Method and apparatus for performing three-dimensional measurement

a three-dimensional measurement and measurement method technology, applied in the direction of measuring devices, instruments, using optical means, etc., can solve the problems of fatal damage, defective generation, and incorrect three-dimensional coordinate computation results, so as to reduce the accuracy of three-dimensional measurement, prevent poor accuracy, and reduce the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

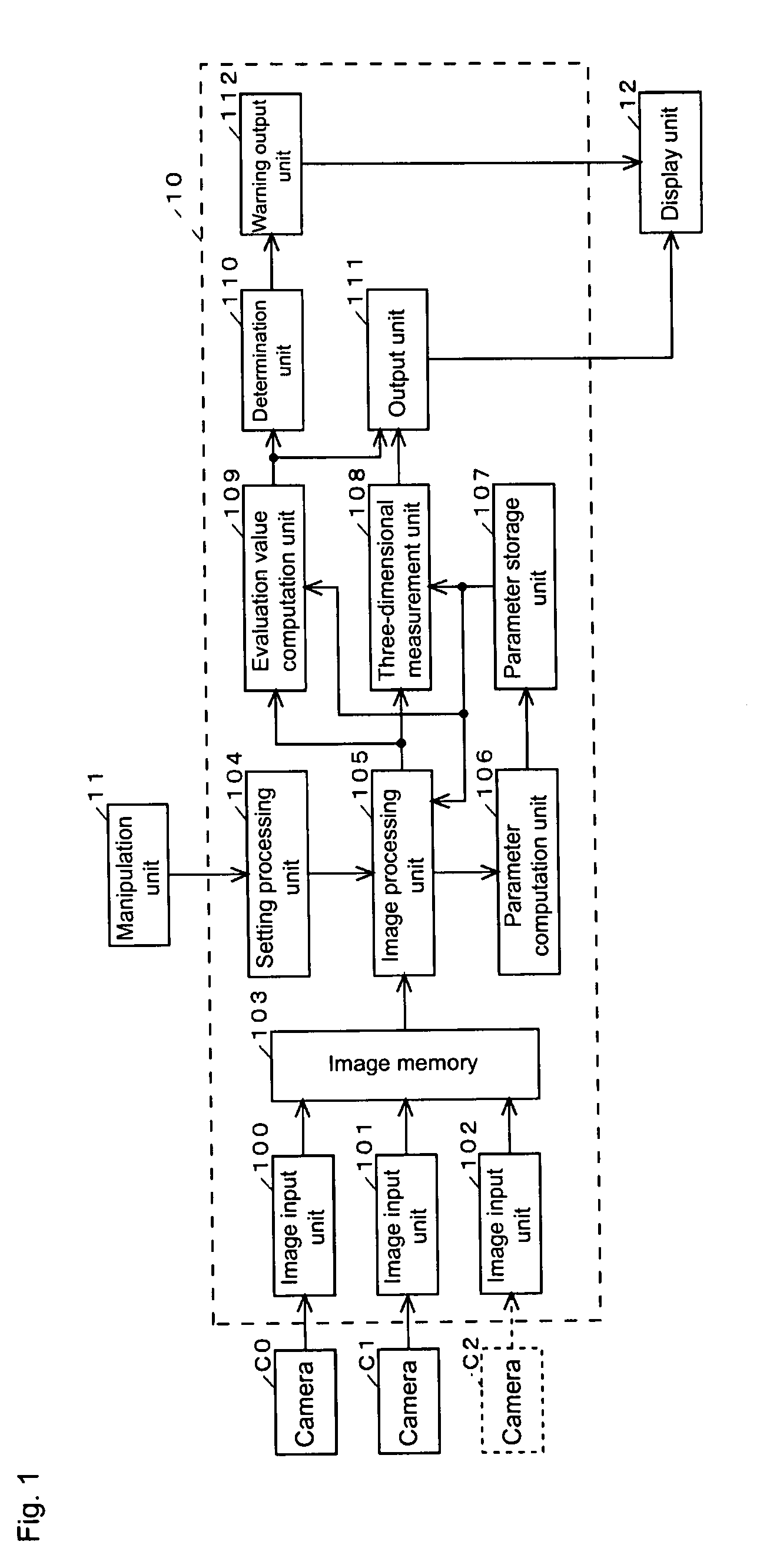

[0039]FIG. 1 shows a three-dimensional measurement apparatus according to an embodiment of the invention.

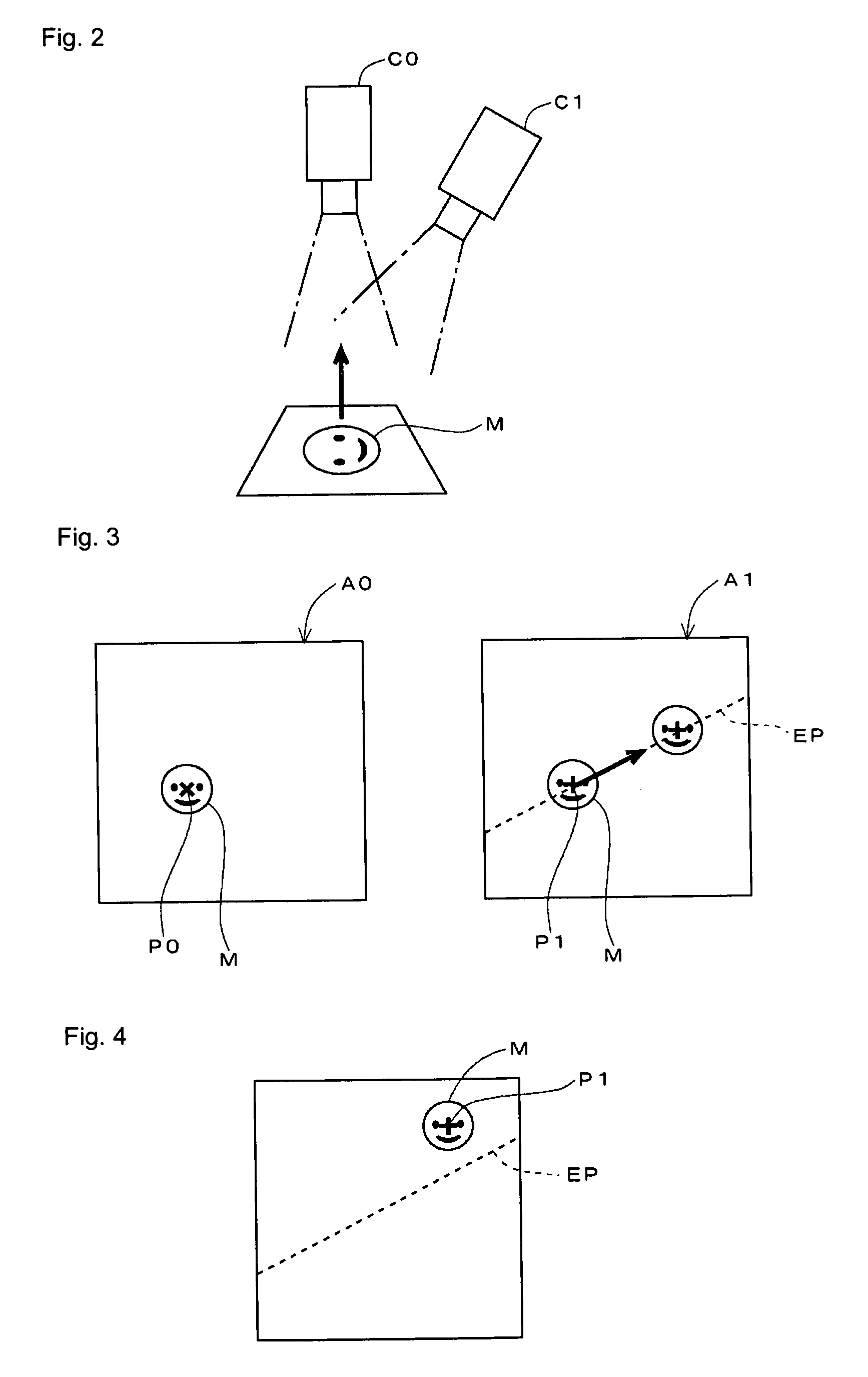

[0040]In a production line of a plant, the three-dimensional measurement apparatus sequentially delivers measuring objects having the same shape to a processing target region to perform the three-dimensional measurement using two or three cameras.

[0041]Referring to FIG. 1, a computer is incorporated in a control processing unit 10. Cameras C0, C1, and C2, a manipulation unit 11, and a display unit 12 are connected to the control processing unit 10. Because the third camera C2 can be connected if needed in the cameras C0, C1, and C2, a frame of the camera C2 is indicated by a broken line.

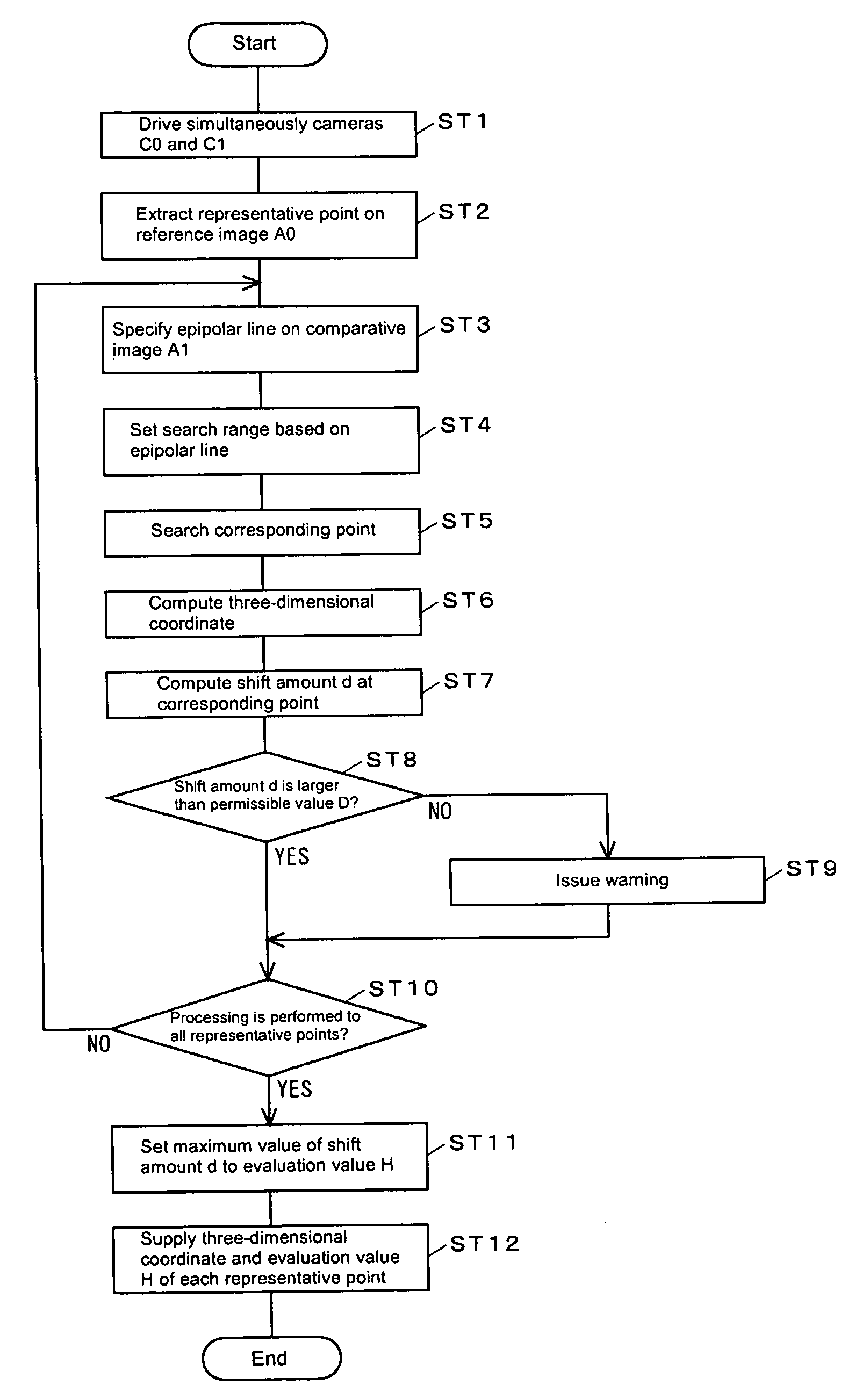

[0042]The control processing unit 10 includes image input units 100, 101, and 102 which correspond to the cameras C0, C1, and C2, an image memory 103, a setting processing unit 104, an image processing unit 105, a parameter computation unit 106, a parameter storage unit 107, a three-dimensional me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com