Fan filter unit

a filter unit and fan technology, applied in the direction of positive displacement liquid engines, lighting and heating apparatus, heating types, etc., can solve the problems of inability to adjust the rotating speed of the motor, poor capability, and whining sound, so as to suppress the whining sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first exemplary embodiment

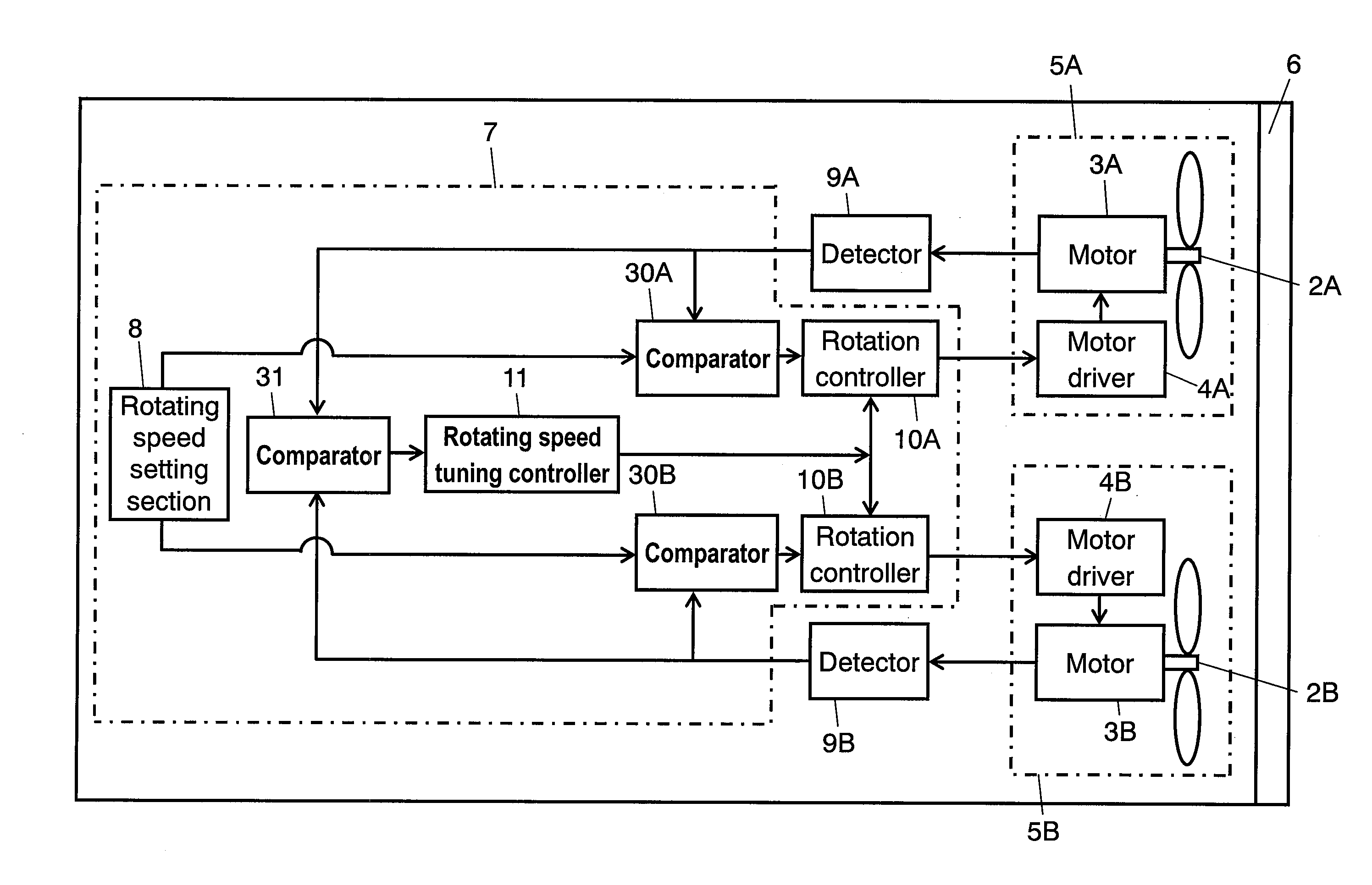

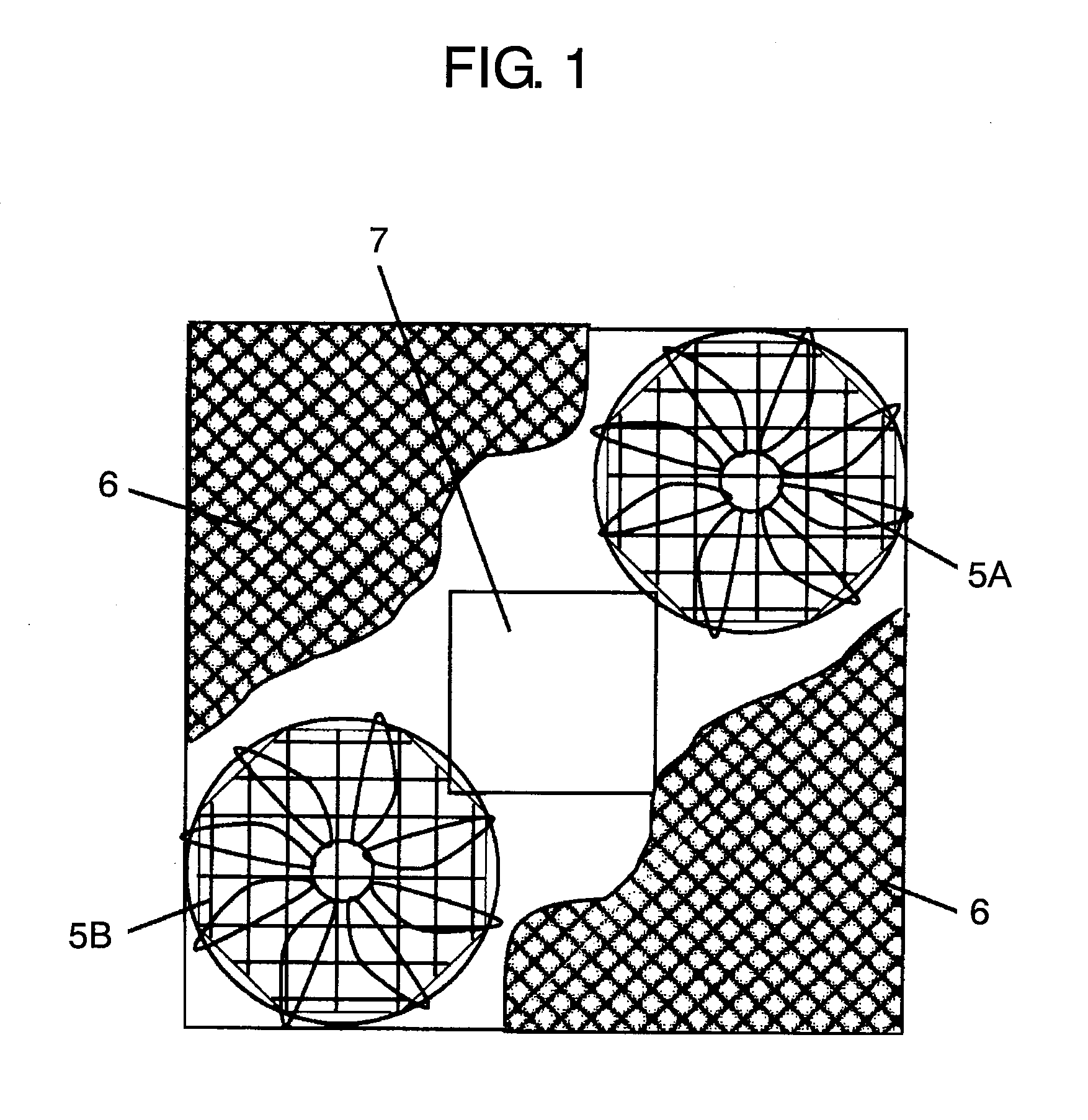

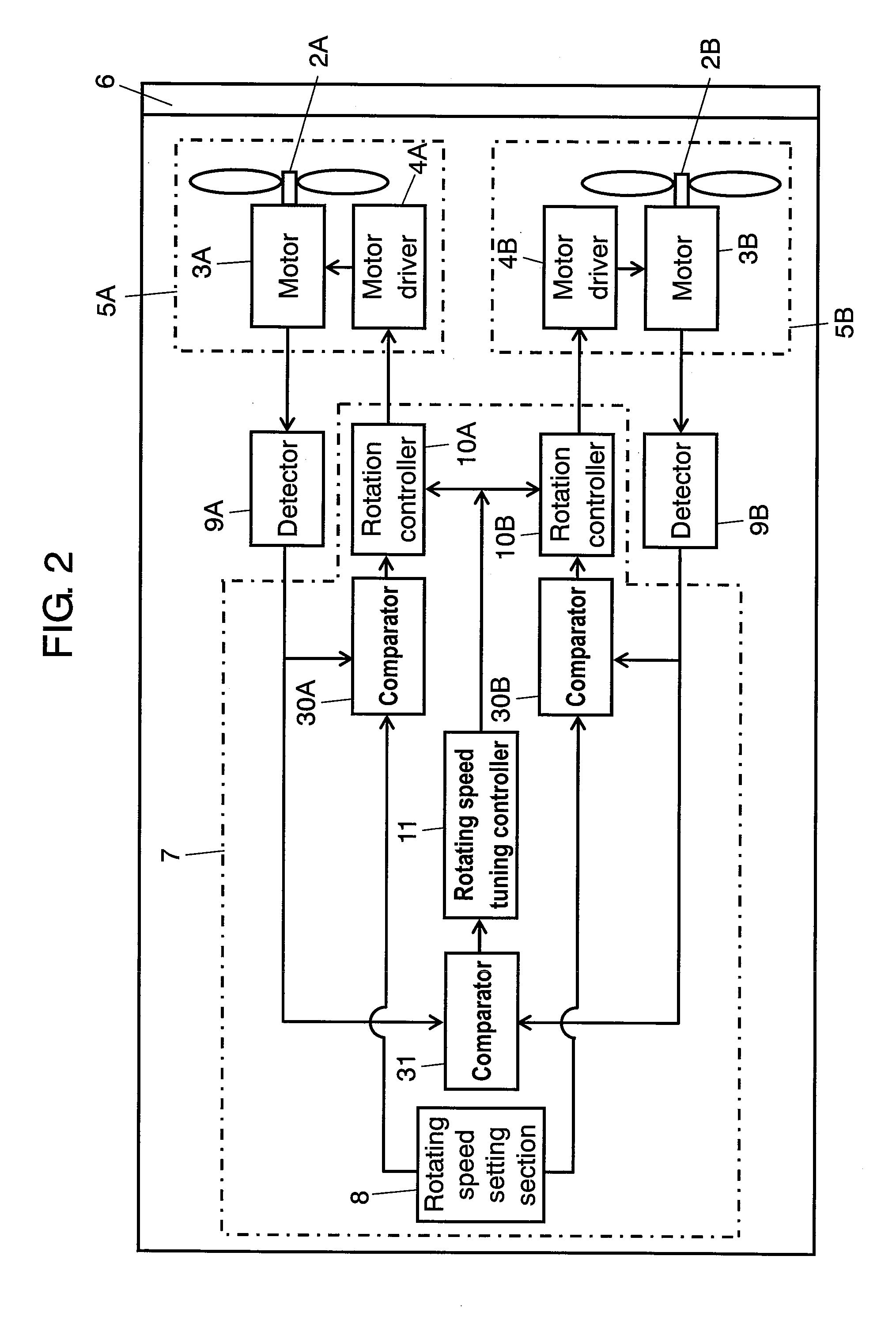

[0015]FIG. 1 illustrates a schematic structure of a fan filter unit according to a first exemplary embodiment of the present invention. FIG. 1 is a front view in which the filter is partially cut out. FIG. 2 is a block circuit diagram thereof. This fan filter unit has first fan motor 5A, second fan motor 5B, and filter 6. Fan motor 5A is composed of first fan 2A, first motor 3A, and first motor driver 4A. Fan motor 5B is composed of second fan 2B, second motor 3B, and second motor driver 4B. Filter 6 cleans air blown by fans 2A and 2B. Filter 6 has glass fibers, for example, and captures micron-order fine particles with a high efficiency. More specifically, filter 6 traps fine particles of 0.3 μm with a trapping efficiency of 99.97% or more. Filter 6 is provided at the blowing side or suction side of fans 2A and 2B.

[0016]Fan filter unit has: total controller 7 (hereinafter referred to as controller 7) configure to control fan motors 5A and 5B; first detector 9A configured to detect ...

second exemplary embodiment

[0026]FIG. 3 is a block circuit diagram illustrating a fan filter unit according to a second exemplary embodiment of the present invention. This exemplary embodiment has the same structure as that of the first exemplary embodiment except for that total controller 73 is structured so that stabilizer 16 is provided between comparator 31 and rotation speed tuning controller 11 (hereinafter referred to as controller 11).

[0027]Stabilizer 16 is designed to prevent controller 11 from functioning until a preparatory operation performed for a predetermined time is completed. Stabilizer 16 prevents controller 11 from functioning in a time zone in which detected rotating speeds of fan motors 5A and 5B are unstable e.g., at a time just after the start of the operation of fan motors 5A and 5B or in a case where the rotating speeds change instantaneously. Stabilizer 16 is also composed by a microcomputer, for example.

[0028]Specifically, when a set rotating speed is 2000 r / min. for example, and de...

third exemplary embodiment

[0031]FIG. 4 is a block circuit diagram illustrating a fan filter unit according to a third exemplary embodiment of the present invention. This exemplary embodiment has the same structure as that of the first exemplary embodiment except for that total controller 74 includes retry section 19. Retry section 19 is also composed of a microcomputer, for example.

[0032]Retry section 19 has a retry function to try to provide a control by which the rotation speeds of fans 2A and 2B are adjusted to a rotating speed set by rotating speed setting section 8, when rotating speed tuning controller 11 (hereinafter referred to as controller 11) continuously performs a tuning control of rotating speed for a predetermined time.

[0033]When fan motors 5A and 5B are stopped during an important process in a clean room using the fan filter unit, the process may have a remarkably-deteriorated productivity. If fan motors 5A and 5B are operated with a low rotating speed, an expected air volume provided by a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com