Rear door heat exchanger transition frame

a heat exchanger and transition frame technology, applied in the direction of heat transfer modification, electrical equipment, lighting and heating apparatus, etc., can solve the problems of over-crowding of servers, over-crowding of cooling components, and exceeding the needs and budget of start-ups and cost-sensitive operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 300

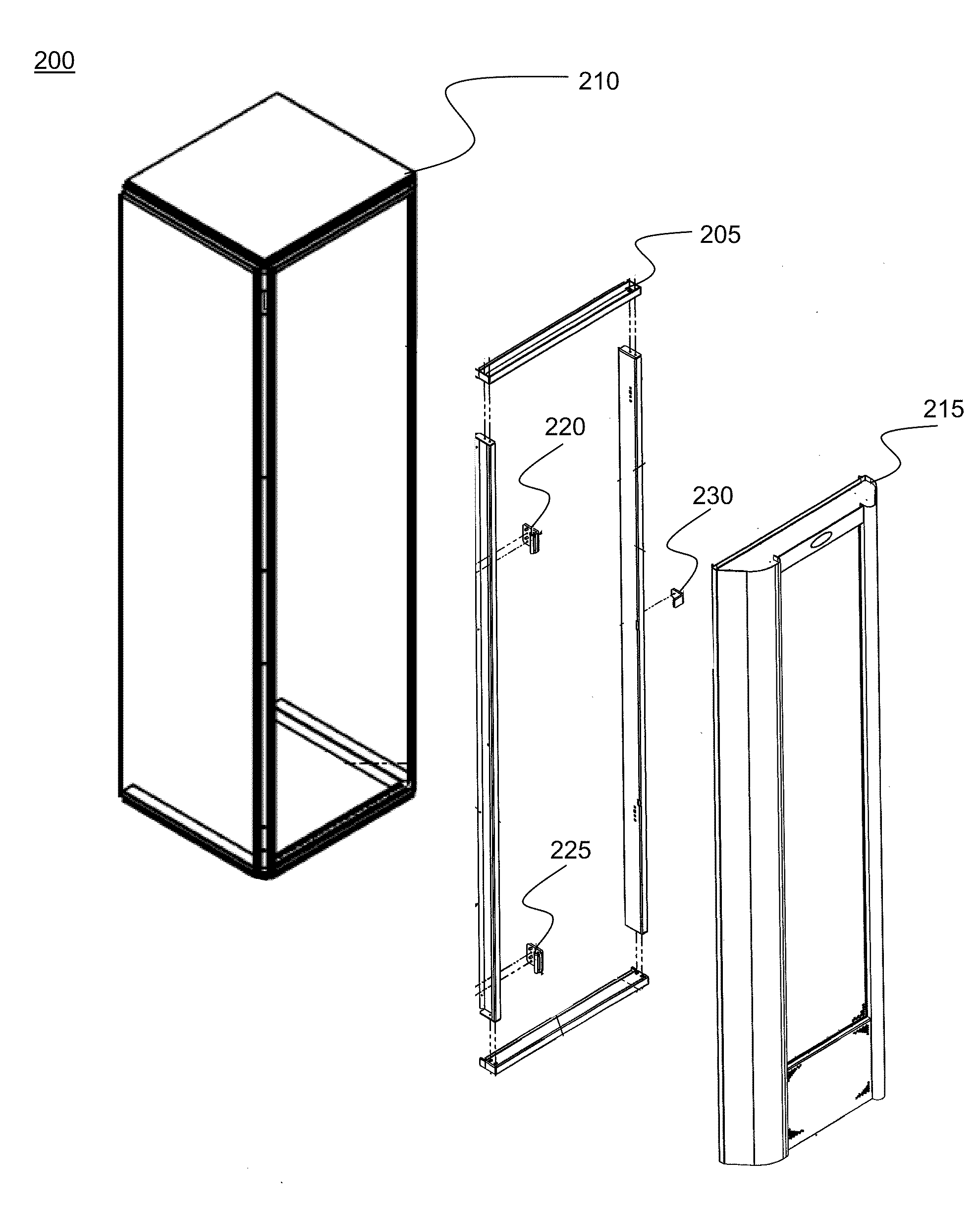

[0040]FIG. 3 is a diagram of components comprising a first transition frame embodiment 300 depicting vertical side 305 and cross section A-A 310 of vertical side 305. Second view 315 of vertical side depicts view B-B of section 310. Perspective view of horizontal side 320 is also shown in orthogonal view C-C 325.

embodiment 400

[0041]FIG. 4 is a diagram of components comprising a second transition frame embodiment 400 depicting vertical side 405 and cross section A-A 410 of vertical side 405. Second view 415 of vertical side depicts view B-B of section 410. Perspective view of horizontal side 420 is also shown in orthogonal view C-C 425.

embodiment 500

[0042]FIG. 5 is a diagram of components comprising a third transition frame embodiment 500 depicting vertical side 505 and cross section A-A 510 of vertical side 505. Second view 515 of vertical side depicts view B-B of section 510. Perspective view of horizontal side 520 is also shown in orthogonal view C-C 525.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com