Controlled Collapse Bottle

a bottle and control technology, applied in the field of squeezeable containers, can solve the problems of not allowing air to enter the bottle, collapse would work its way up the bottle, etc., and achieve the effects of increasing shelf life and sanitation, convenient use, and being convenient to manufacture and packag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

. EMBODIMENTS

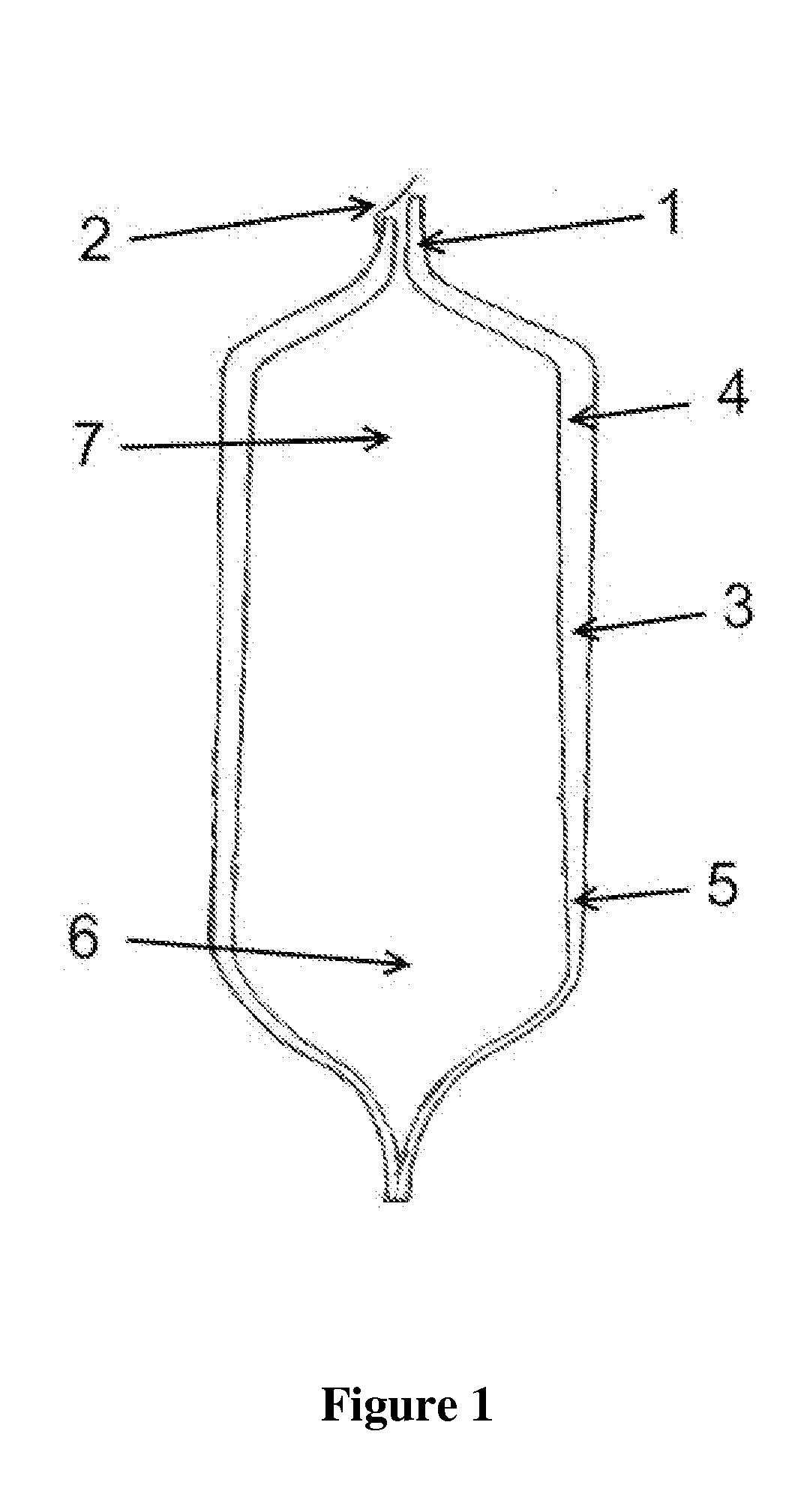

[0024]The invention is a container that has a nozzle (1) with a one-way valve (2). This nozzle allows liquid to be dispensed from the bottle but forbids the entry of air into the bottle (3).

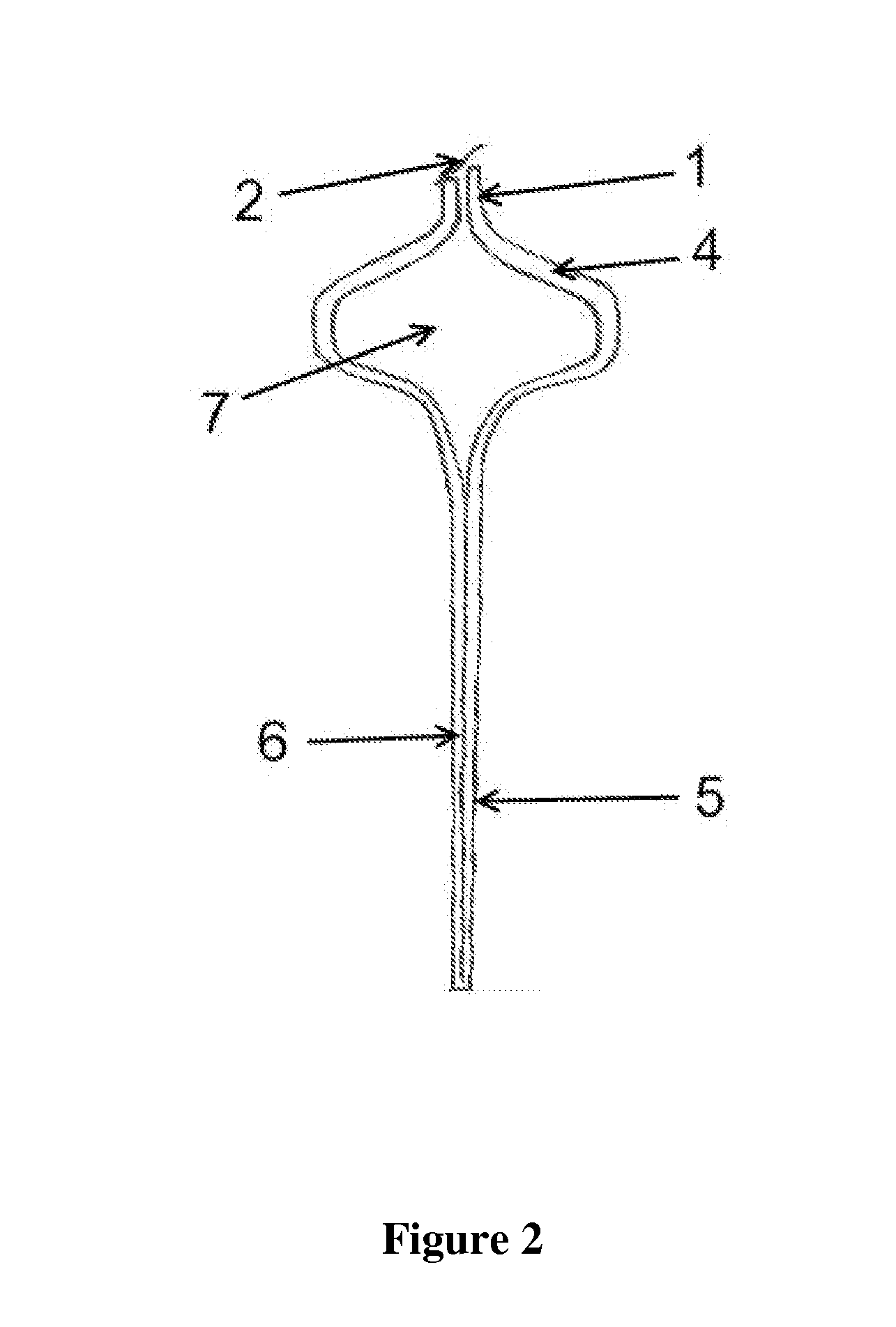

[0025]The walls of the bottle (3) are of varying thickness. Walls that are thicker (4) are closer to the nozzle. Walls that are thinner (5) are more remote from the nozzle. Since no air can enter the bottle, it will collapse when liquid is dispensed (see FIGS. 2, 4, and 6). The area more remote from the nozzle (6) will collapse first because the walls of that area are thinner (5). The area nearer the nozzle (7) will collapse last because the walls of that area are thicker (4).

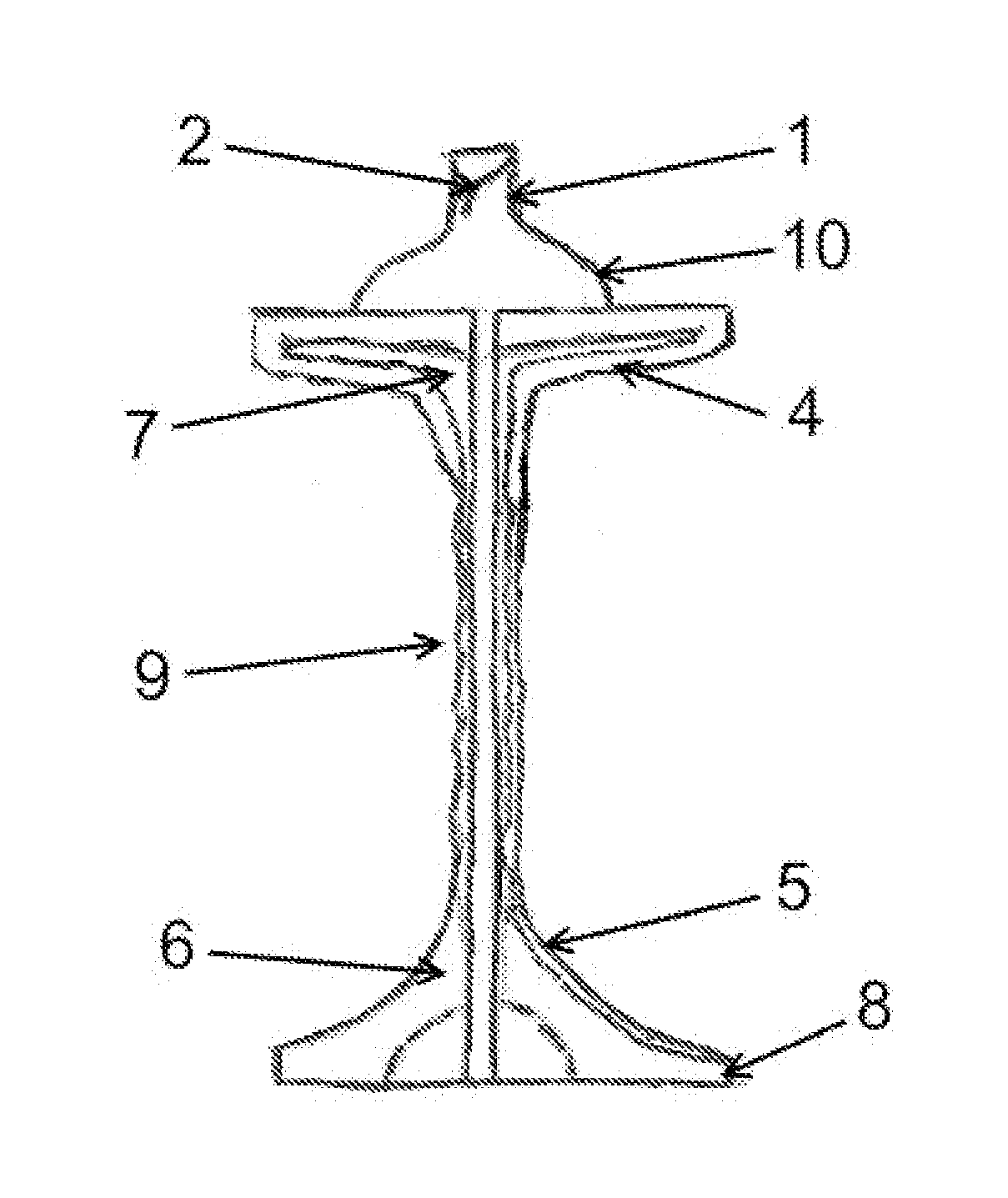

[0026]FIGS. 3, 4, 5, and 6 show an embodiment that is capable of standing upright throughout the life of the bottle. This embodiment has a top cap (10) wherein the nozzle is set. This embodiment also incorporates the nozzle (1), one-way valve (2), thin walls remote from the nozzle (5), and thick walls near the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com