Liquid cooling system for internal combustion engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

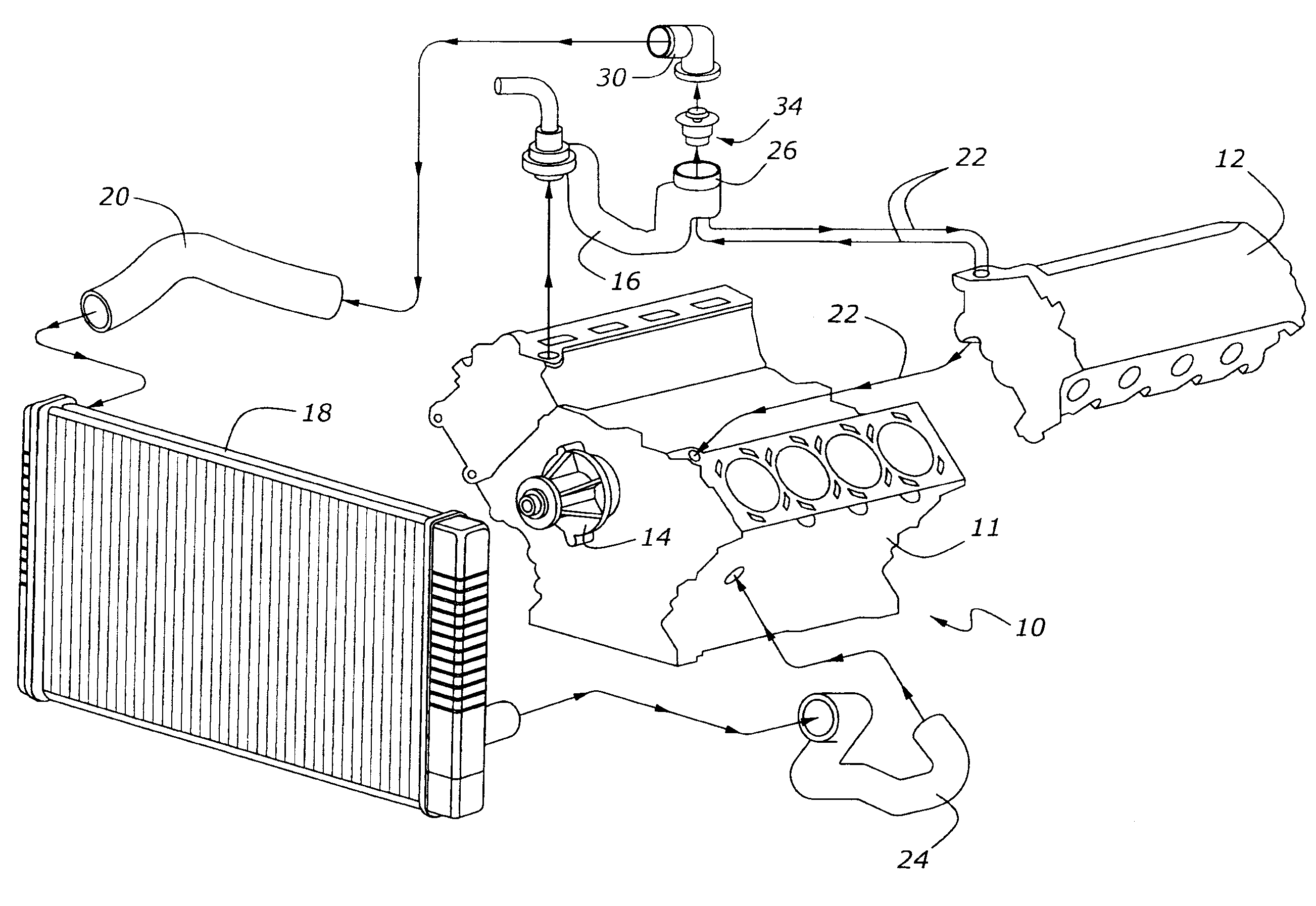

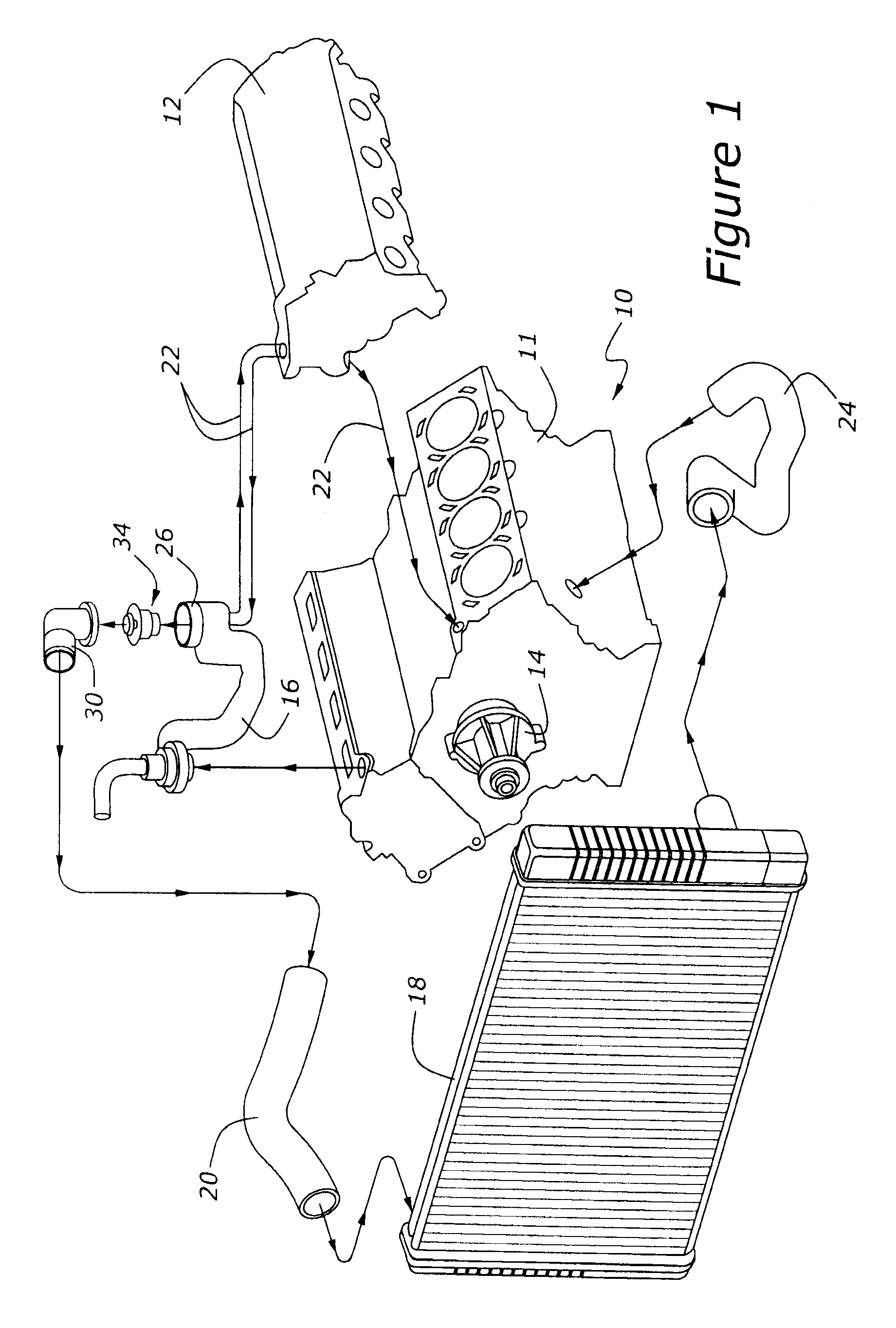

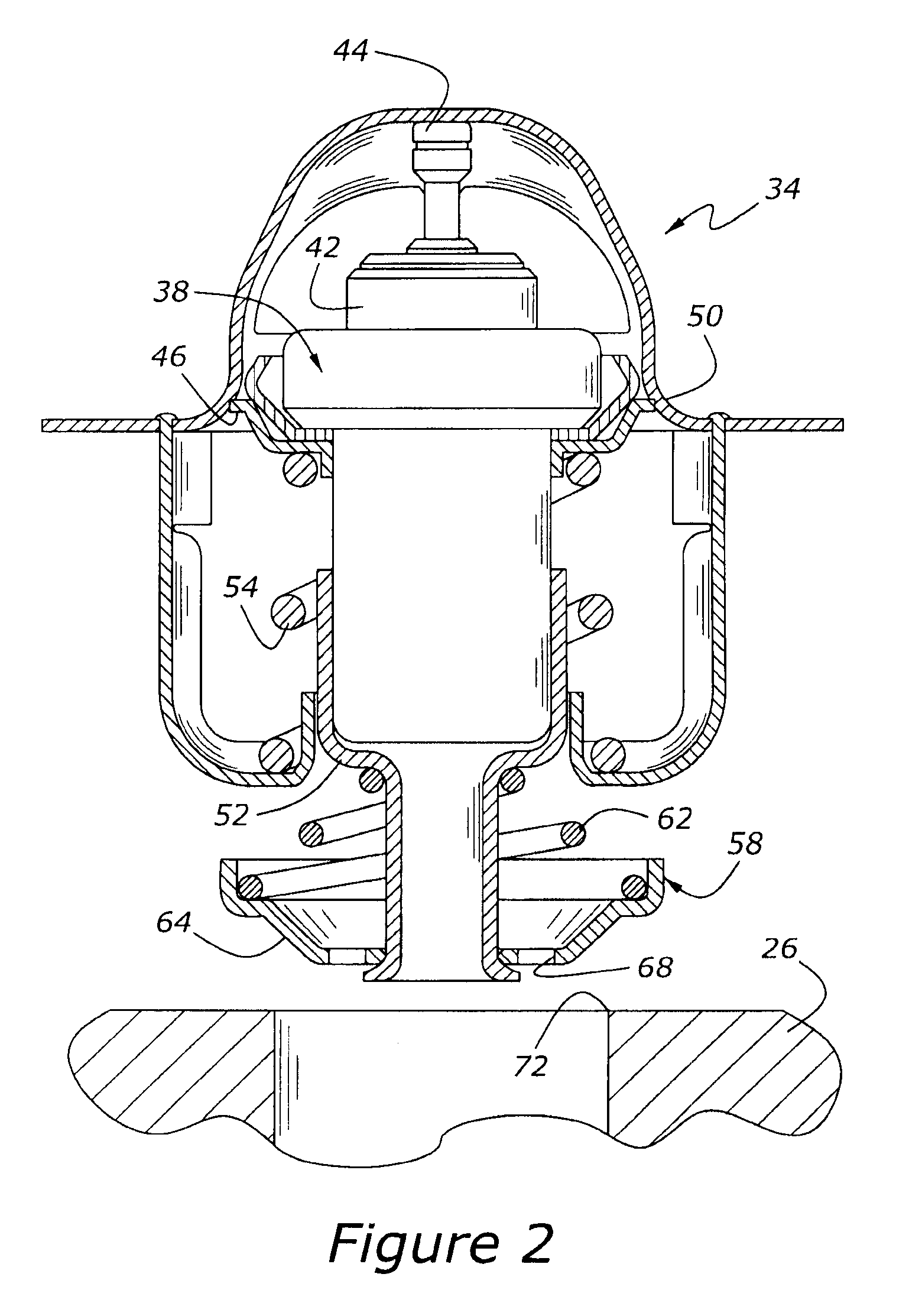

[0019]As shown in FIG. 1, engine 10 has a cylinder block, 11, upon which a pair of cylinder heads, 12, are mounted, with only one of cylinder heads 12 being shown. Engine 10 also includes a coolant pump, 14, a coolant crossover, 16, an air-to-liquid heat exchanger (“radiator”) 18, and a series of hoses. Coolant circulates generally from water pump 14 through cylinder block 11 and up through cylinder heads 12. After moving through cylinder heads 12, coolant flows into thermostat housing 26 which, as its name implies, provides a mounting place for thermostatic valve 34, including a bypass valve seat, 72 (FIGS. 2 and 3). When thermostatic valve 34 is in the open position shown in FIG. 3, coolant flows up through thermostatic valve 34 and then through coolant outlet 30 and upper radiator hose 20, and then into radiator 18. The cooled fluid then moves through lower radiator hose 24 and then through water pump 14. Leaving water pump 14, the fluid flows back through cylinder block 11, as d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com