Packaging unit for articles with opening feature

a packaging unit and opening feature technology, applied in the field of semirigid packaging units, can solve the problems of inconvenient user and difficulty in opening, and achieve the effect of convenient user grasping and a large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

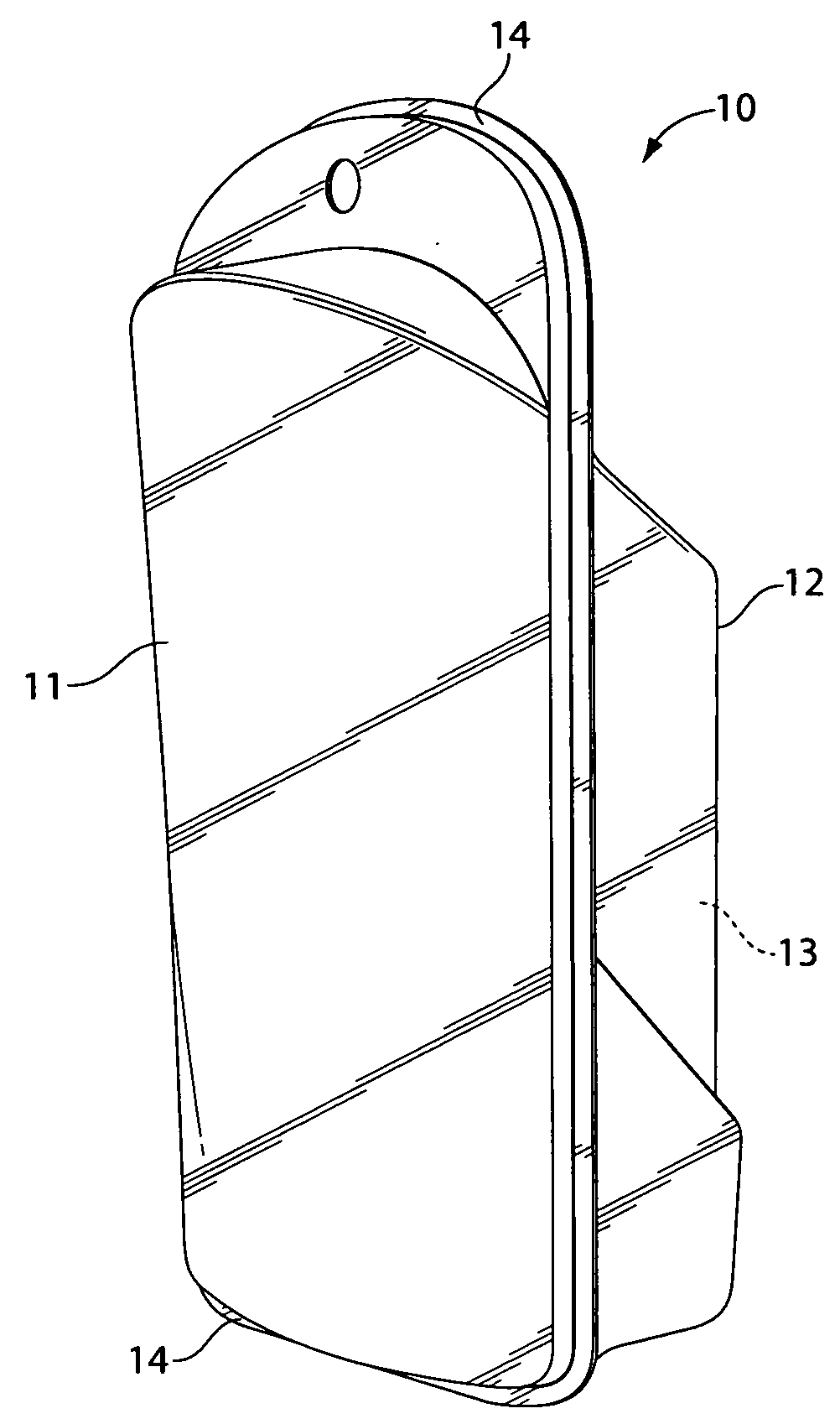

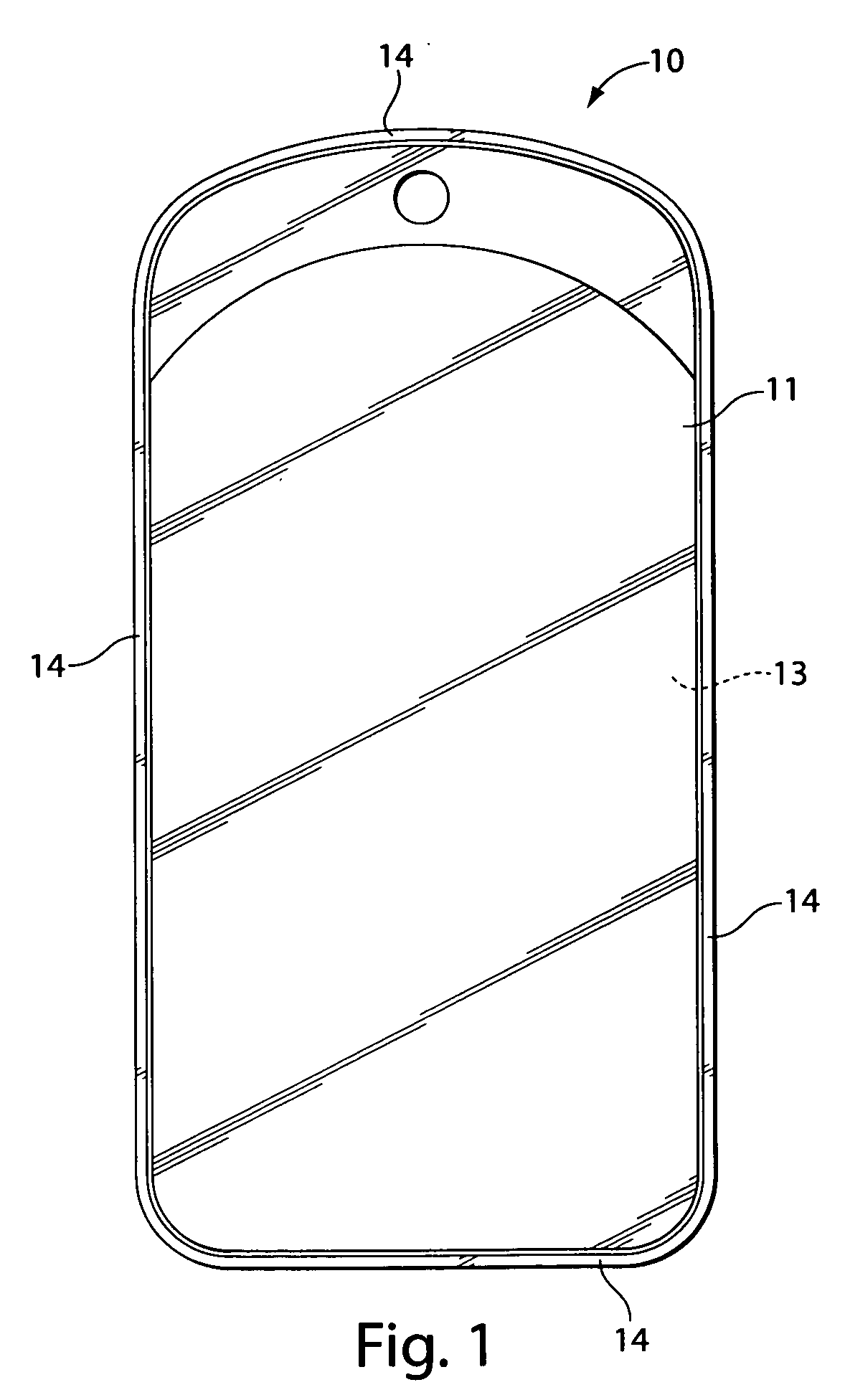

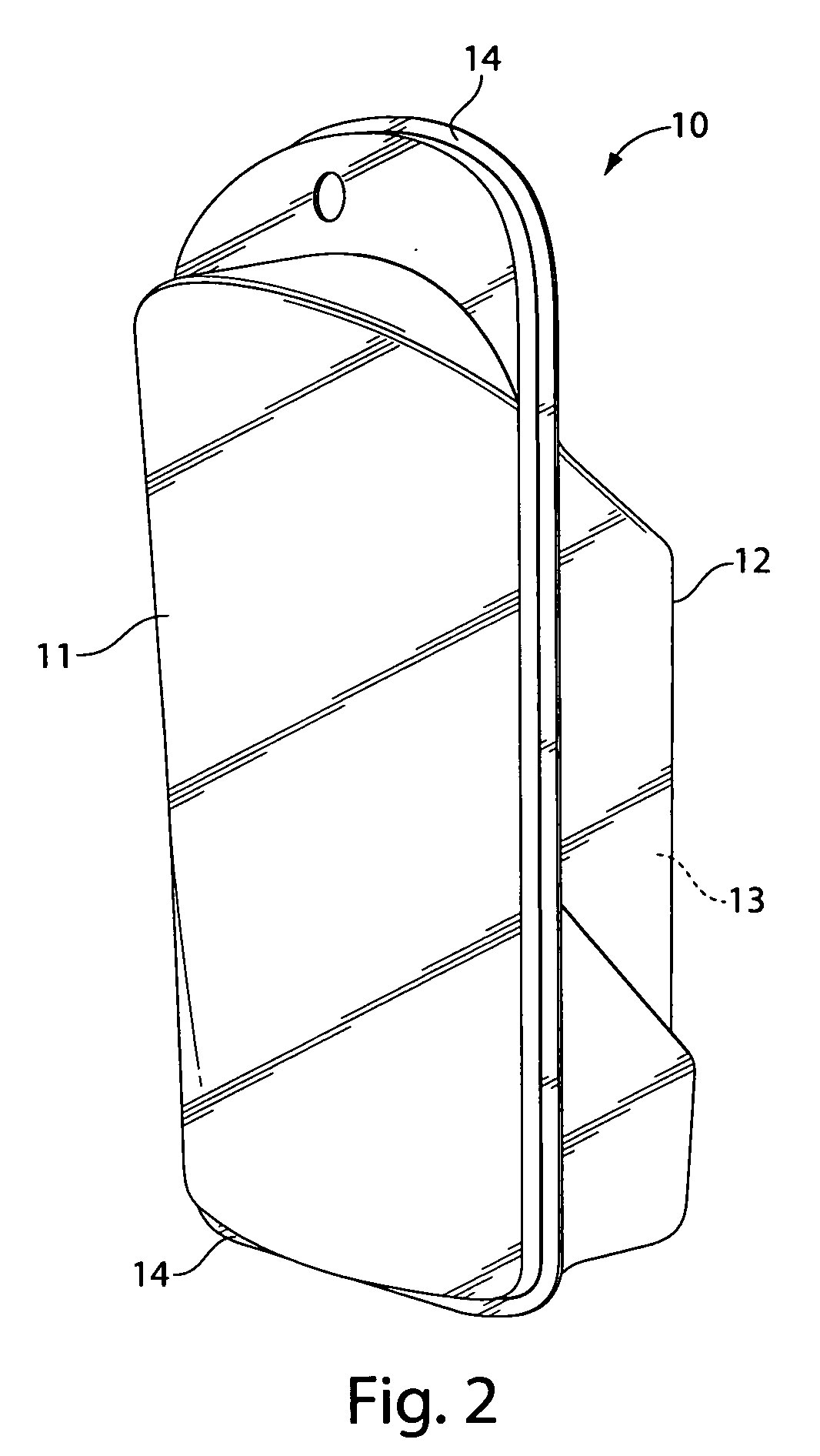

[0018]Referring to FIGS. 1 through 3, there is shown a packaging unit 10 for articles. The packaging unit 10 is comprised of two spaced-apart walls, front wall 11 and back wall 12 that have been formed to define an article-receiving region 13 between them commonly referred to as a blister, pouch, pocket or cavity. The walls can be referred to as a sheet, foil or panel. The article-receiving pouch shape can be formed into one wall and the other be flat, but it is preferred that both front wall 11 and back wall 12 define parts of the article-receiving pouch. The packaging unit 10 may have a plurality of shapes, including rectangular, circular or oval; preferably, in general, having a rectangular shape. The front wall 11 and back wall 12 are formed of semi-rigid material, which generally retains a shape, e.g. the blister shape, into which it is formed, and is relatively stiff. Preferably the front wall 11 and back wall 12 are formed of plastic material, preferably transparent plastic, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com