Travel unit for mobile machines

a technology for mobile machines and travel units, applied in the direction of machine supports, supplementary fittings, vehicle maintenance, etc., can solve the problem that the known design requires a large production effort, and achieve the effect of reducing production effort and minimizing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

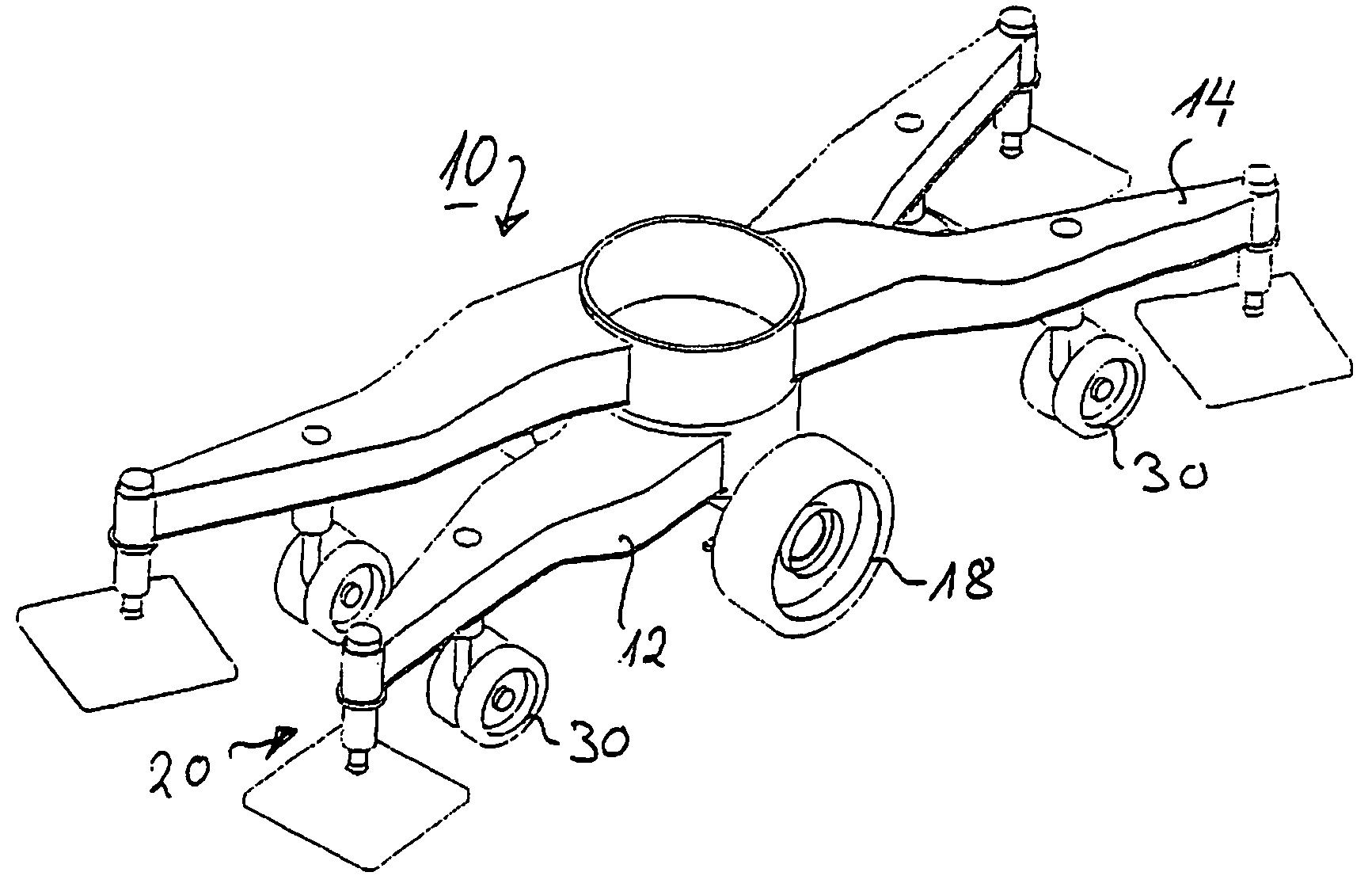

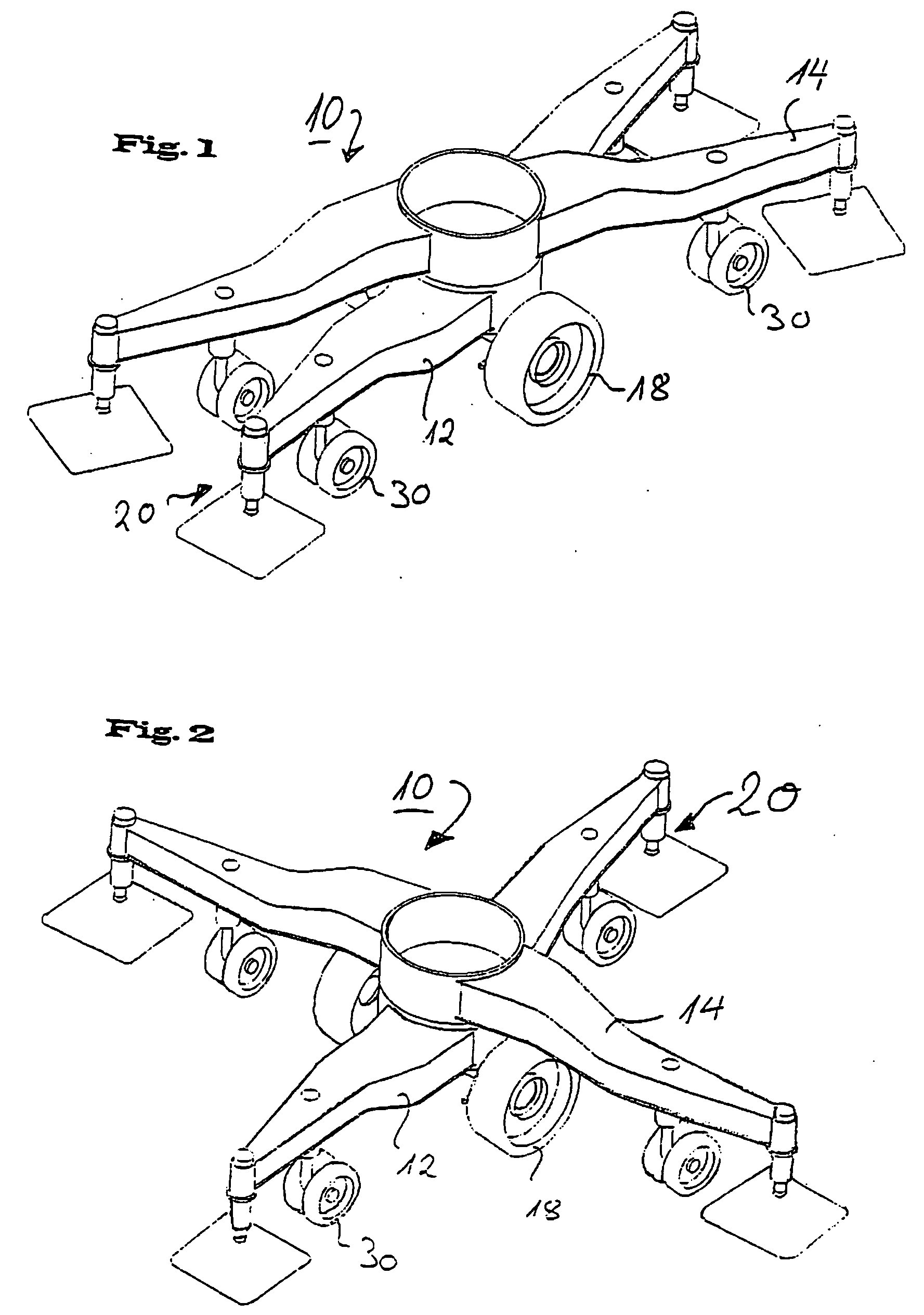

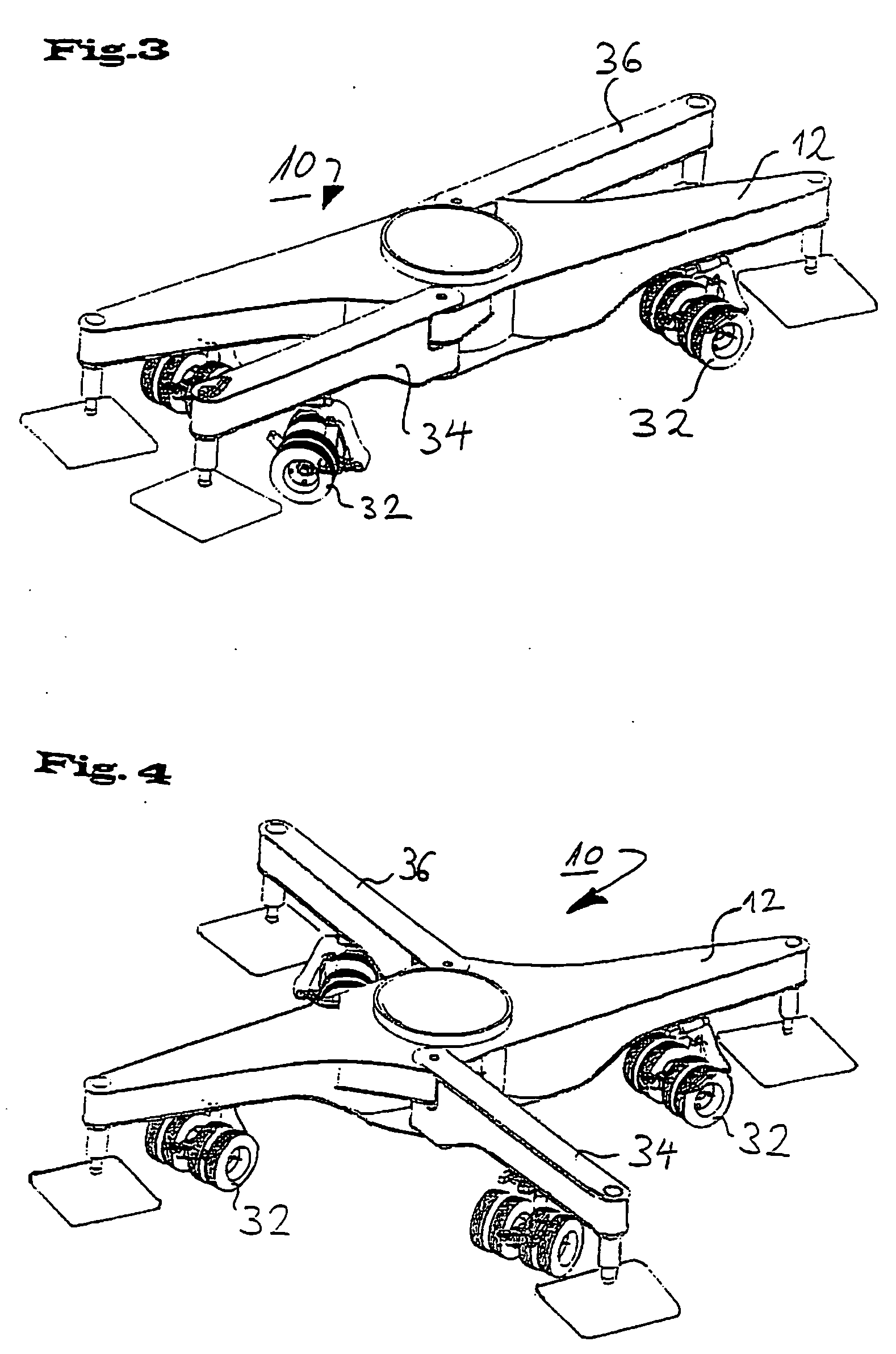

[0018]A first variant of a mobile unit 10 is shown in FIGS. 1 and 2 which has a rigid continuous support 12 which is pivotably connected to a second continuous rigid support 14 via a rotary joint not shown more closely in detail here. Support devices 20, which substantially consist of support plates 22 which can be extended or retracted via adjustment devices 24, are arranged on or after the respective ends of the continuous rigid supports 12 and 14.

[0019]The continuous rigid supports 12 and 14, which are connected to one another via spherical turntables, each have turntable supports 26 at their centers. The rotating deck of the superstructure of the machine can be placed in the usual manner on the turntable support 26 of the rigid continuous support 14. Since these are known designs, this is not shown in any more detail in the drawing.

[0020]A single wheel drive with individual wheels 18 is arranged by means of a further rotary joint which is not shown in any more detail here and wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com