Rotating icemaker assembly

a rotating icemaker and assembly technology, which is applied in the field of refrigerator automatic icemaker assembly, can solve the problems of affecting the forming and harvesting of batch ice, the cost of the conventional icemaker assembly, and the undesirable noise of the conventional icemaker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

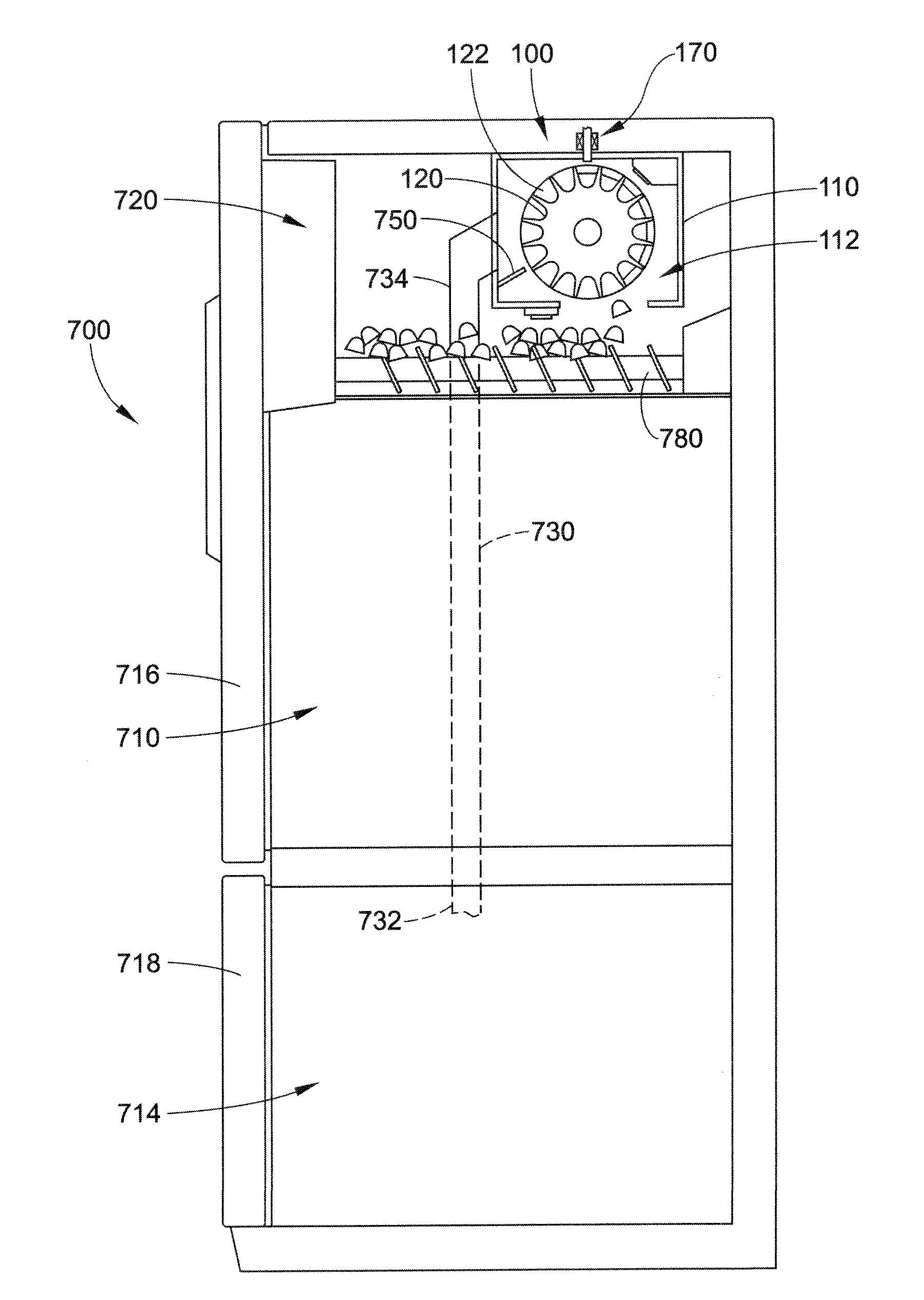

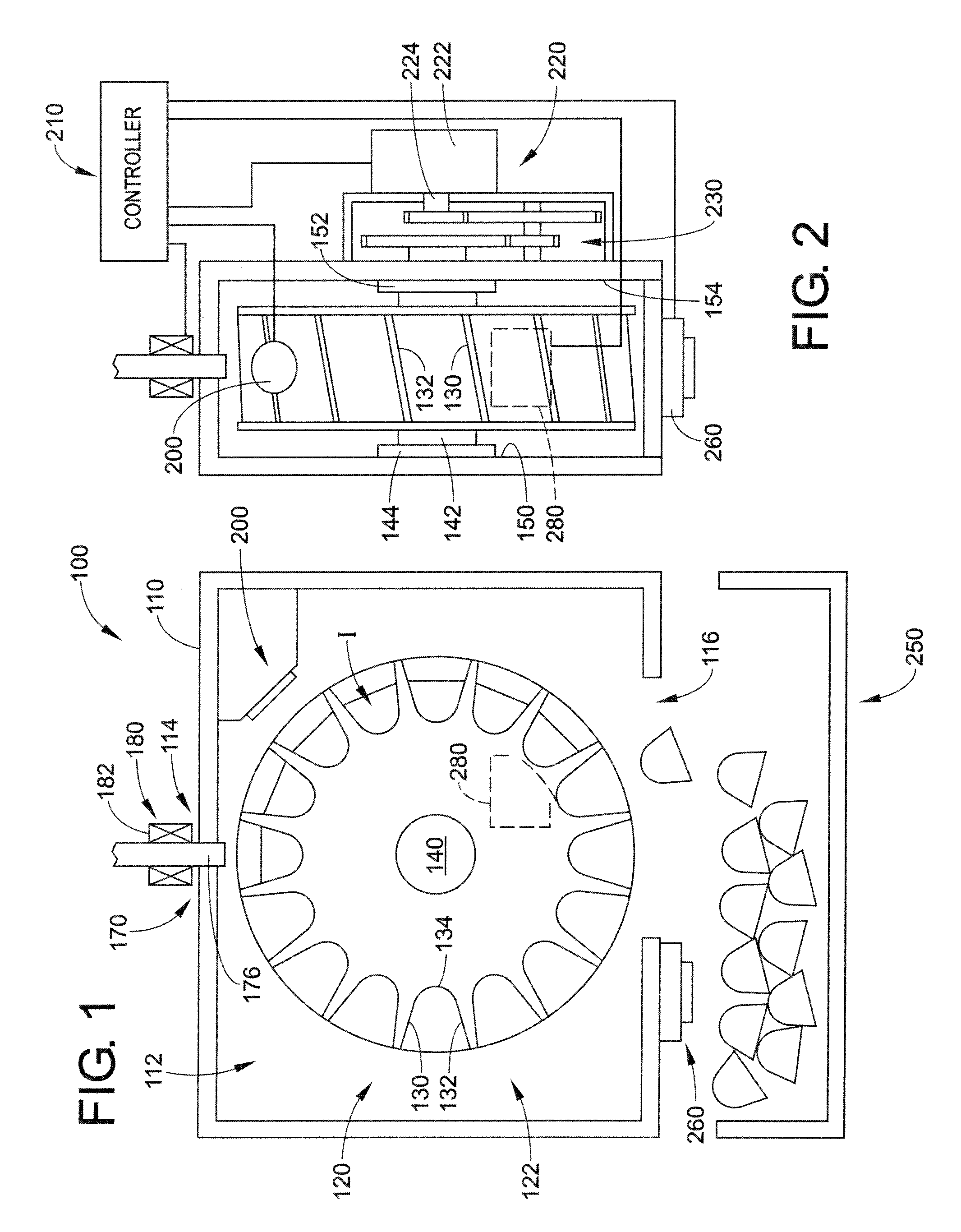

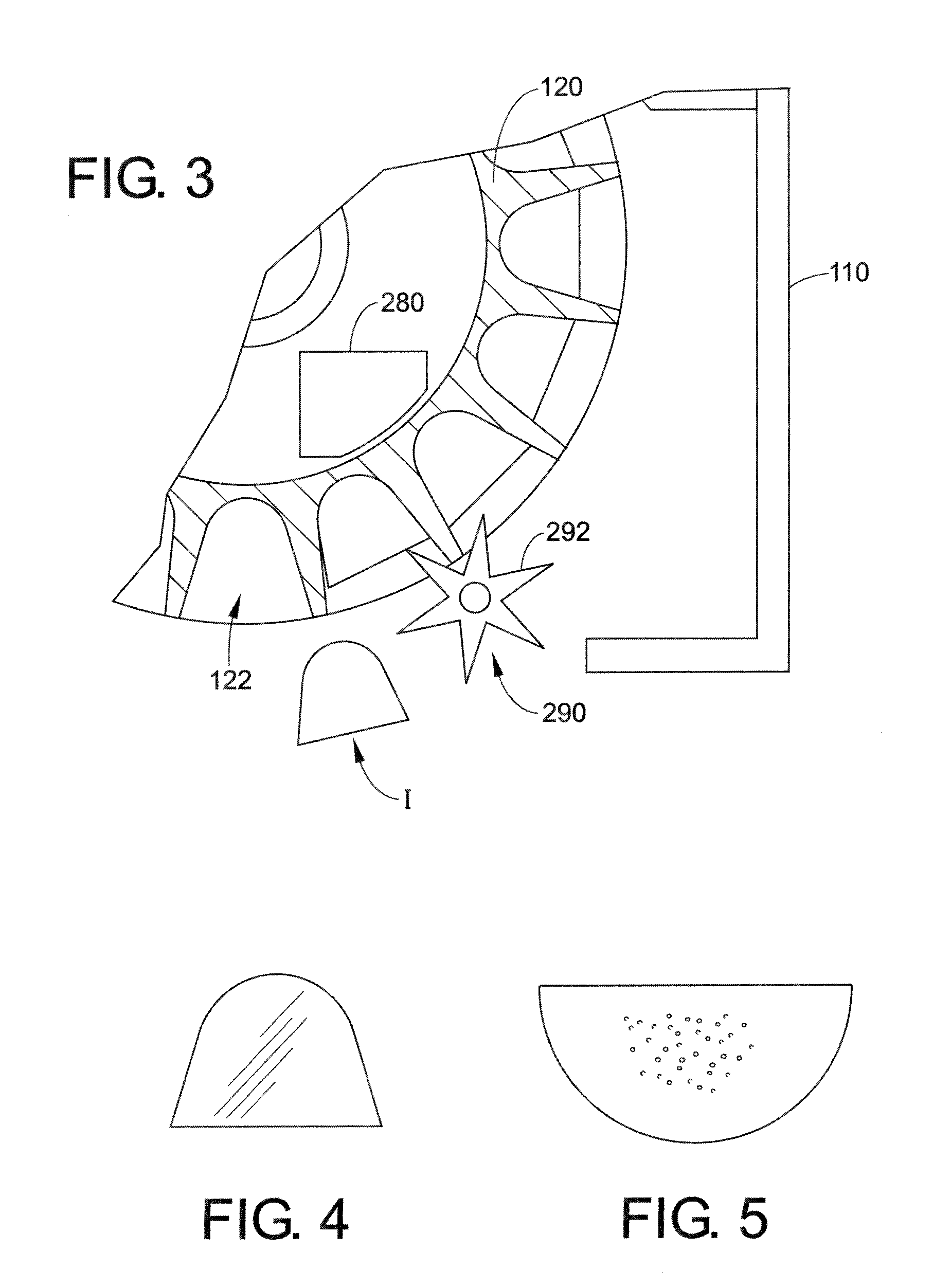

[0024]Referring now to the drawings, wherein like numerals refer to like parts throughout the several views, FIGS. 1 and 2 illustrate an icemaker assembly 100 for a refrigerator according to one aspect of the present disclosure. The icemaker assembly includes a housing 110. The housing defines a chamber 112 and includes a first opening 114 disposed at an upper portion of the housing and a second opening 116 disposed at a lower portion of the housing. An ice mold 120 is rotatably disposed within the chamber 112 of the housing 110 for continuously freezing water and continuously harvesting ice. The term continuous is used in this context to refer to an icemaker configuration in which each individual ice cube or pair of ice cubes is formed and harvested on its own time line, as contrasted with the conventional “batch” process hereinbefore mentioned in which all of the cube forming compartments in the mold are filled in a single fill operation and the ice cubes are formed and harvested ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com