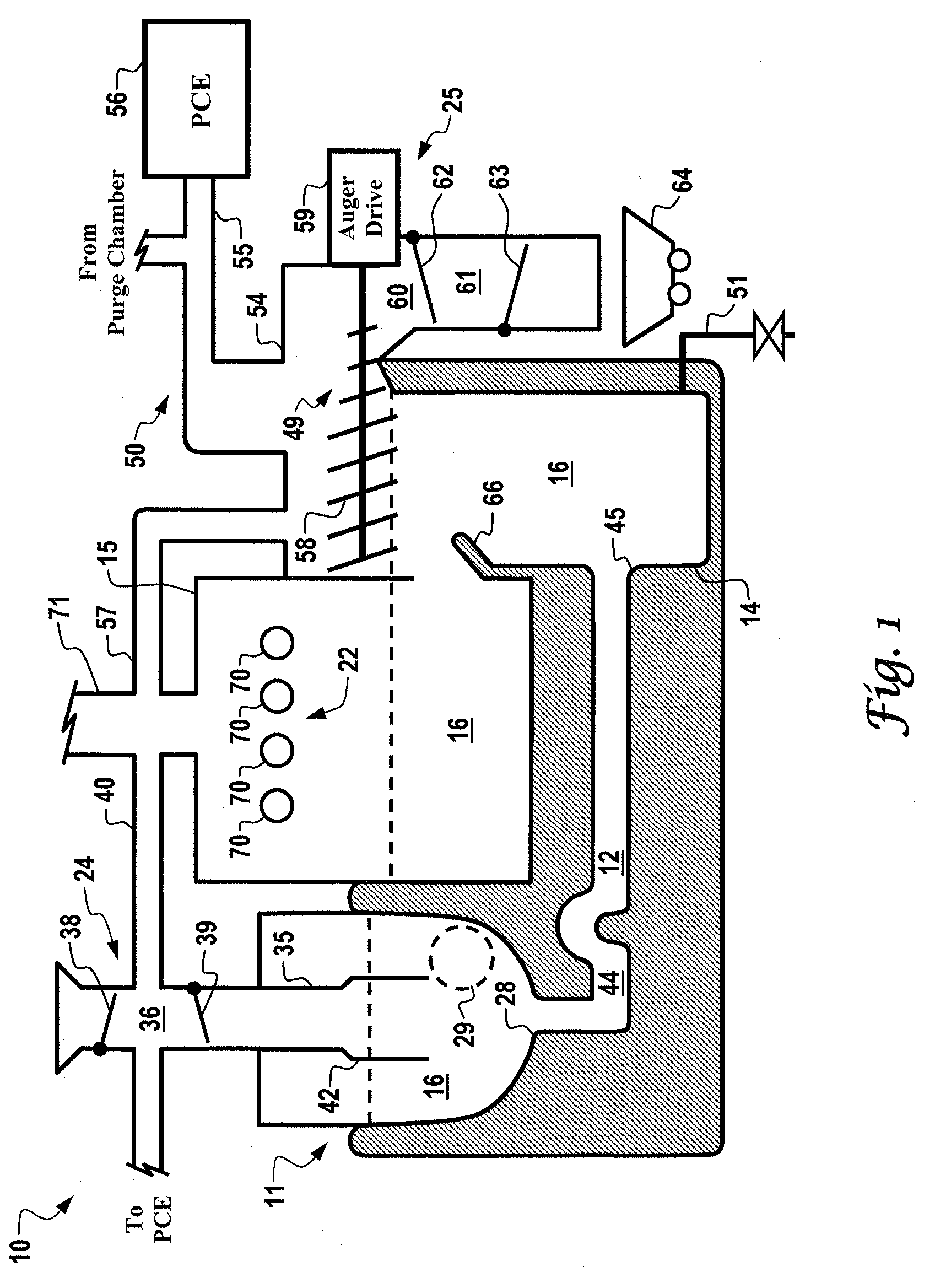

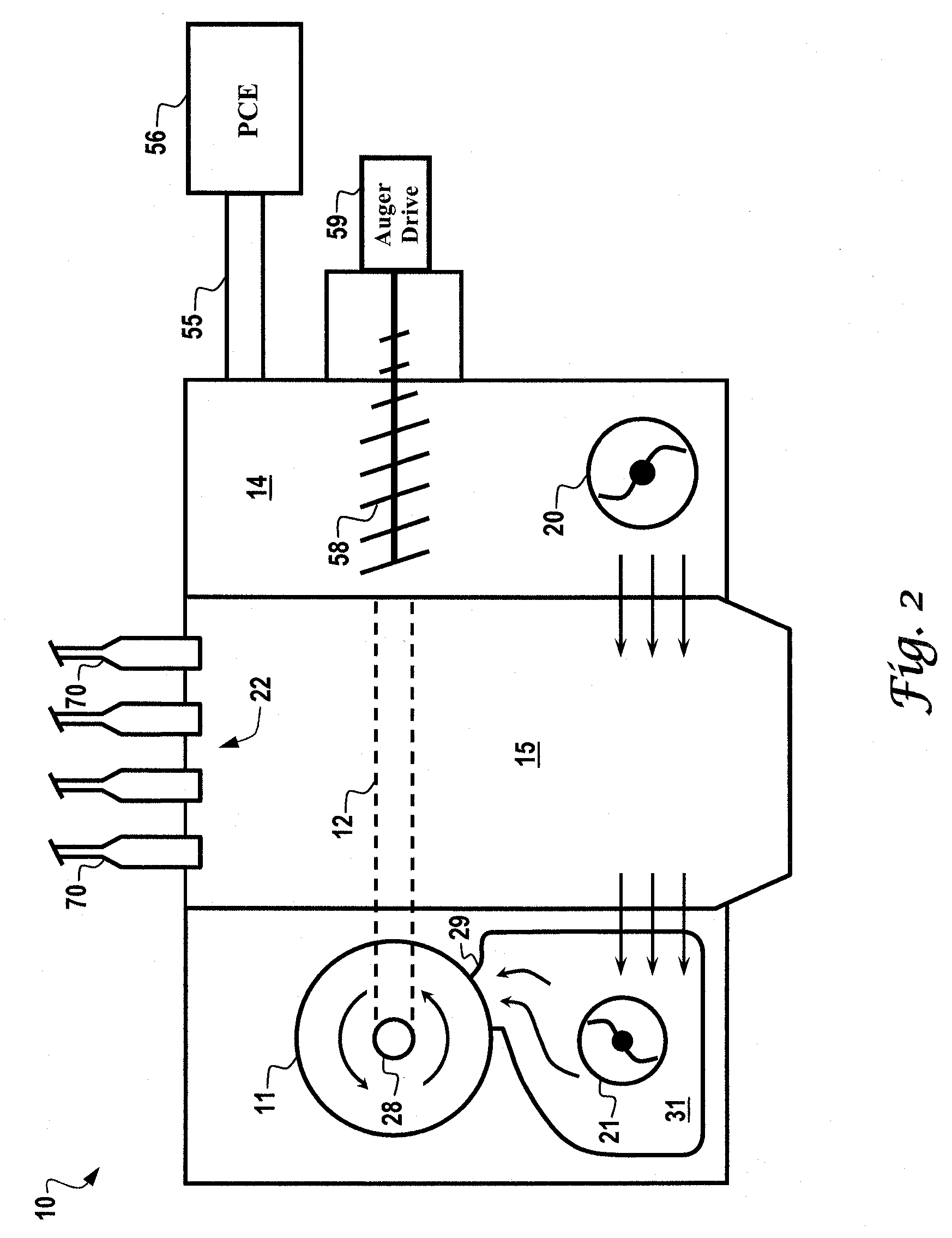

[0017]Referring particularly to FIGS. 1 and 2, a molten metal reactor 10 embodying the principles of the invention includes essentially four chambers including a bowl-shaped vortex or feed chamber 11, a treatment chamber 12, an output chamber 14, and a heating chamber 15. Each of these chambers is adapted to contain a molten reactant metal indicated by the reference numeral 16. The level of molten reactant metal 16 in feed chamber 11, output chamber 14 and heating chamber 15 is indicated by the dashed line in the respective chamber. Molten reactant metal 16 is heated to the desired temperature in heating chamber 15 and then transferred to feed chamber 11. From feed chamber 11, molten reactant metal 16 flows rapidly into treatment chamber 12 and then exits the treatment chamber into output chamber 14. From output chamber 14, molten reactant metal 16 returns to heating chamber 15 for reheating and recycling through the reactor 10. Reaction products are removed from reactor 10 through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| residence time | aaaaa | aaaaa |

| chemical reduction | aaaaa | aaaaa |

| melt | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com