Fuel cell stack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

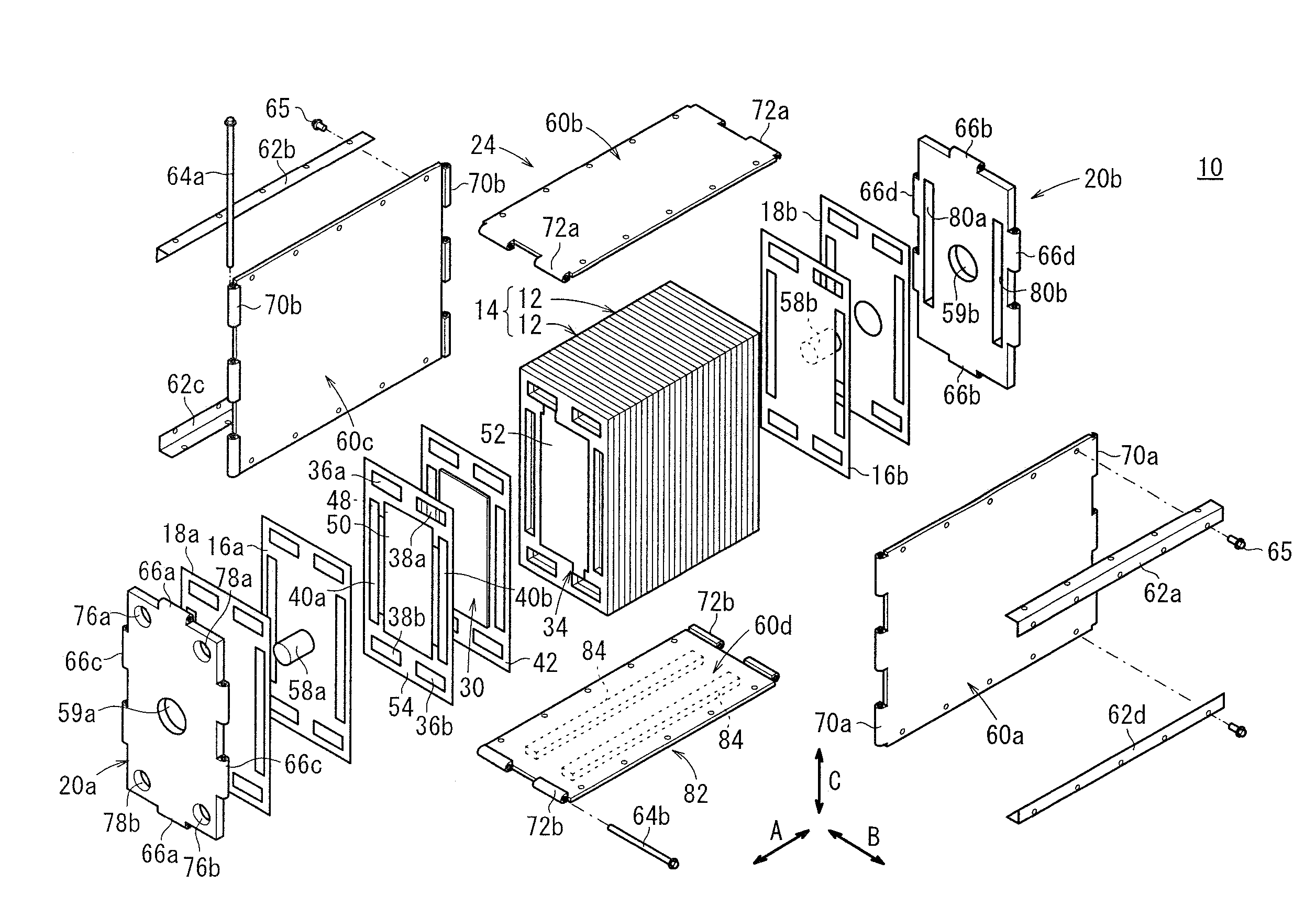

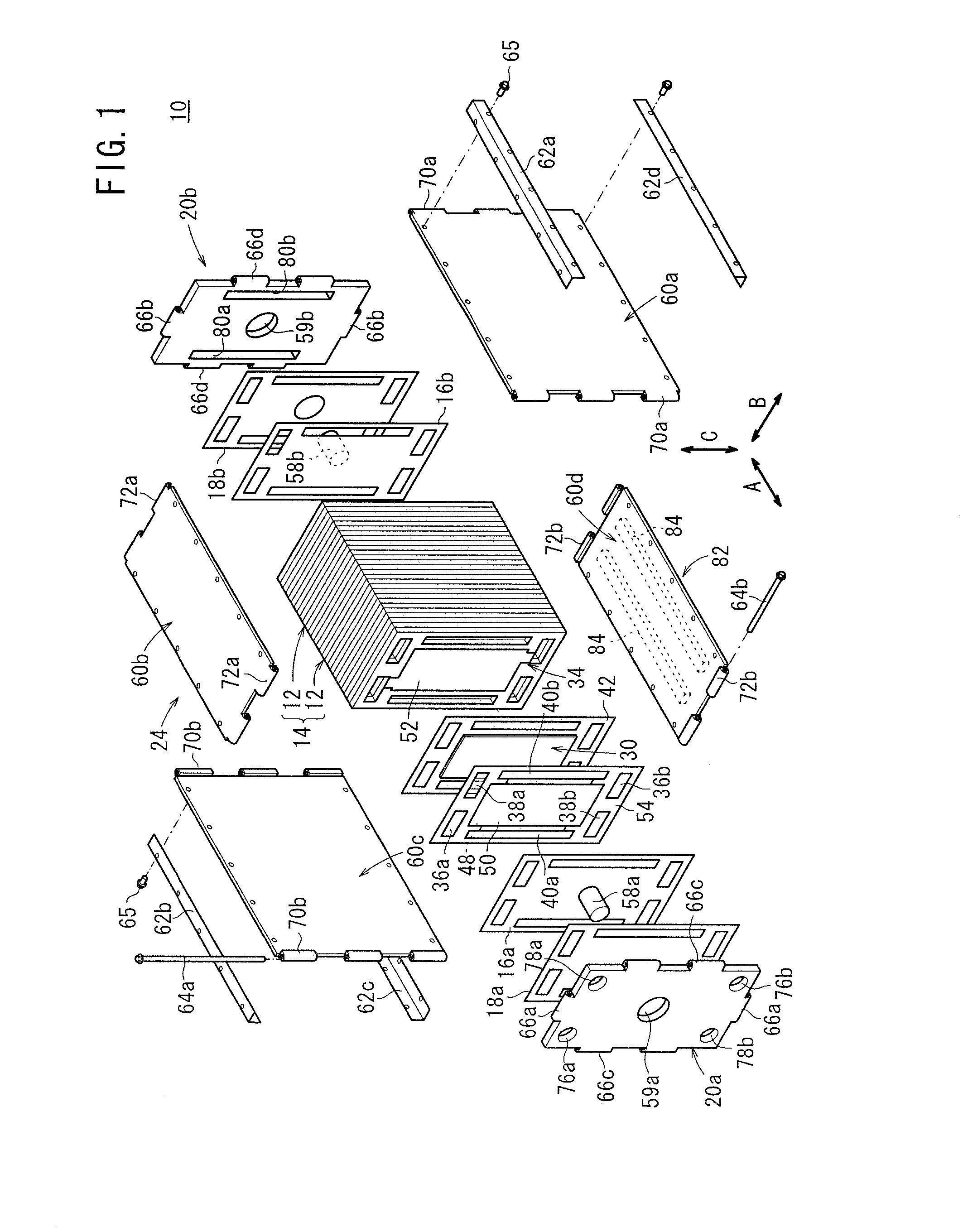

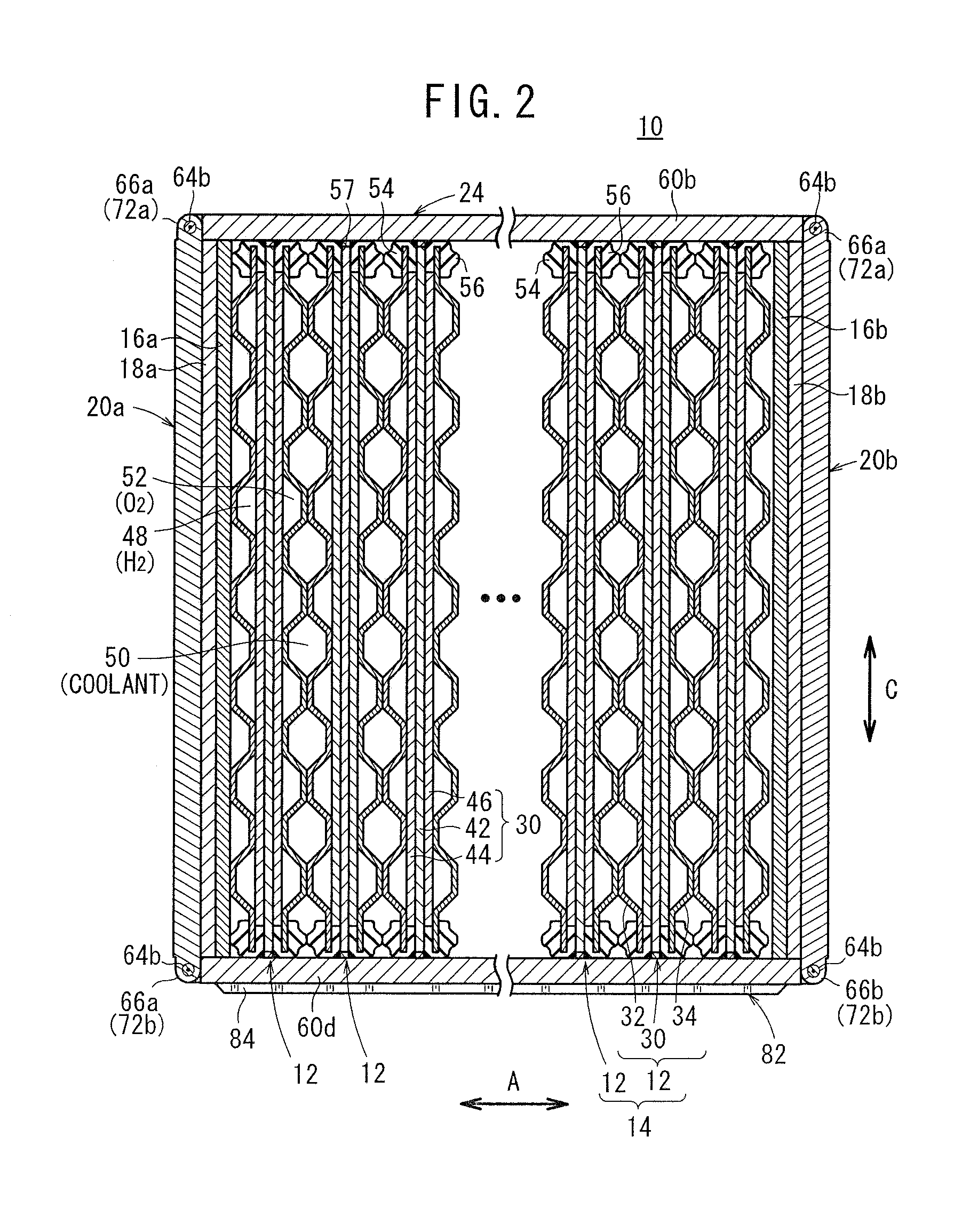

[0033]As shown in FIGS. 1 and 2, a fuel cell stack 10 according to the present invention includes a stack body 14 formed by stacking a plurality of unit cells 12 in a horizontal direction indicated by an arrow A. At one end of the stack body 14 in a stacking direction indicated by the arrow A, a terminal plate 16a is provided. An insulating plate 18a is provided outside the terminal plate 16a, and an end plate 20a is provided outside the insulating plate (insulator) 18a. At the other end of the stack body 14 in the stacking direction, a terminal plate 16b is provided. An insulating plate 18b (insulator) is provided outside the terminal plate 16b, and an end plate 20b is provided outside the insulating plate 18b. An insulating spacer member may be used as the insulating plate 18b. The fuel cell stack 10 is placed in a box-shaped casing 24 including the rectangular and vertically elongate end plates 20a, 20b.

[0034]As shown in FIGS. 2 and 3, each of the unit cells 12 is formed by sand...

third embodiment

[0071]FIG. 6 is a partial cross sectional view showing a fuel cell stack 100 according to the present invention.

[0072]In the fuel cell stack 100, each of the unit cells 12 has stack deformation prevention structure 102. The stack deformation prevention structure 102 is configured such that elastic modulus of ends 54a, 56a on the upper side of the first and second seal members 54, 56 in the direction of gravity is higher than elastic modulus of ends 54b, 56b on the lower side of the first and second seal members 54, 56 in the direction of gravity. Specifically, cross sectional areas of the first and second seal members 54, 56 or materials of the first and second seal members 54, 56 are changed for changing the elastic modulus.

[0073]In the third embodiment, elastic modulus of the ends 54a, 56a on the upper side of the first and second seal members 54, 56 in the direction of gravity is higher than elastic modulus of the ends 54b, 56b on the lower side of the first and second seal membe...

fourth embodiment

[0075]FIG. 7 is a side view showing a unit cell 12 of a fuel cell stack 110 according to the present invention.

[0076]In the fuel cell stack 110, each of the unit cells 12 has stack deformation prevention structure 112. The stack deformation prevention structure 112 is configured such that the thickness (t1) on the lower side of the first and second metal separators 32, 34 in the direction of gravity is smaller than the thickness (t2) on the upper side of the first and second metal separators 32, 34 in the direction of gravity (t12).

[0077]In the fourth embodiment, in each of unit cells 12, deformation in the stacking direction occurs easily on the lower side in the direction of gravity, in comparison with the upper side in the direction of gravity. It is because the thickness (t1) on the lower side of the first and second metal separators 32, 34 is smaller than the thickness (t2) on the upper side of the first and second metal separators 32, 34. Therefore, when the lower side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com