Modular Low-Clearance Centralizer and Method of Making Modular Low-Clearance Centralizer

a low-clearance centralizer and modular technology, applied in the direction of drilling pipes, drilling casings, borehole/well accessories, etc., can solve the problems of high cost of low-clearance bow spring centralizers cut from a unitary piece of tubular, increase the manufacturing cost of the centralizer, and time-consuming alternative methods, etc., to achieve efficient and inexpensive, the effect of reducing cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

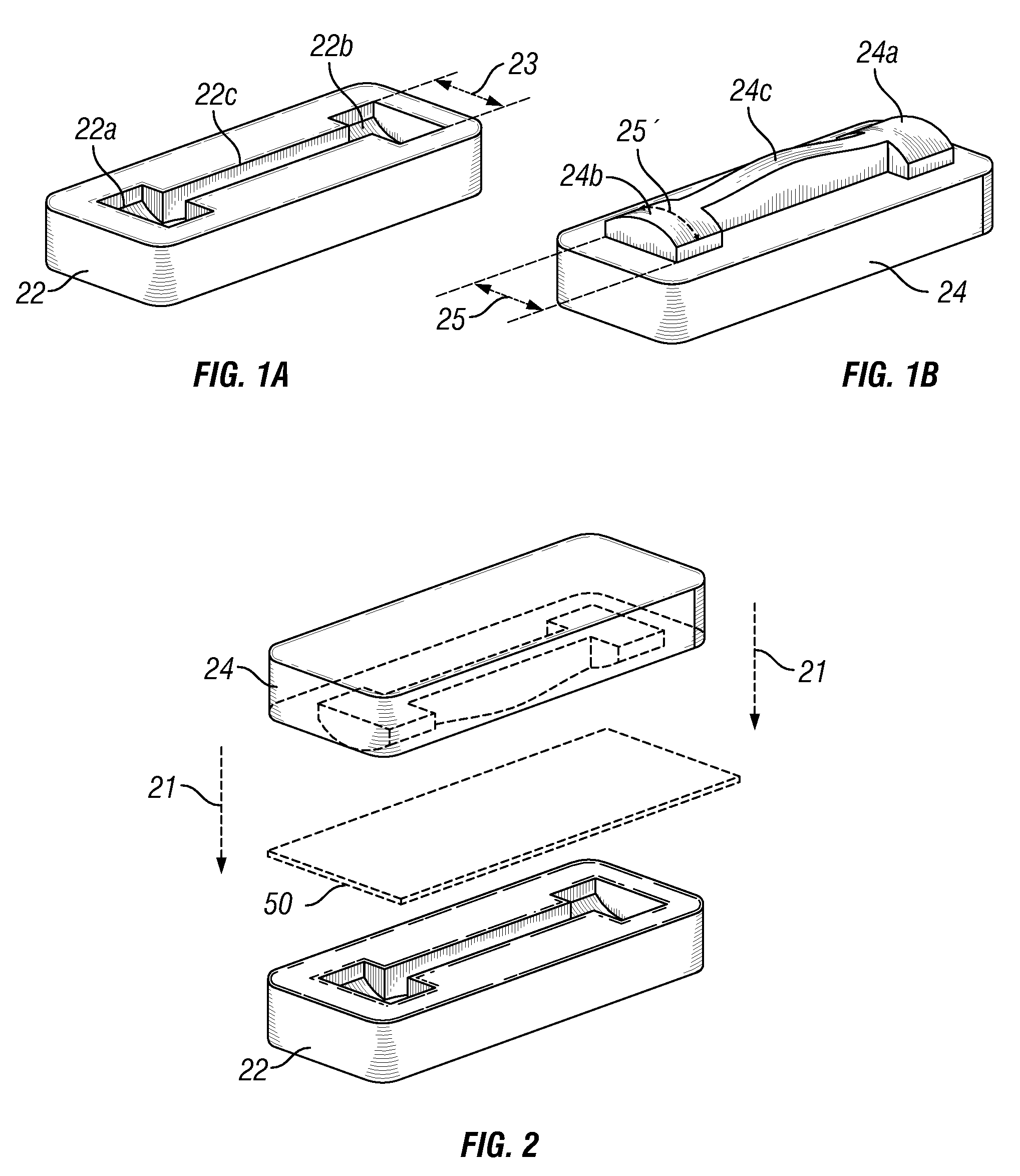

[0030]FIG. 1A is a perspective view of a female die cavity 22 that may be used to produce one embodiment of a bow spring module according to one embodiment of the invention. The die cavity of FIG. 1A comprises a first collar segment recess 22a, a second collar segment recess 22b, and a rib recess 22c connecting the first collar segment recess 22a to the second collar segment recess 22b. It should be understood that the first collar segment recess 22a and the second collar segment recess 22b may be generally identical, and each may comprise a uniformly curved bottom having a generally uniform radius of curvature, and the bottom may be recessed and / or surrounded by a generally vertical wall.

[0031]FIG. 1B is a perspective view of a male die 24 that may be used with the female die cavity of FIG. 1A to produce an embodiment of a bow spring module according to one embodiment of the invention. The male die 24 comprises a first collar segment protrusion 24a, a second collar segment protrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com