Exhaust purification system, control apparatus and control method therefor

a technology of exhaust fuel valve and purification system, which is applied in the direction of exhaust treatment electric control, mechanical equipment, machines/engines, etc., can solve the problem of not being able to specify the reason why the exhaust temperature does not rise sufficiently, oxidation catalyst or exhaust fuel valve may have to be replaced unnecessarily,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

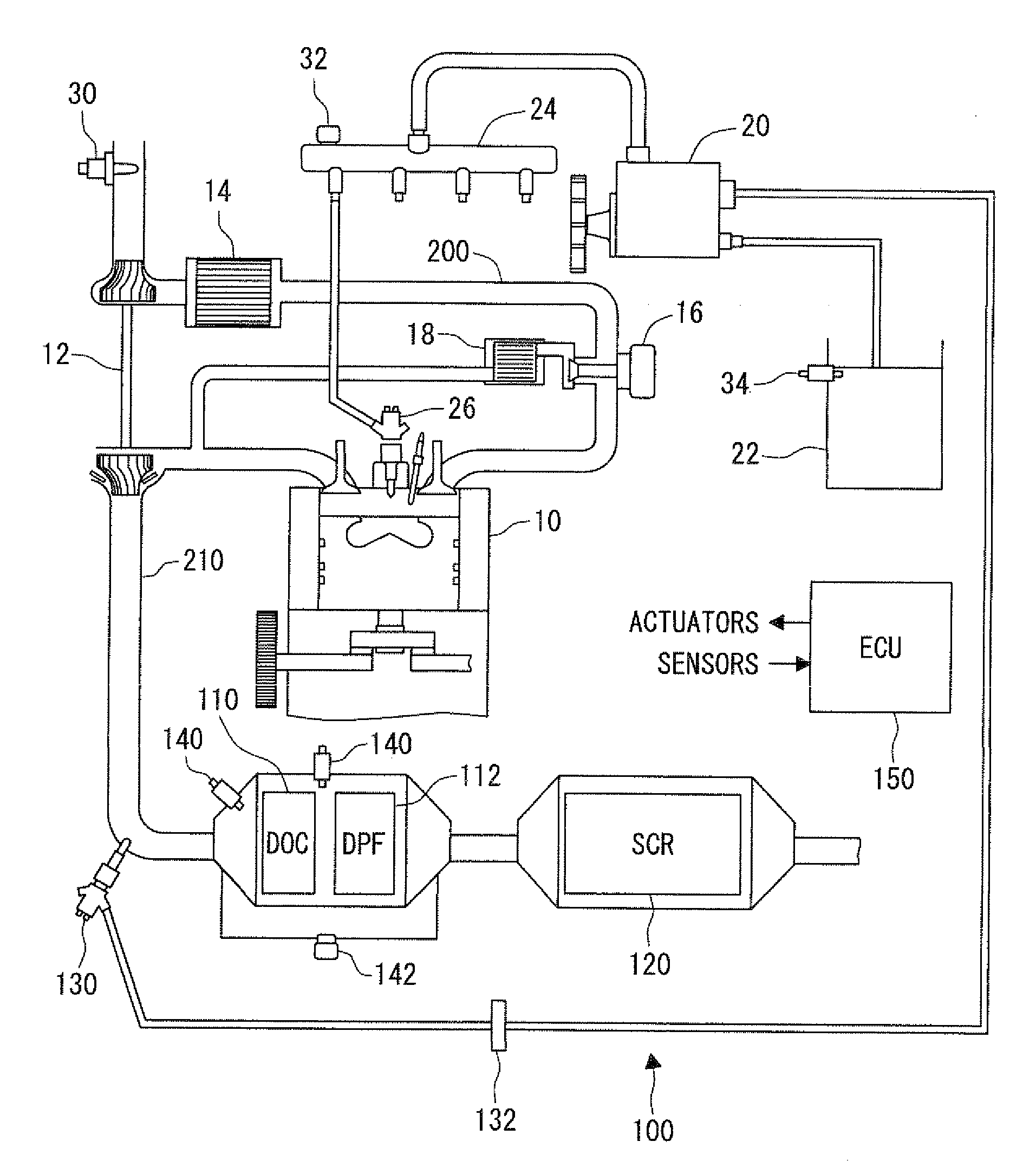

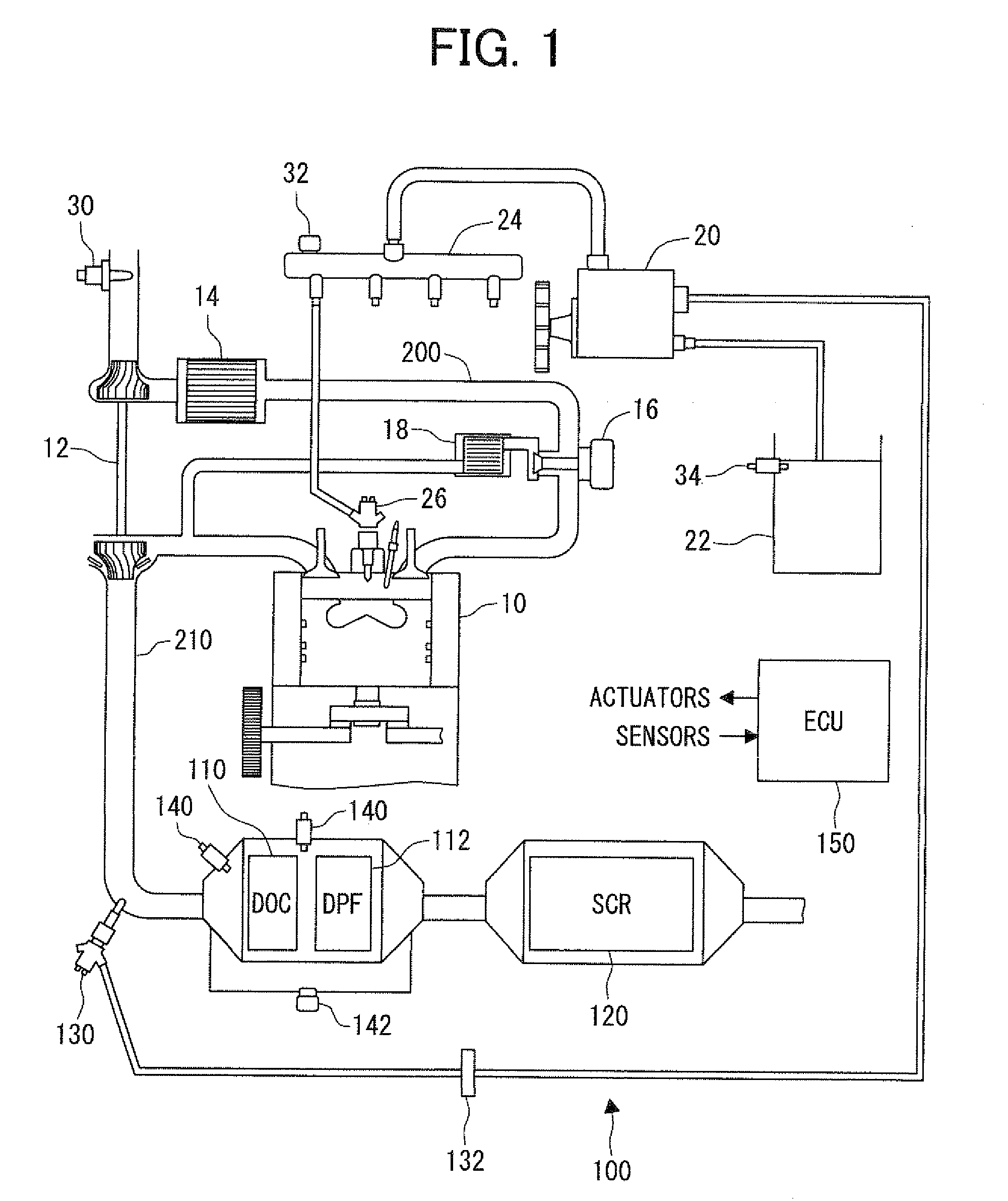

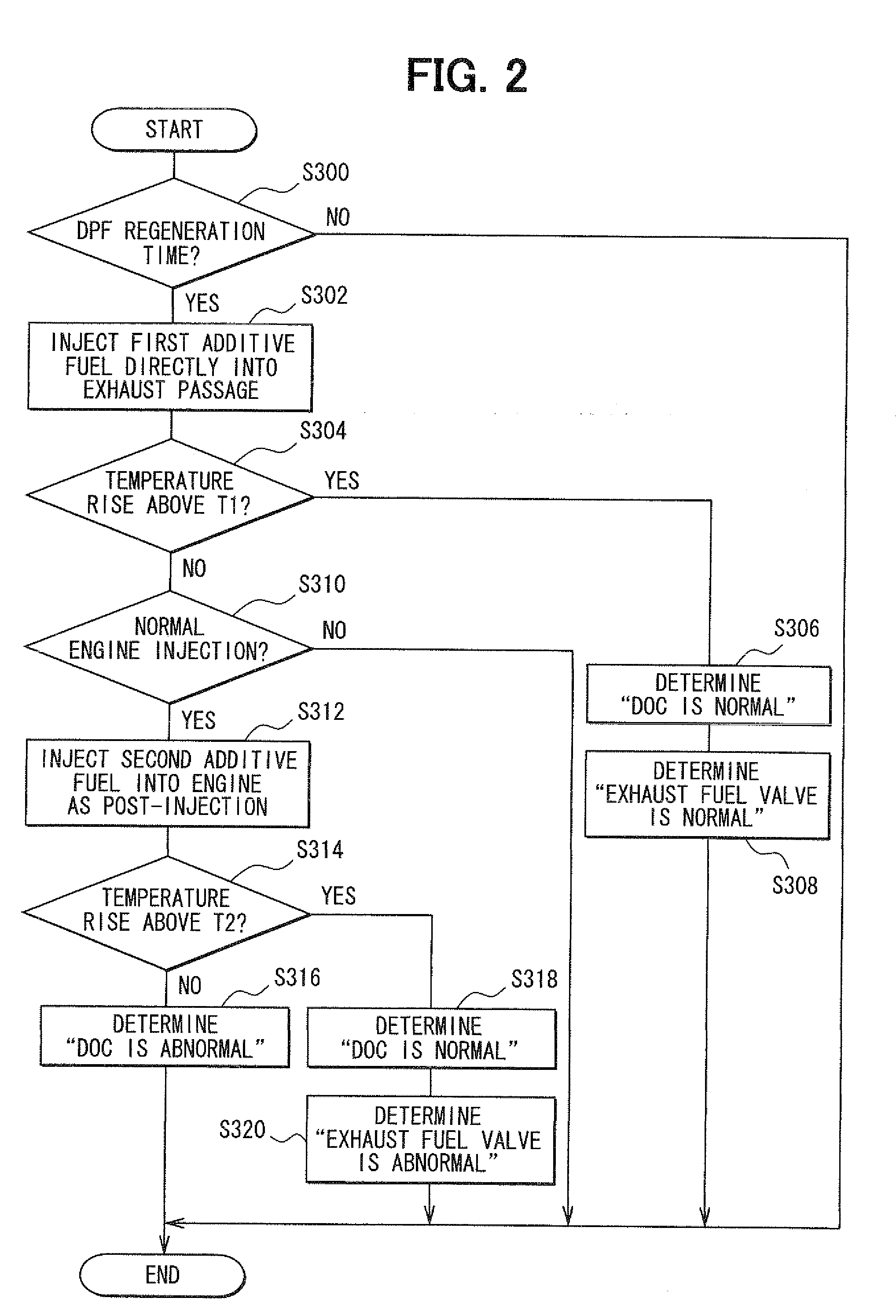

[0014]Referring first to FIG. 1, an exhaust purification system 100 is provided for purifying gas exhausted from a four-cylinder four-stroke diesel engine 10 into an exhaust passage 210.

[0015]The engine 10 has an intake passage 200, in which a turbocharger 12 is provided to supply compressed air and an intercooler 14 for cooling the compressed air before being supplied into the engine 10. The intake passage 200 and the exhaust passage 210 are connected to each other via an exhaust gas recirculation (EGR) passage, which recirculates a part of the exhaust gas of the engine 10 through an EGR cooler 18 and an EGR valve 16 when the EGR valve 16 is opened.

[0016]A fuel supply pump 20, which is a high-pressure pump having a reciprocating plunger, is provided to suction fuel from a fuel tank 22 and pressurize the fuel. The amount of pressurized fuel discharged or supplied from the fuel supply pump 20 is regulated by regulating the amount of fuel suctioned into the pump 20 by a metering valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com