Vehicle Barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

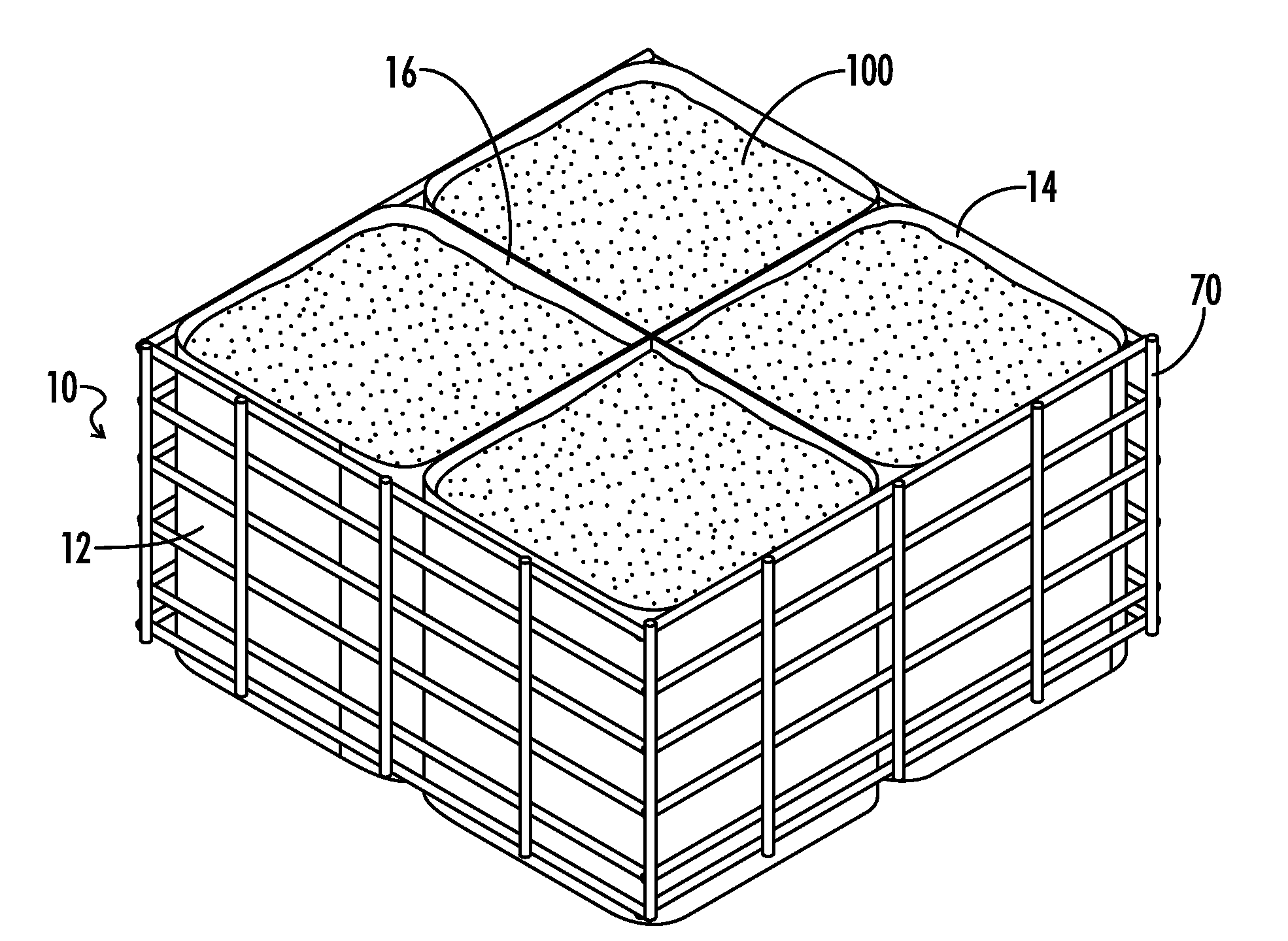

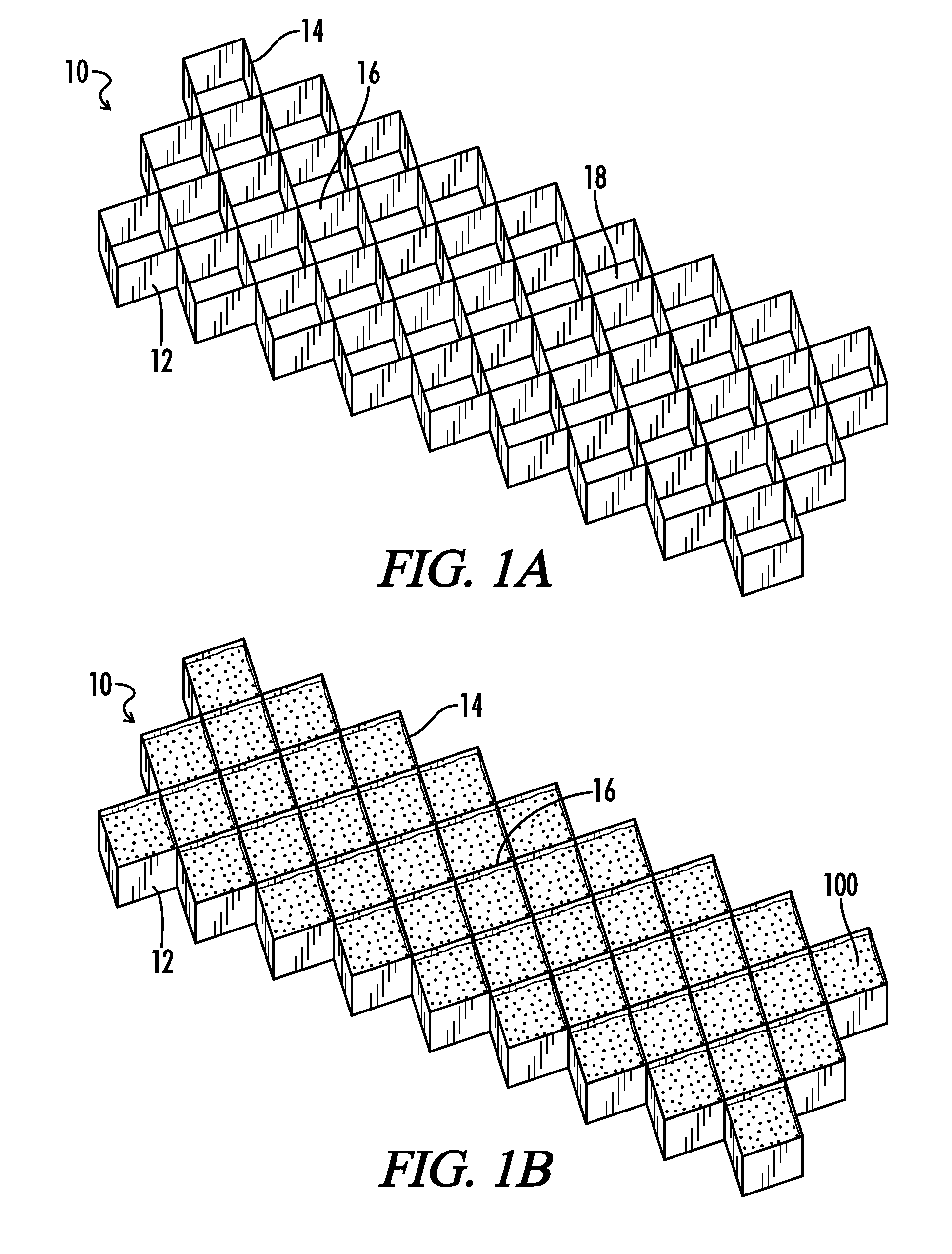

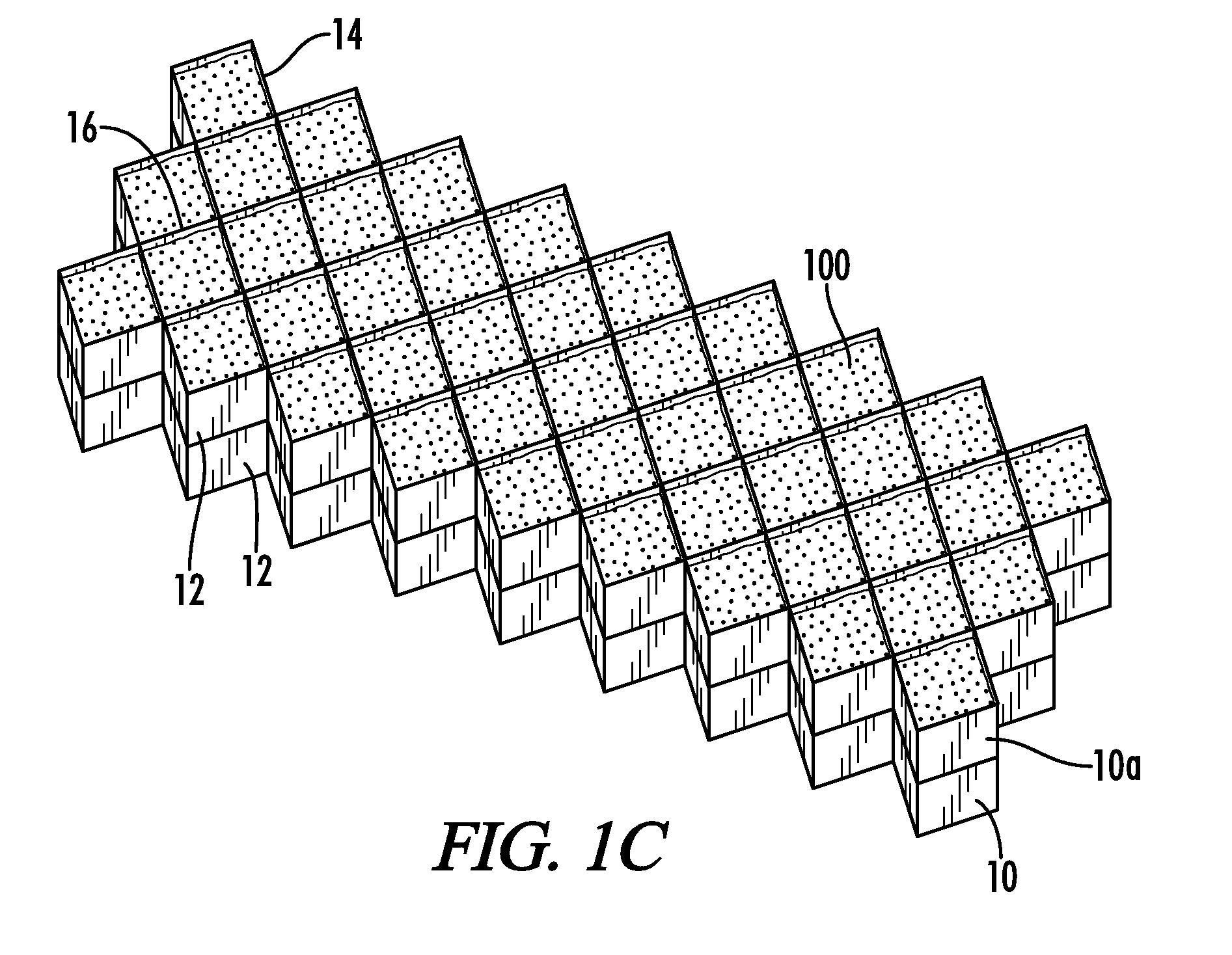

[0030]The present invention relates generally to vehicle barriers and more particularly to portable vehicle barriers. Referring now to the drawings (where, for ease of understanding, not all reference numerals are shown in all drawings), the present invention provides a barrier body 10 having an impact side 12 (i.e., the side of barrier body 10 facing the direction from which an impact is likely to occur), a reflection side 14, and a plurality of interior walls 16, as shown in FIG. 1A. The plurality of interior walls 16 extend between and join the impact side 12 and the reflection side 14. The plurality of interior walls 16, the impact side 12, and the reflection side 14 are arranged to form a plurality of hollow protection chambers 18 or plurality of vessels 18, which, in application, are filled with a fill material 100.

[0031]The vertical sides of the plurality of hollow protection chambers 18 are defined by either the plurality of interior walls 16 or some combination of the plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com