Heat exchanger and refrigeration cycle apparatus having the same

a technology of heat exchanger and refrigeration cycle, which is applied in the direction of indirect heat exchanger, light and heating apparatus, stationary plate conduit assembly, etc., can solve the problem that the heat exchanger cannot be easily made to have a thin shape, and achieve the effect of minimizing the dead zone, reducing the pressure loss of refrigerant, and improving the heat exchange performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

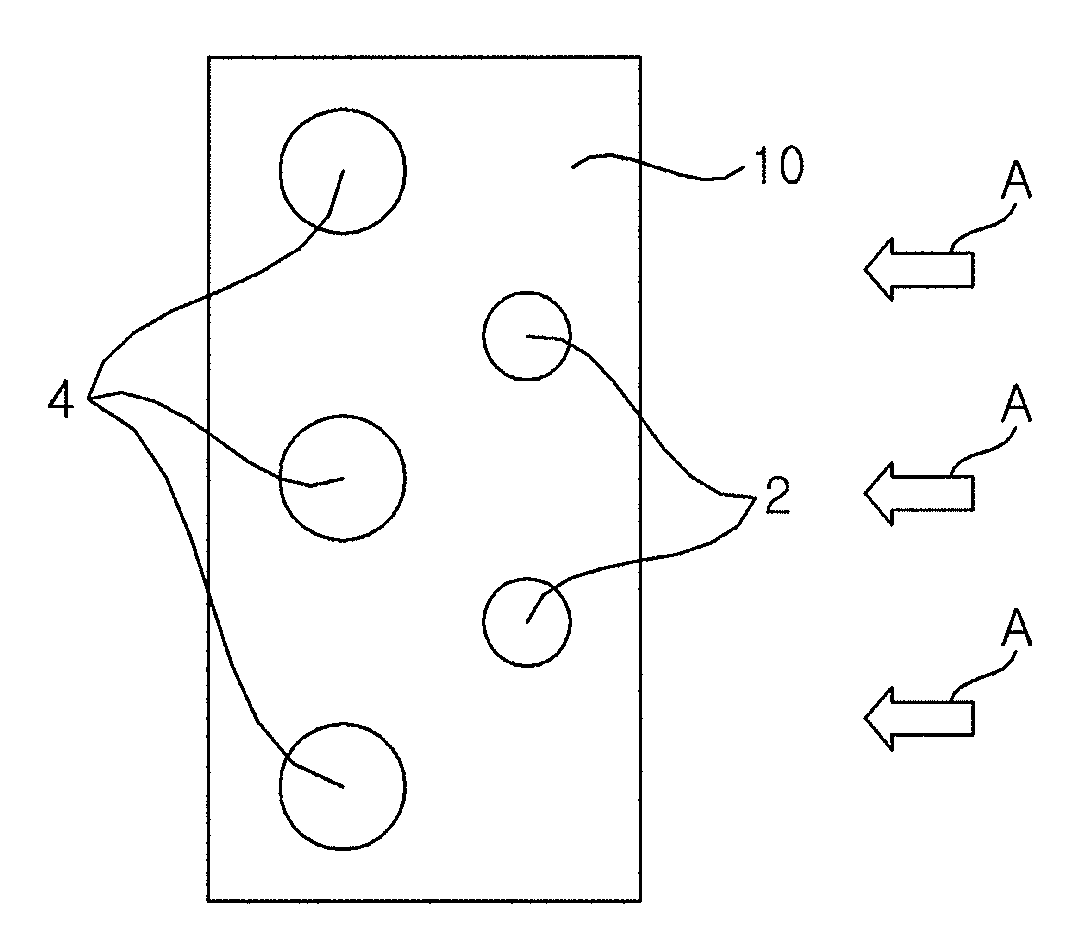

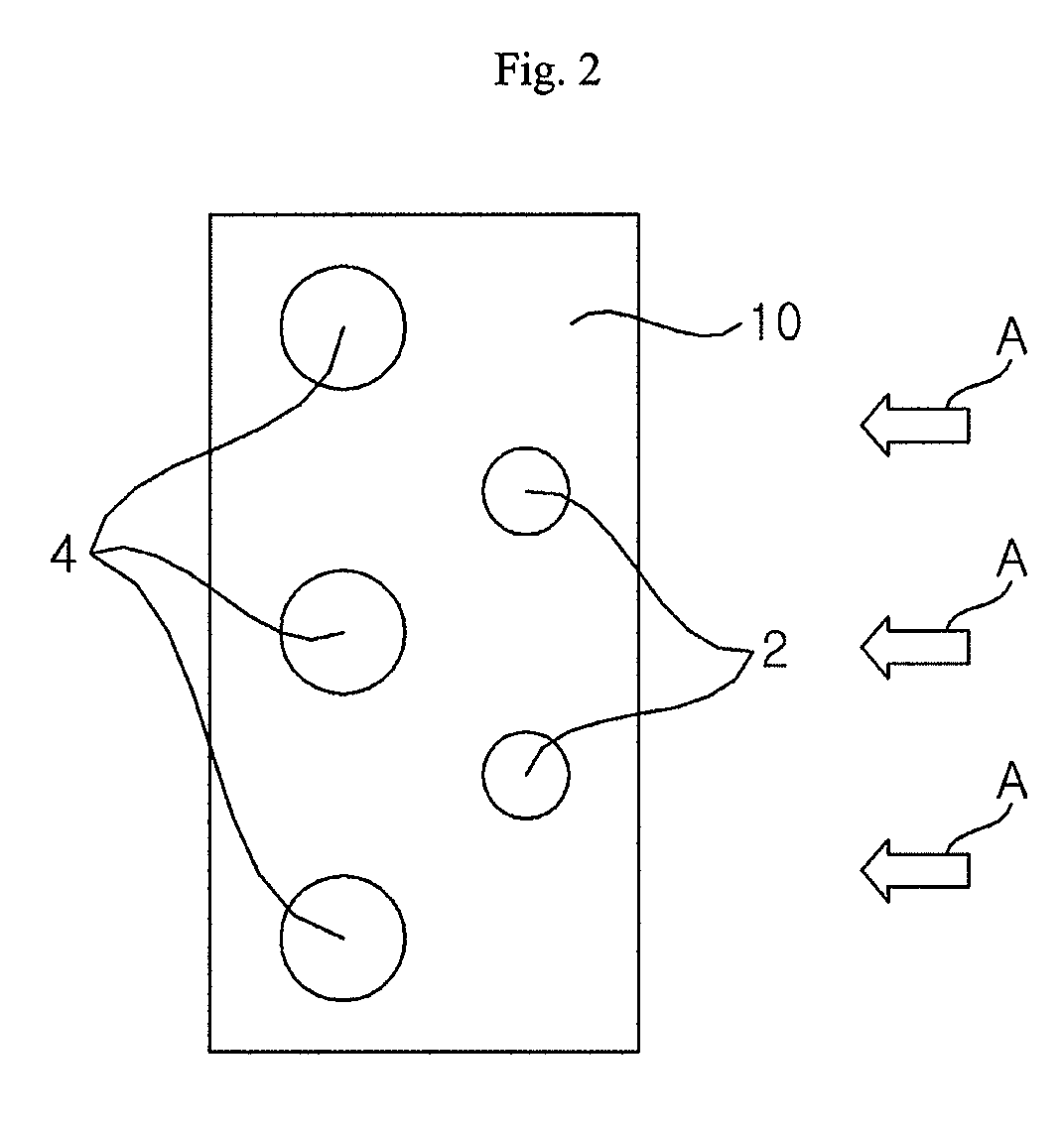

[0028]FIG. 2 is an overview illustrating a heat exchanger according to an embodiment of the present invention. As shown, the heat exchanger includes a plurality of columns of refrigerant tubes 2 and 4 through which refrigerant passes and fins 10 coupling the plurality of columns of refrigerant tubes 2 and 4. Further, the plurality of fins 10 are coupled to the refrigerant tubes 2 and 4 by a predetermined distance.

[0029]In addition, the refrigerant tubes 2 and 4 are longitudinally arranged to be orthogonal to the flowing direction of air A and the fins 10 are arranged to run parallel to the flowing direction of the air A. The refrigerant tubes 2 and 4 also include former columns of refrigerant tubes 2 positioned in the front in the air flowing direction and latter columns of refrigerant tubes 4 positioned in the rear. The former columns of refrigerant tubes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com