Overmolded grasper jaw

a grasper and jaw technology, applied in the field of surgical graspers, can solve the problems of high cost and time consumption of all these processes, and achieve the effects of facilitating the opening facilitating the closing of the jaw spine, and increasing the mechanical advantage of opening the jaw spin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

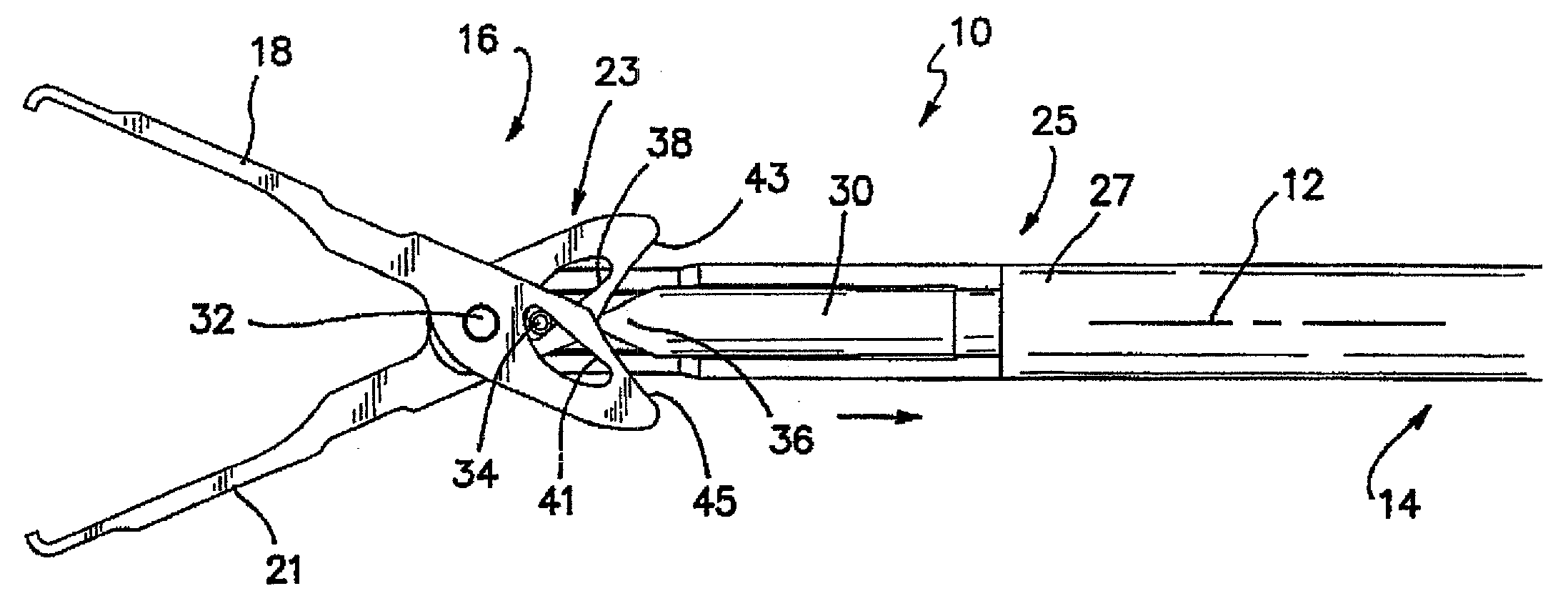

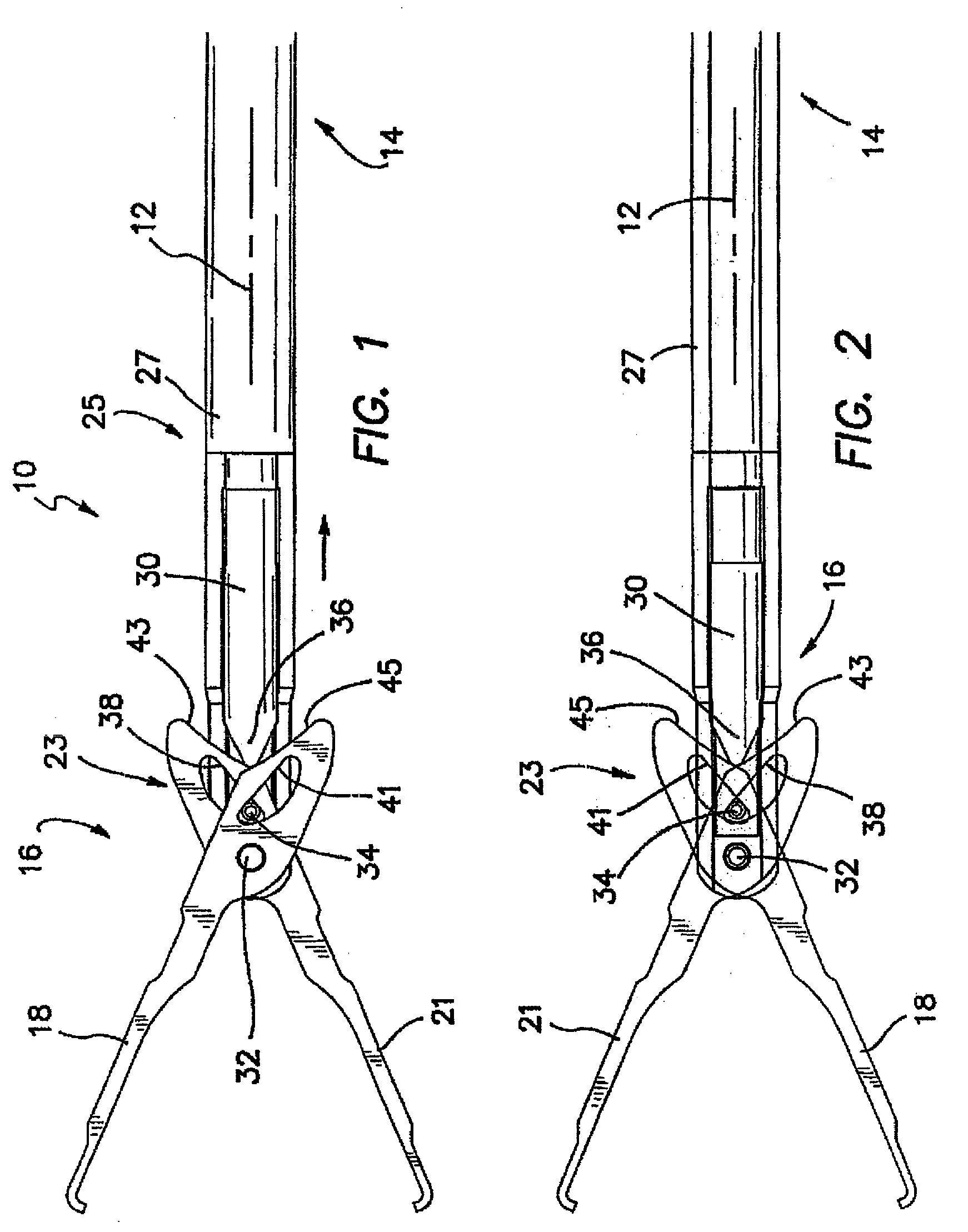

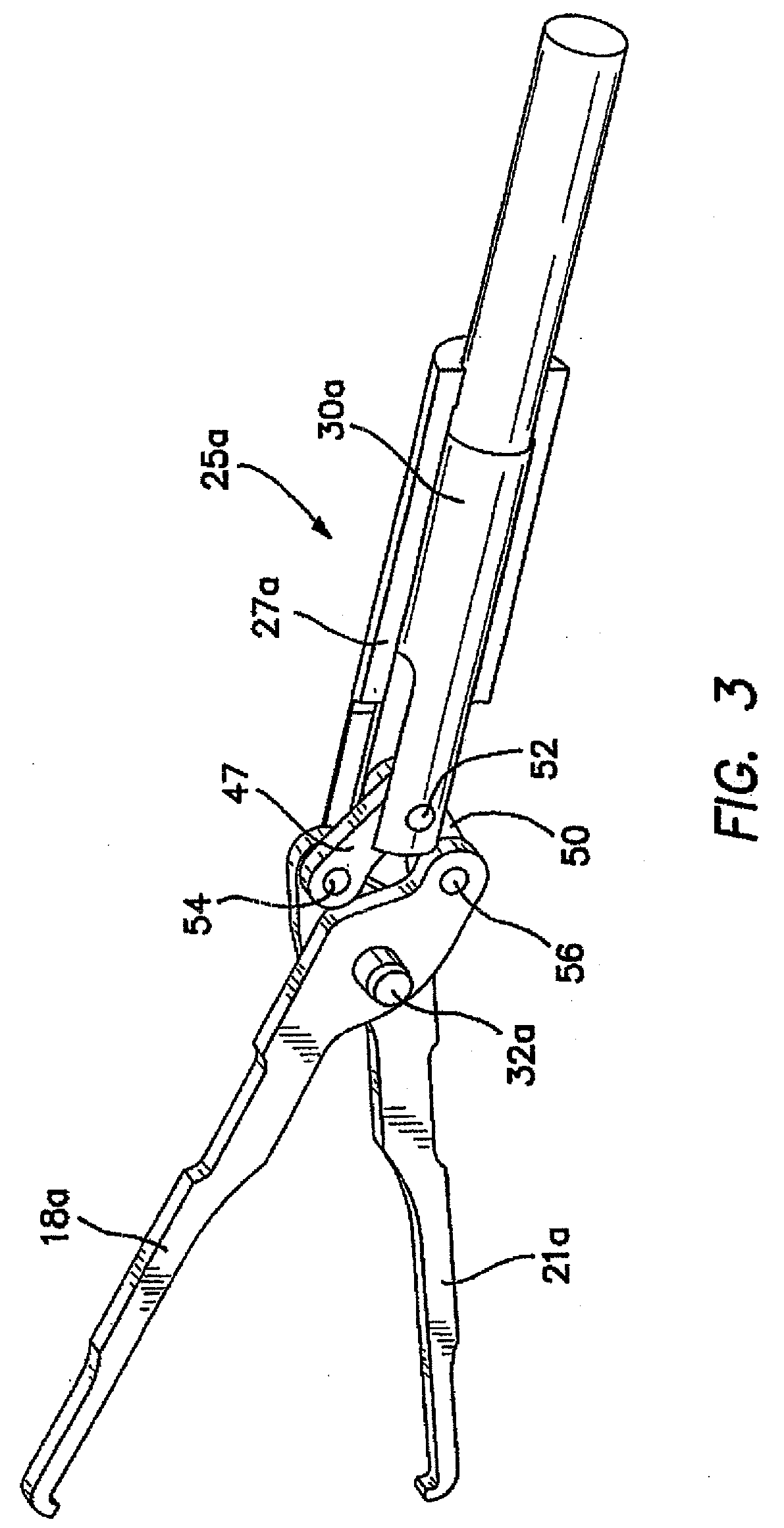

[0032]A surgical grasper is illustrated in FIG. 1 and designated by the reference numeral 10. The grasper is an elongate device having an axis 12 which extends between a proximal end 14 and a distal end 16. A pair of opposing jaw spines 18 and 21, disposed at the distal end 16, are operable between opened and closed positions by an actuation mechanism 23. A shaft assembly 25 extends along the axis 12 and includes an outer tube 27 and an inner actuation rod 30. The spines 18 and 21 are pivotally attached to the outer tube 27 by a common pivot pin 32.

[0033]The actuation mechanism 23 includes a distal camming pin 34 and a proximal camming projection 36. Both the pin 34 and projection 36 are carried by the actuation rod 30 which is moveable axially within the outer tube 27.

[0034]The camming pin 34 rides on two interior camming surfaces 38 and 41 each of which defines a slot in one of the jaw spines 21 and 18, respectively. When the actuation rod 30 is moved proximally, the camming pin 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com