Measuring system and measuring method for particle flow parameters

A flow parameter and measurement system technology, applied in the field of particle flow parameter measurement system, can solve the problems of temperature drift, affecting the accurate measurement of particle concentration, etc., to achieve the effects of improving reliability, preventing temperature drift, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention is described in detail:

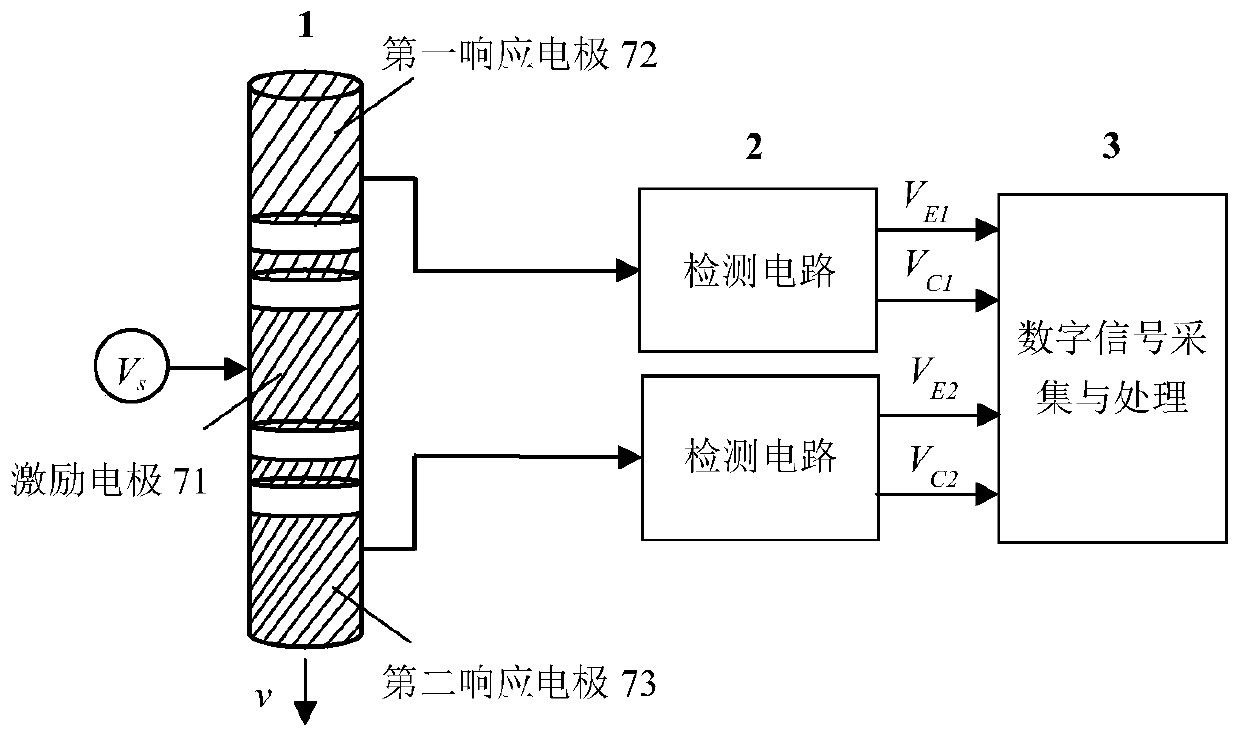

[0035] figure 1 It is a schematic block diagram of a particle flow parameter measurement system, including a sensor device 1 , a detection circuit 2 , and a digital signal acquisition and processing module 3 .

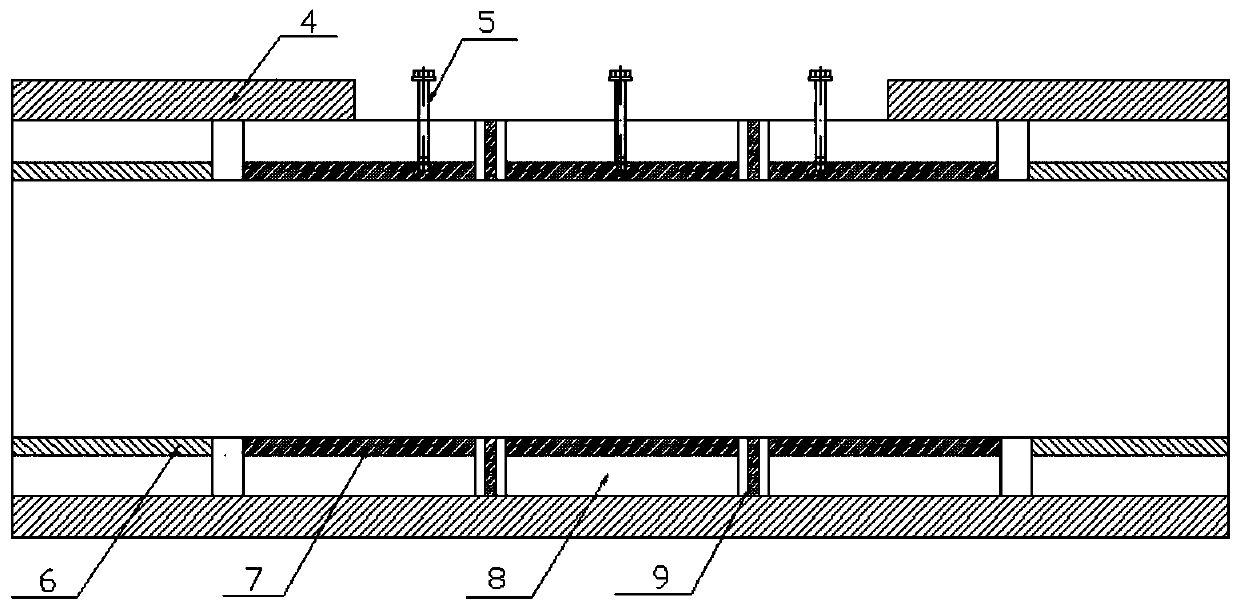

[0036] The structure of the sensor device 1, such as figure 2 As shown, it includes an excitation electrode 71 and two response electrodes 72 , 73 , an outer sleeve 4 , a conductive screw 5 , an inner sleeve 6 , an insulating ring 8 and two protective electrodes 9 . The parts are put together by extrusion.

[0037] The ring 8 of insulating material and the two protection electrodes 9 form an isolation protection unit, and the isolation unit is arranged at a space between the response electrode and the excitation electrode.

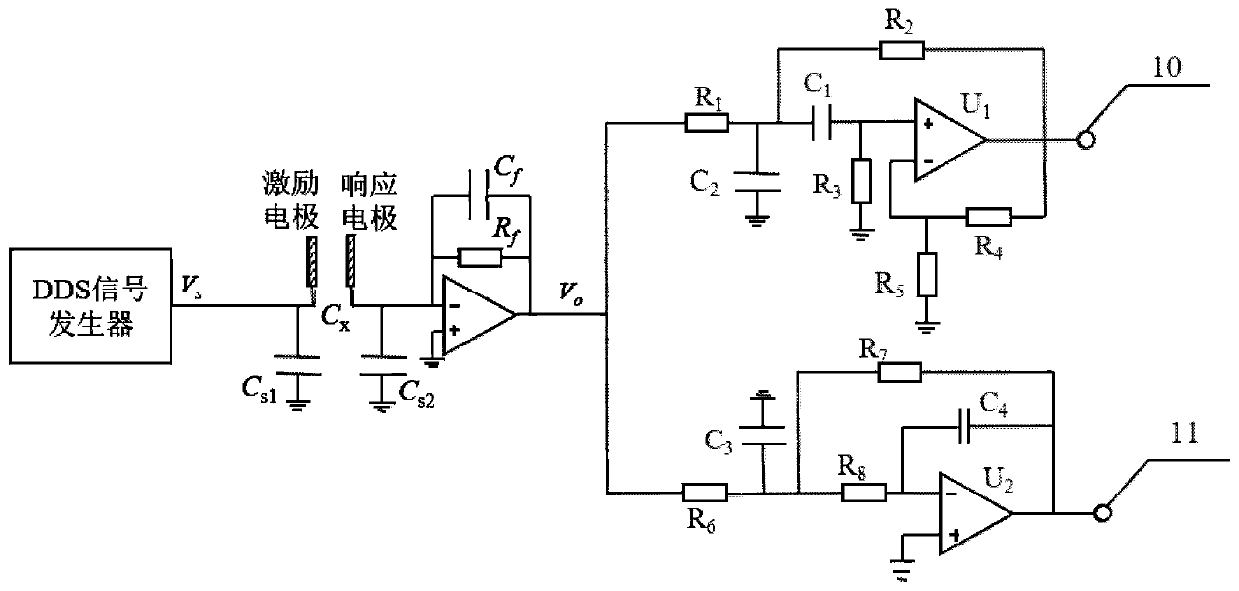

[0038] There are two detection circuits 2, which are respectively connected to a response electrode for extracting the capacitance signal and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com