Multi-Use Punch

a multi-use, punch technology, applied in the field of punches, can solve the problem that the conventional punch (60/b>) cannot be used as a different tool, and achieve the effect of improving convenience and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

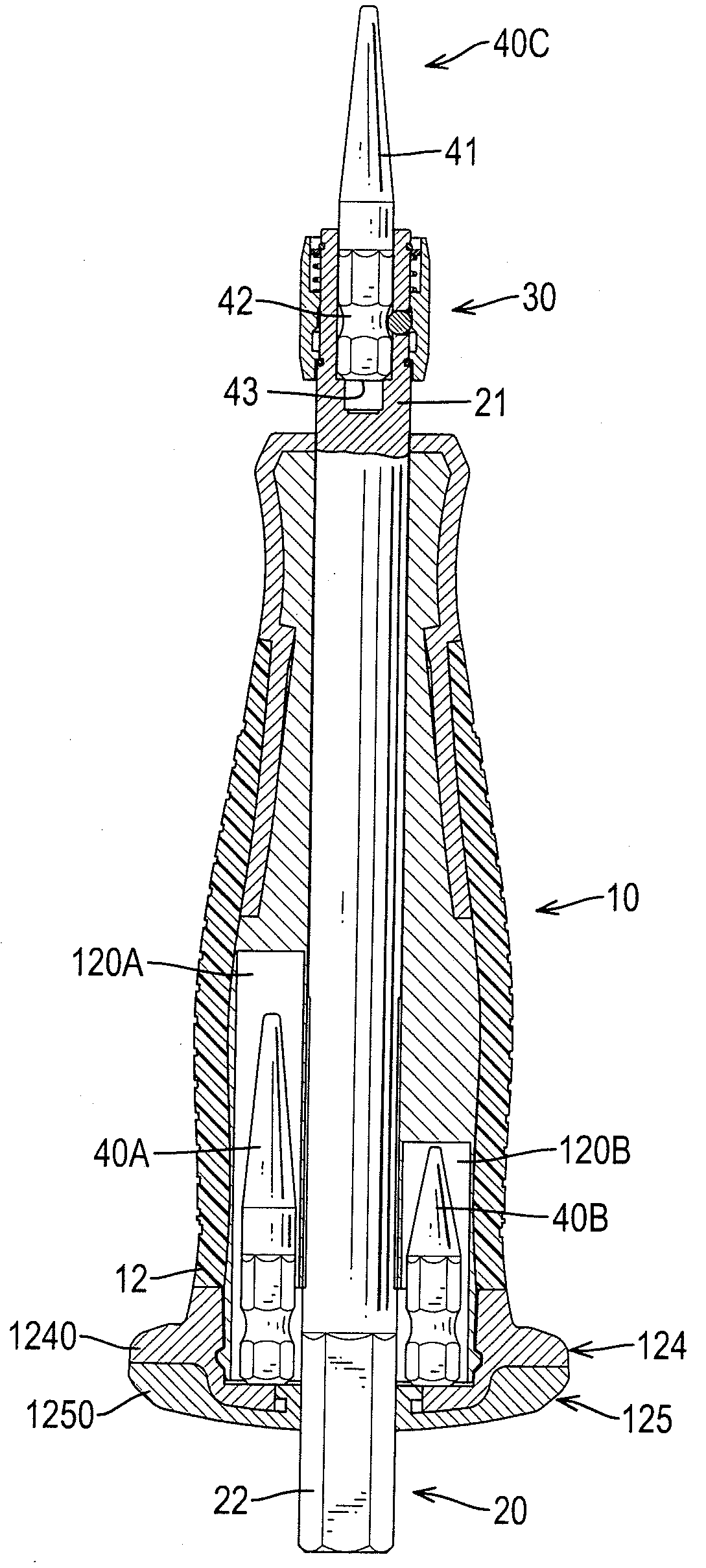

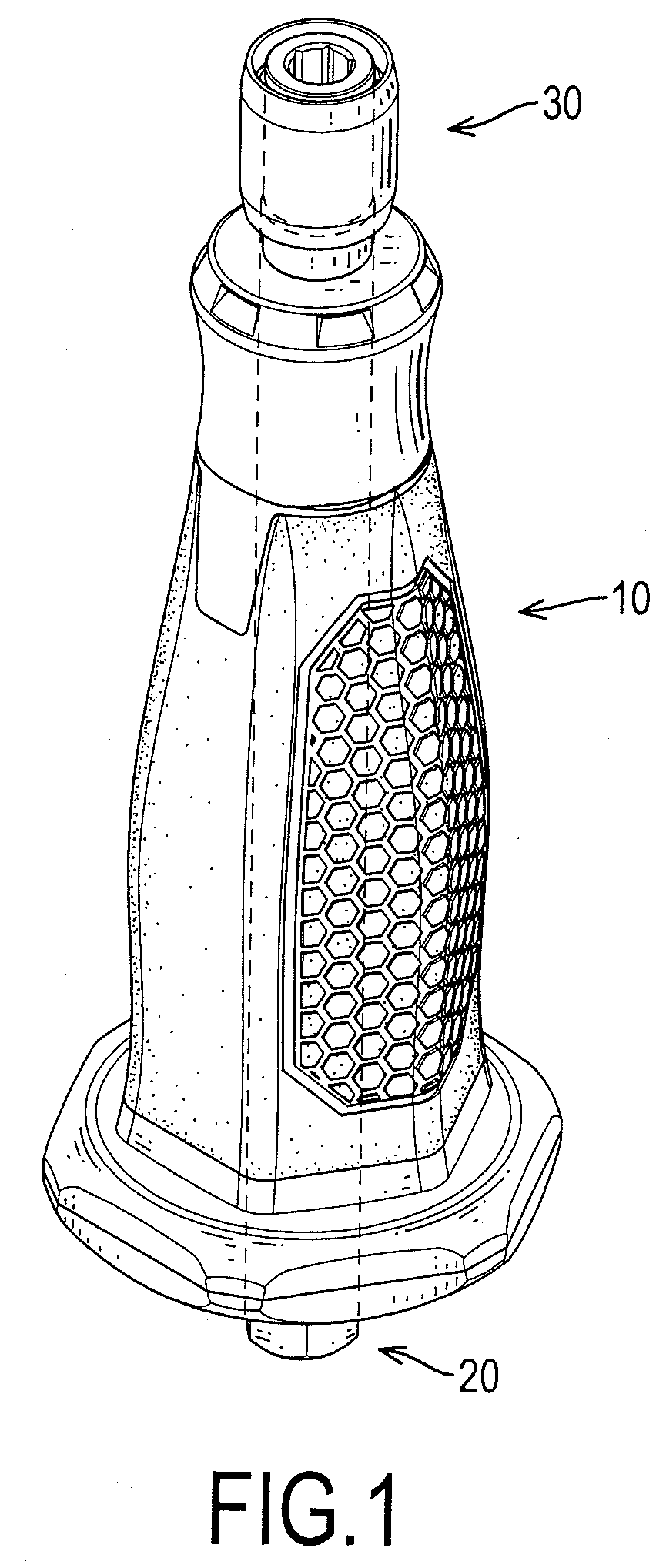

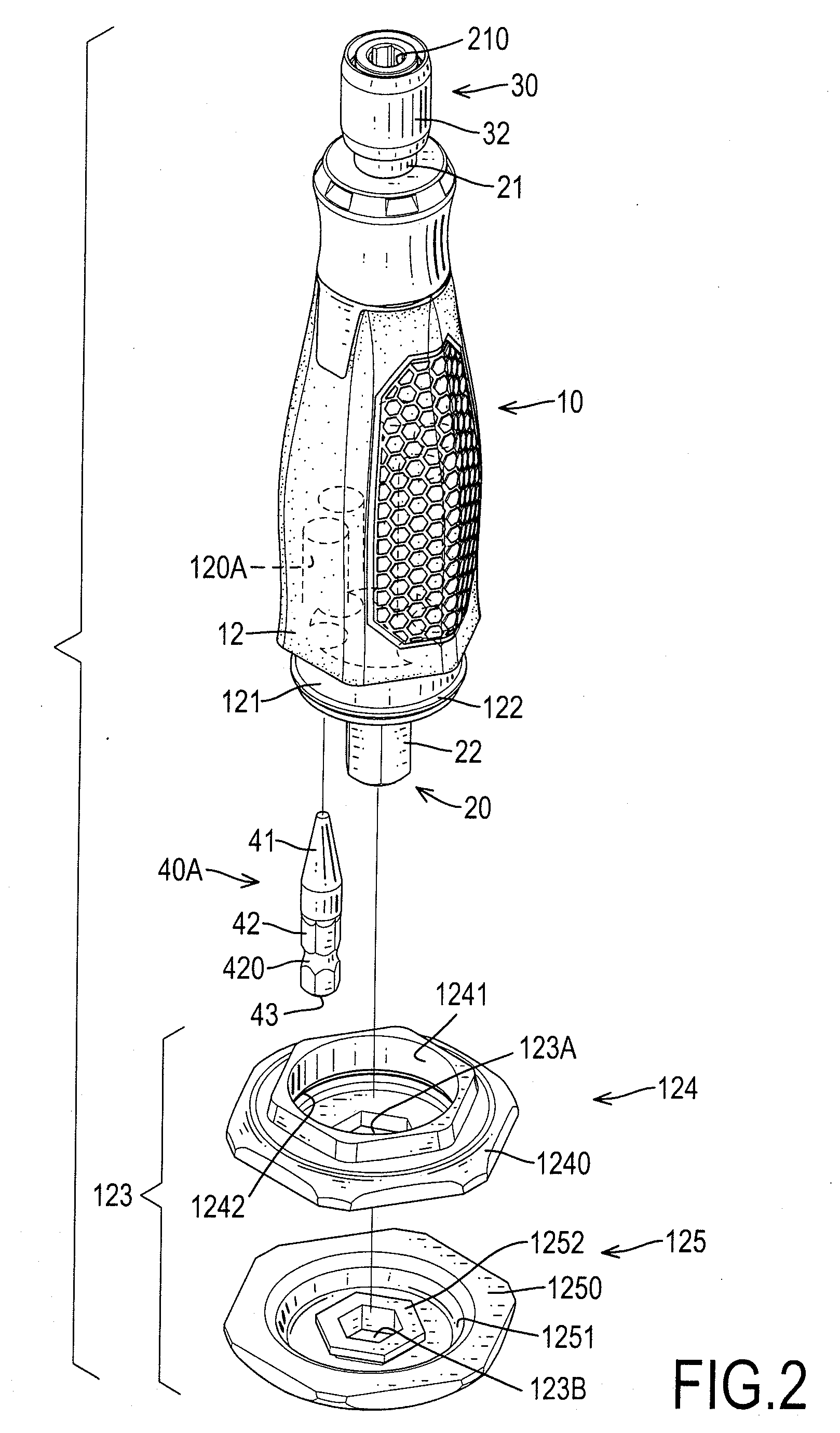

[0022]With reference to FIGS. 1, 3 and 5, a multi-use punch in accordance with the present invention comprises a core (20), a handle (10), a chuck (30), and at least one tool head (40A, 40B, 40C, 40D).

[0023]With reference to FIG. 4, the core (20) is metal and has a chuck end (21) and a butt end (22).

[0024]The chuck end (21) of the core (20) has a head hole (210), a wall (211), a chuck hole (213), an optional shoulder (212) and an optional spring mount (214). The head hole (210) is non-circular and may be hexagonal. The chuck hole (213) is formed through the wall (211) and communicates with the head hole (210). The shoulder (212) is formed on the wall (211) and protrudes into the head hole (210).

[0025]The butt end (22) of the core (20) may be hexagonal in cross section. With further reference to FIG. 2, the handle (10) is mounted around the core (20) and has a butt end (12) and an optional grip, and may be plastic or rubber.

[0026]The butt end (12) of the handle (10) has at least one ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lengths | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

| returning force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com