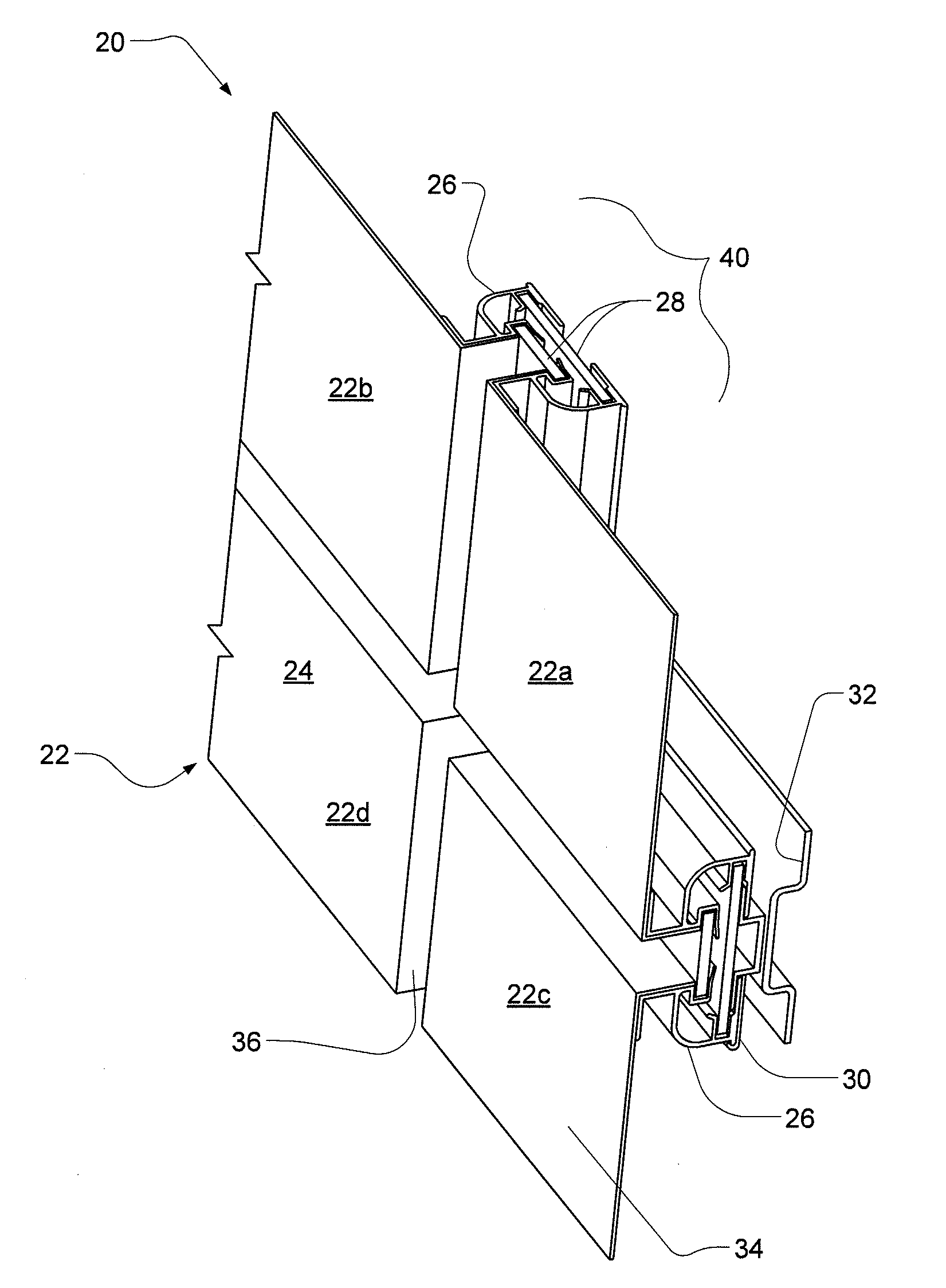

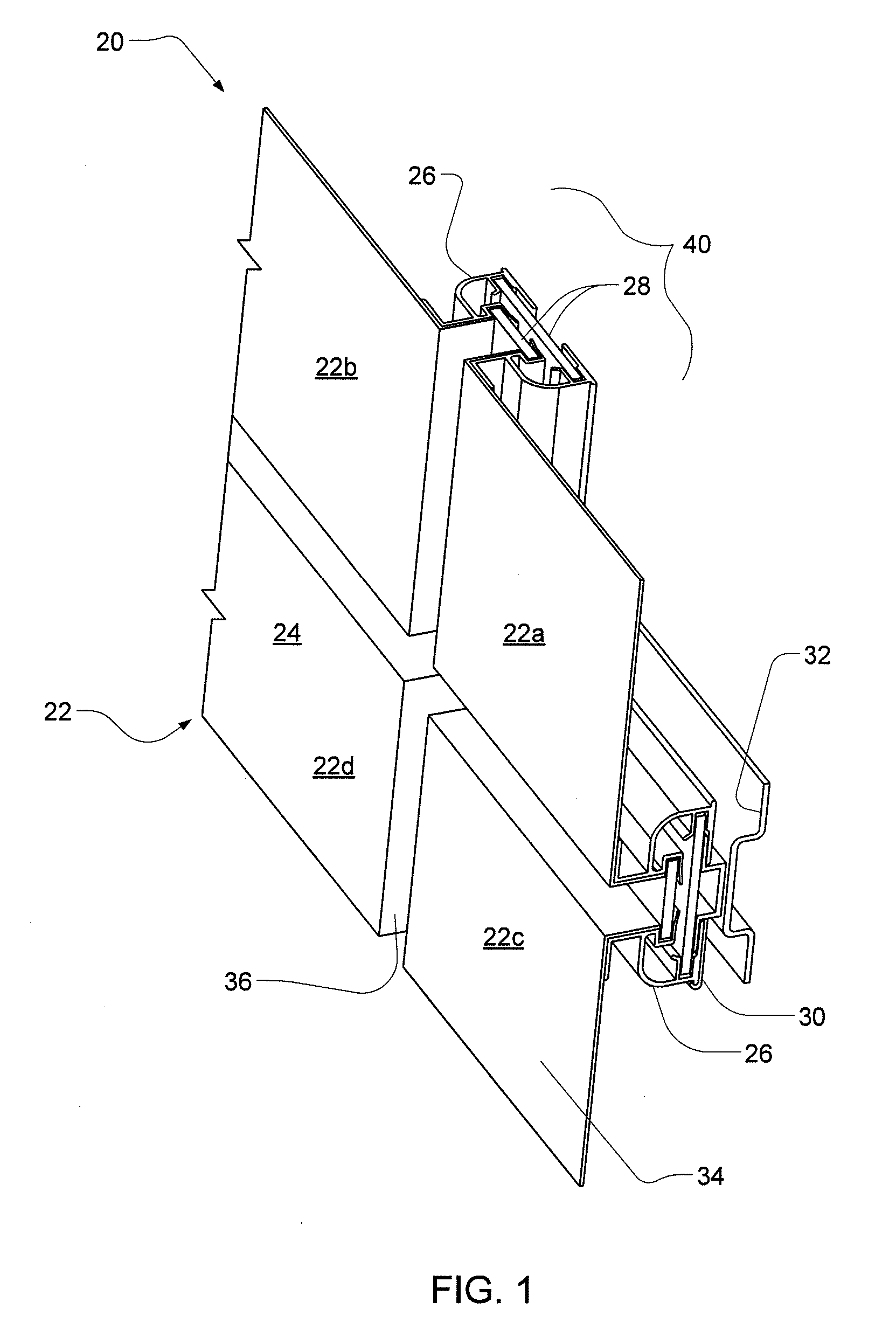

Wall panel joint apparatus and system using same

a wall panel joint and wall panel technology, applied in the field of wall panel joints and systems, can solve problems such as system problems, water damage, water damage, and/or lack of venting capability, and achieve the effect of optimizing ventilation and minimizing water entry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

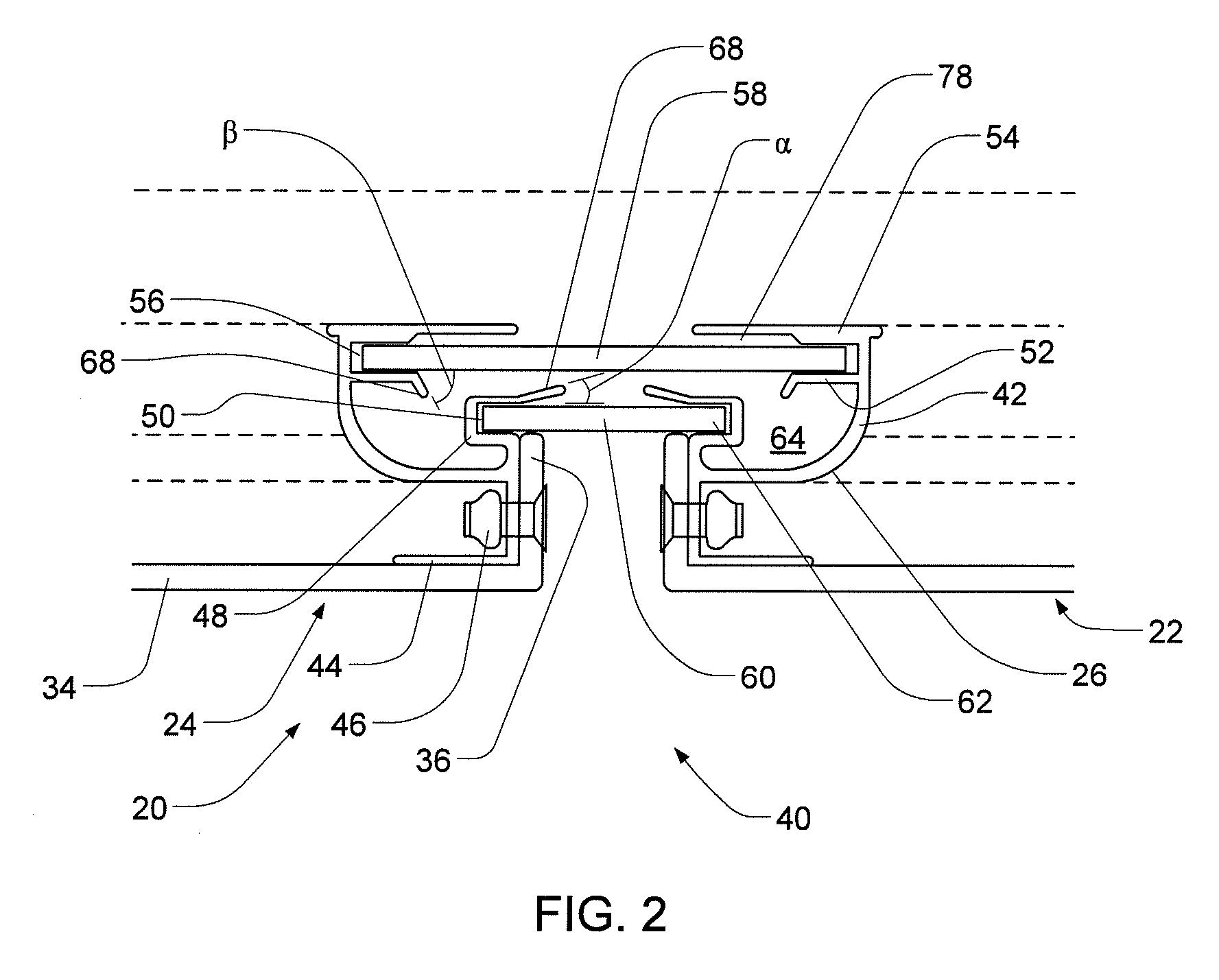

[0081]Referring again to FIGS. 2 and 3, the features in this exemplary embodiment of the horizontal and vertical joints work to prevent water from penetrating into the architectural wall. This is proven by the tests represented in the examples below.

[0082]Air infiltration, water penetration, and structural performance tests of the system installed in a laboratory test chamber were performed. Wall Assembly A was tested on Apr. 8, 2005; Wall Assembly B was tested for water penetration in accordance with ASTM: E 331 on Apr. 22, 2005, and for water penetration in accordance with ASTM: E 331 but modified to monitor air flow as openings were cut in the back-up wall on May 6 and Jun. 7, 2005. The following comments describe the test procedures and results for each wall assembly.

DESCRIPTIONS OF WALL ASSEMBLIES

[0083]WALL ASSEMBLY A—APR. 8, 2005: water penetration air infiltration and structural tests were performed on Wall Assembly A.

[0084]TEST SPECIMEN—DESCRIPTION

[0085]The following wall as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com