Fuel filter device

a filter device and fuel technology, applied in the direction of filtration separation, lubricant mounting/connection, separation process, etc., can solve the problems of fuel soaking and swollen nylon, increased pressure loss, and decreased mesh size of the filter body, so as to reduce the load on the fuel pump, increase the pressure of the fuel, and reduce the effect of fuel pump load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

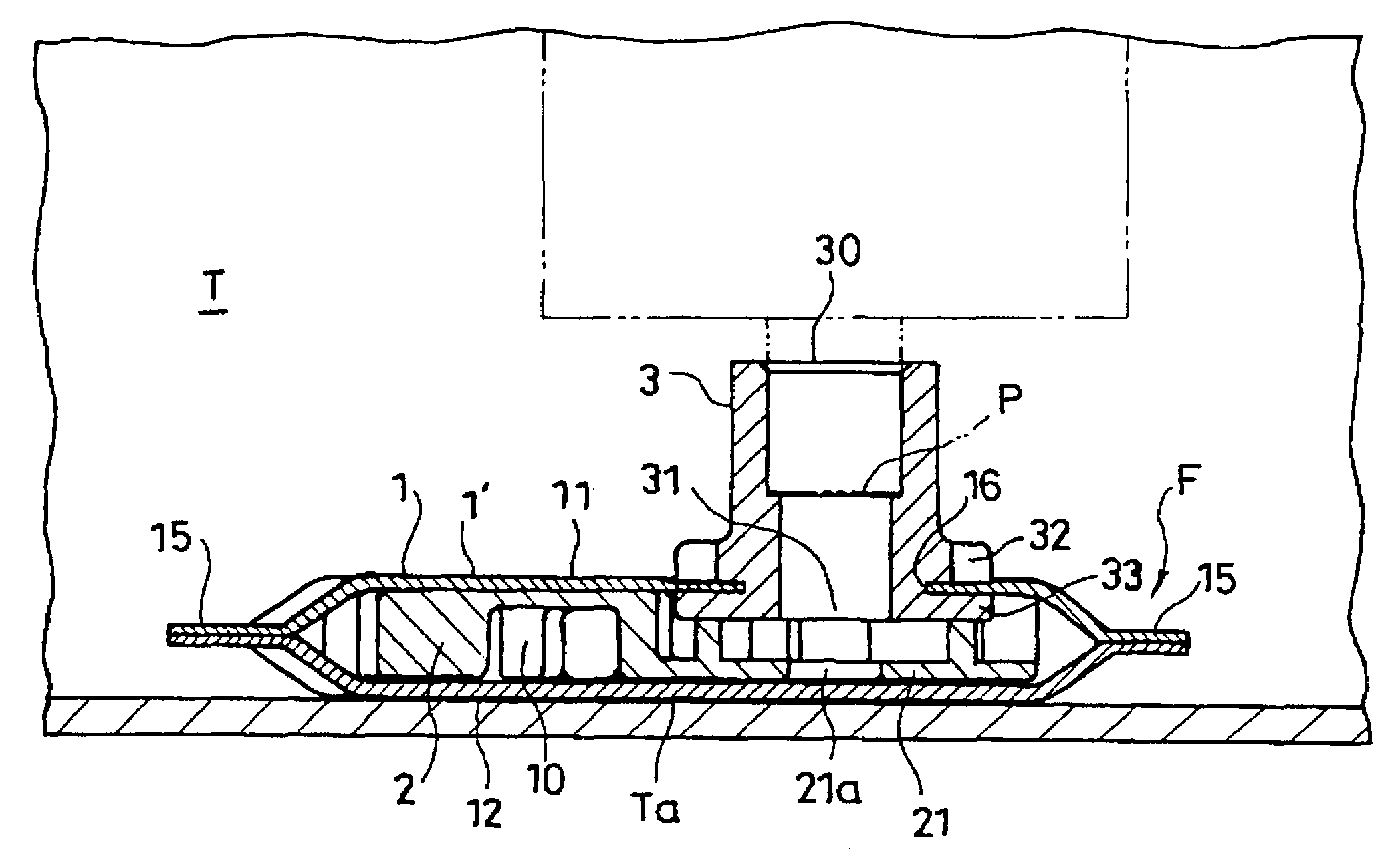

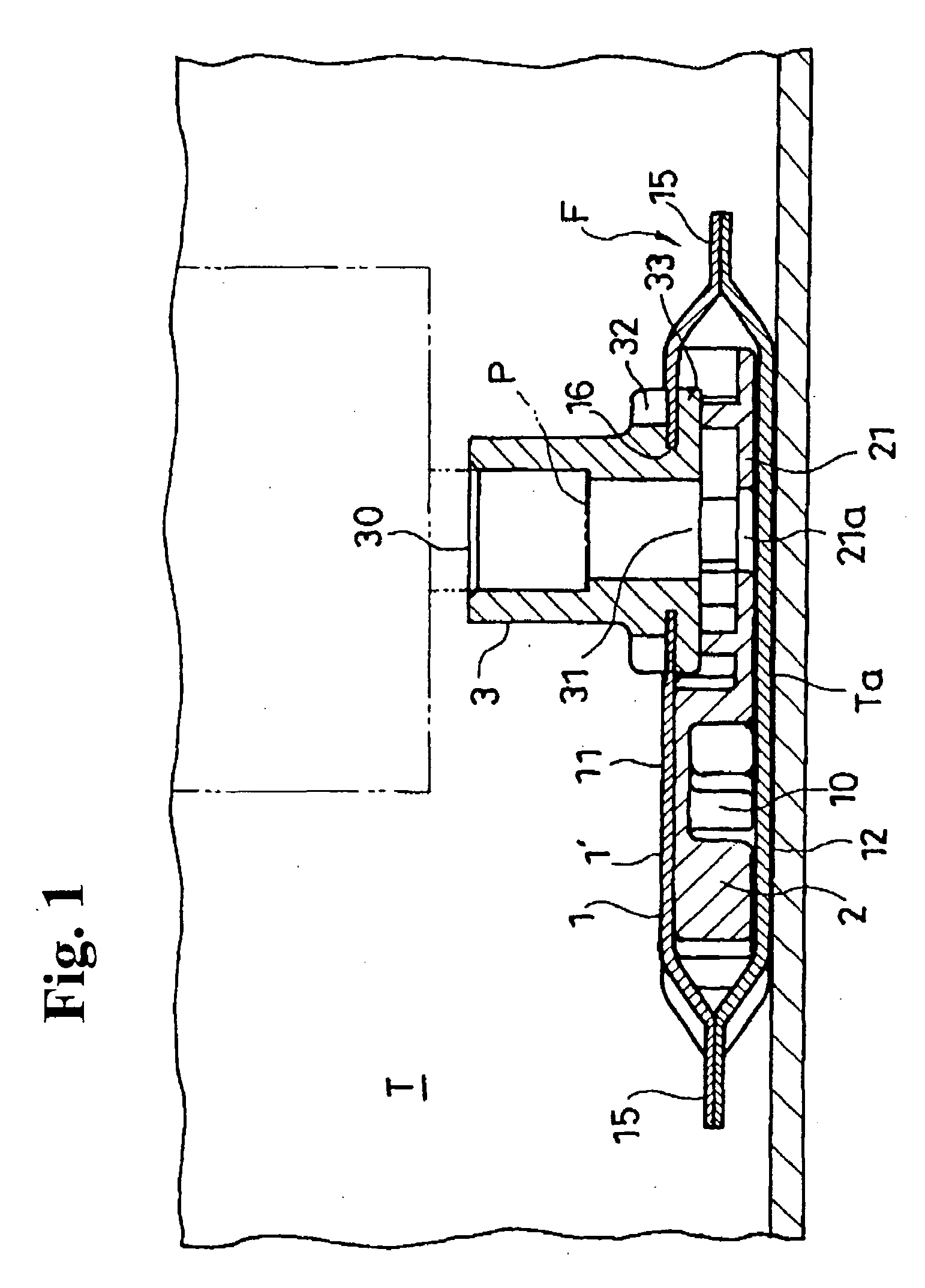

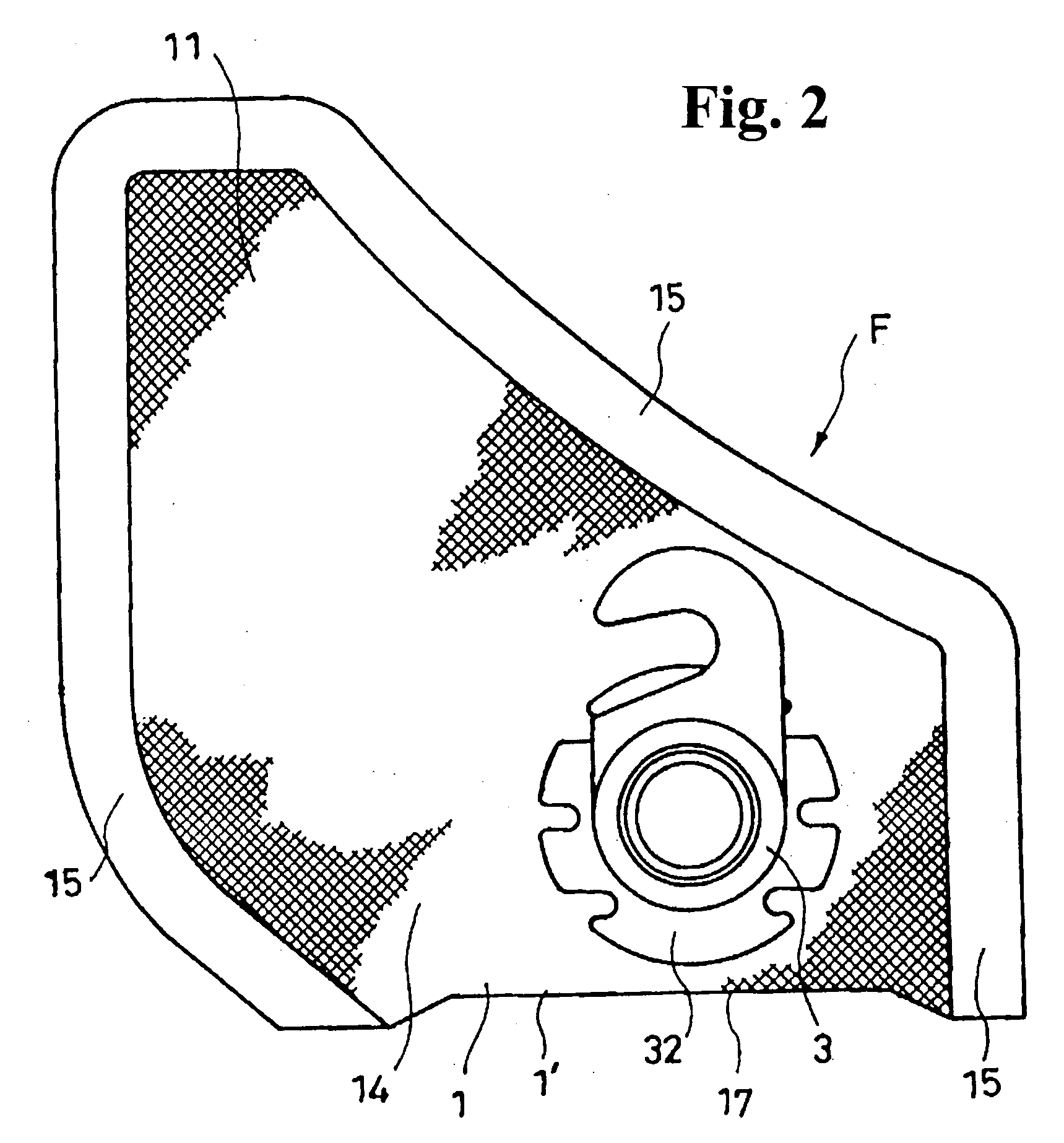

[0025]Hereunder, embodiments of the invention will be explained with reference to the accompanying drawings. FIG. 1 is a schematic view showing a state that a filter device F is installed on a fuel intake port P in a fuel tank T. FIG. 2 is a plan view of the filter device F. FIG. 3 is a side view of the filter device F. FIGS. 4 to 8 are views showing a state that a cylindrical socket body 3 is integrated with an expanded filter base member 1′ before forming a filter body 1 constituting the filter device F. FIGS. 9 to 11 are views showing a space forming member 2 housed inside the filter body 1 for maintaining the filter body 1 in an expanded shape in a state that the filter base member 1′ is integrally provided with the cylindrical socket body 3 and the filter base member 1′ is formed in a bag-shape. FIG. 12 is a sectional view showing an example of a structure of the filter body 1.

[0026]In the embodiment, the fuel filter device F is installed inside the fuel tank T of an automobile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| mesh size | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com