Minimally-thick orthopedic prosthesis is disclosed which closely matches the end of a bone of a joint after that bone end has been minimally reshaped and resurfaced by an orbital or lineally oscillating orthopedic resurfacing tool in the minimally invasive orthopedic surgical repair or reconstruction of hip, knee, ankle, shoulder, elbow, wrist, and other joints

a technology of orthopedic prosthesis and bone end, which is applied in the field of minimally-thick orthopedic prosthesis, can solve the problems of secondary surgical repair procedures, blood clots and heart attacks, and may be difficult to achieve, and achieve the effects of less time in surgery and less cost of surgical procedures, and more uniform and satisfactory recovery from surgery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

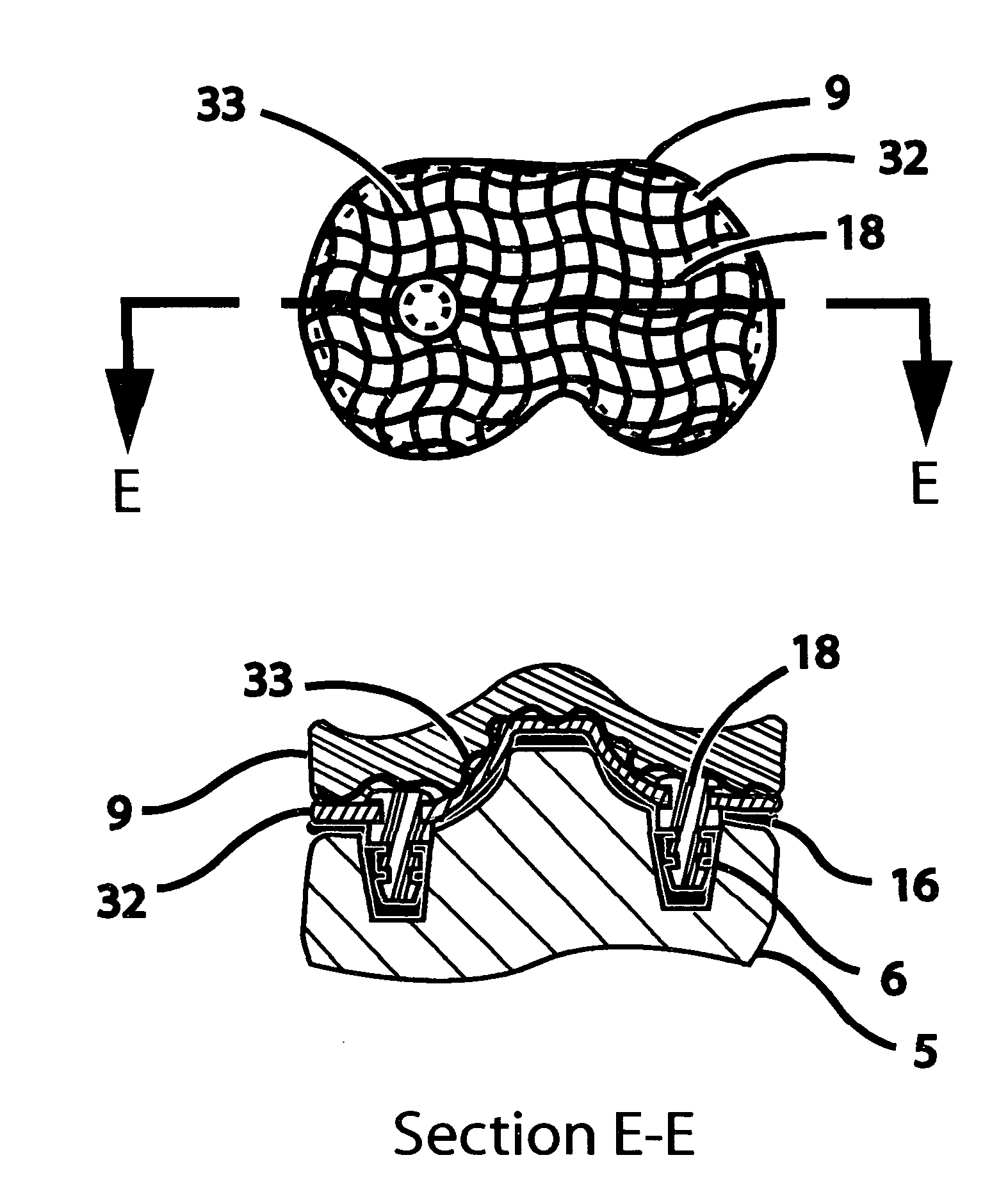

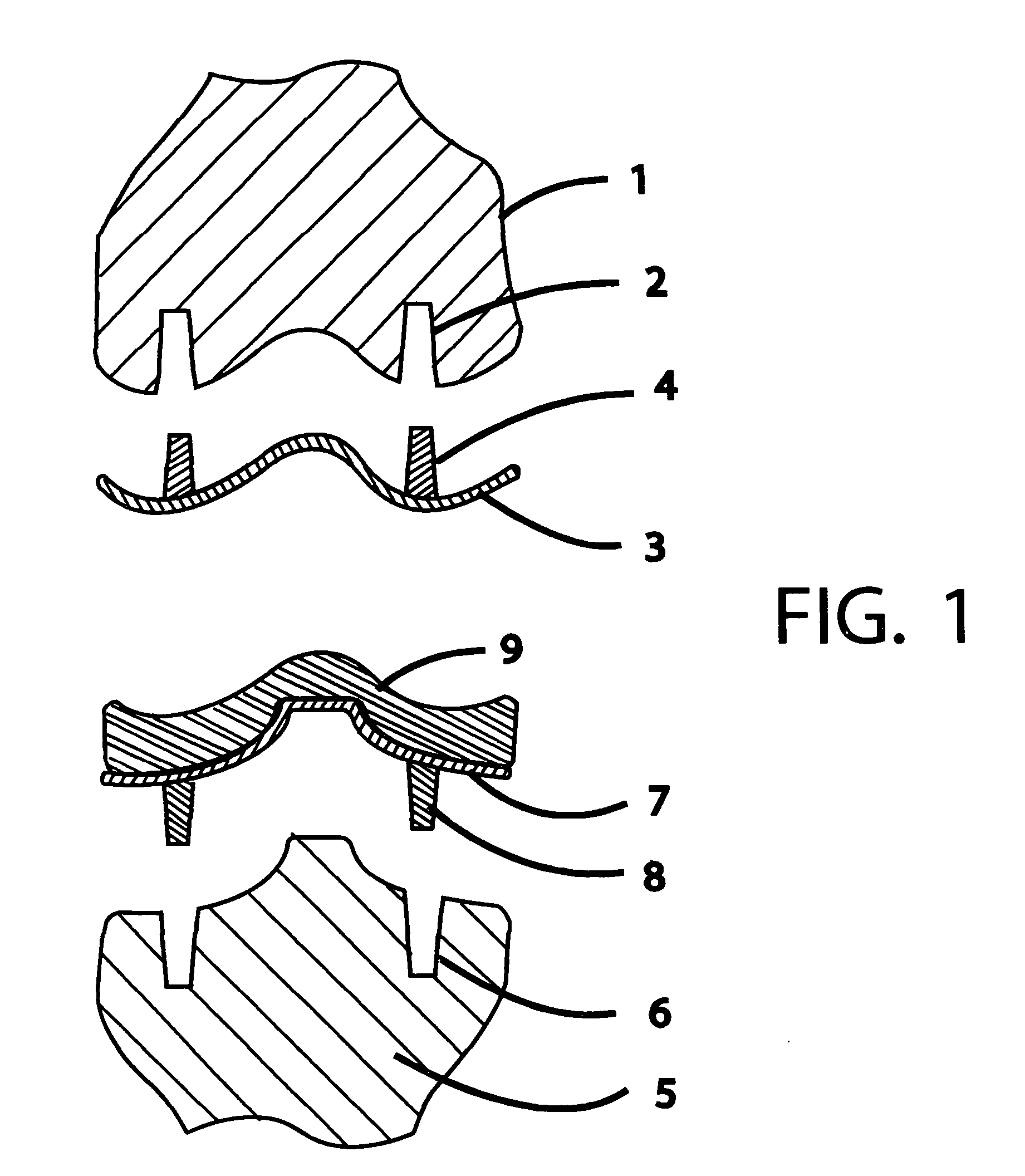

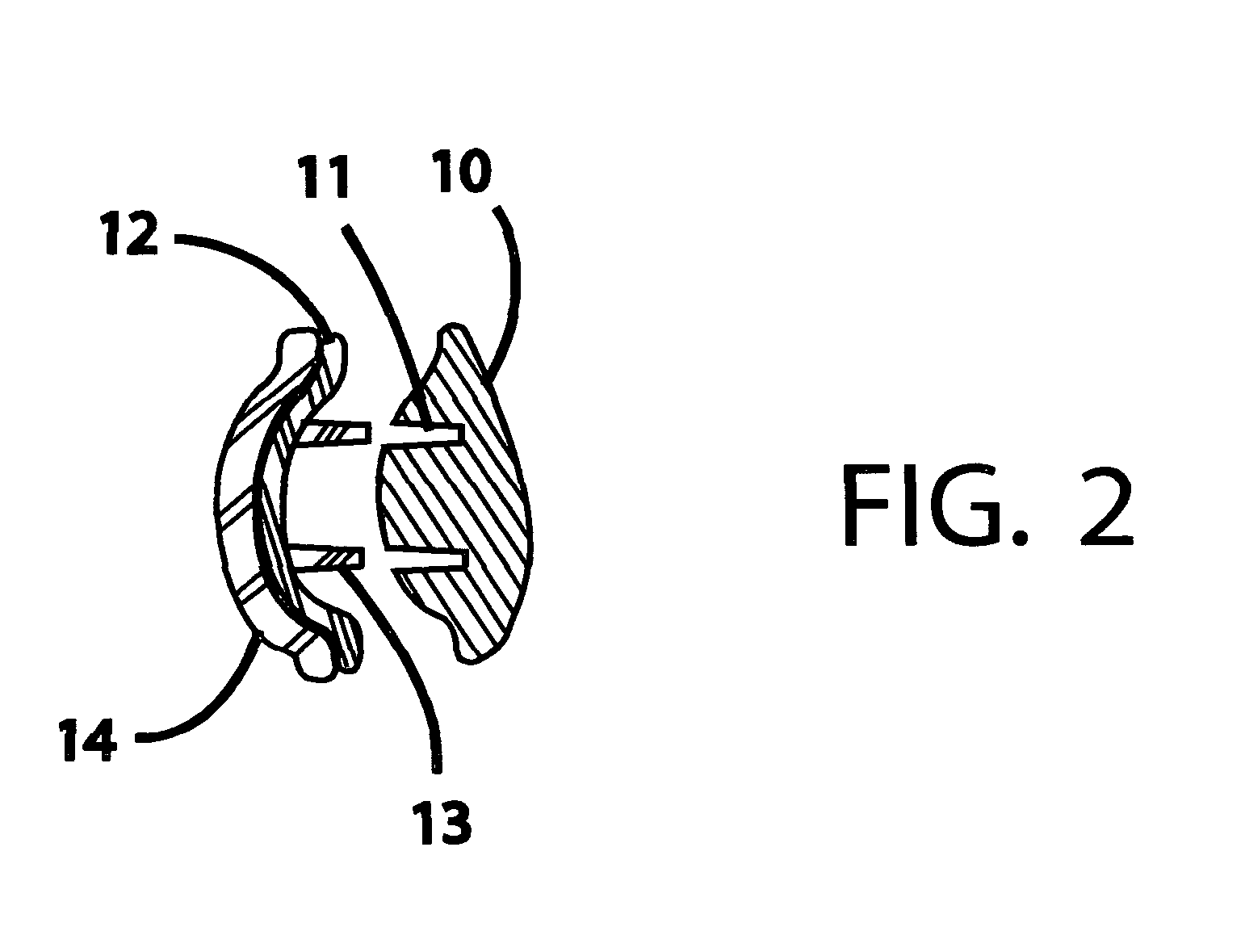

[0023]In the orthopedic surgical repair or reconstruction of the hip, knee, ankle, shoulder, elbow, wrist, or other joint, an orbital or lineally oscillating orthopedic resurfacing tool is used which has a cutting head so configured as to match an average typical shape of the surface of a particular bone end. A minimally-thick orthopedic prosthesis is formed which closely matches the surface of the orthopedic resurfacing tool's cutting head and therefore closely matches the surface of the bone end resurfaced by that cutting head. Because patient's are of different sizes, several sizes of cutting heads and surface-matching minimally-thick orthopedic prostheses may be required for each bone end of each joint. This unique matched-surface relationship between the resurfaced bone end and its surface-matching minimally-thick orthopedic prostheses provides the bone end with a minimally-thick new wear surface and retains the patient's original tendon tensions and varus and valgus bone align...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com