Step trash can having integrated base and base liner

a trash can and integrated technology, applied in the field of trash can assemblies, can solve the problems of undesirable spillage of waste materials inside the trash can, the trash bag slipping from the mouth of the trash can the trash bag slipping into the interior and falling into the interior, etc., to achieve convenient, effective deployment, use and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The present description is of the best presently contemplated modes of carrying out the invention. This description is made for the purpose of illustrating the general principles of the invention and should not be taken in a limiting sense. The scope of the invention is best determined by reference to the appended claims. The invention has been described herein in reference to various embodiments and drawings. It will be appreciated by those skilled in the art that variations and improvements may be accomplished in view of these teachings without deviating from the scope and spirit of the invention.

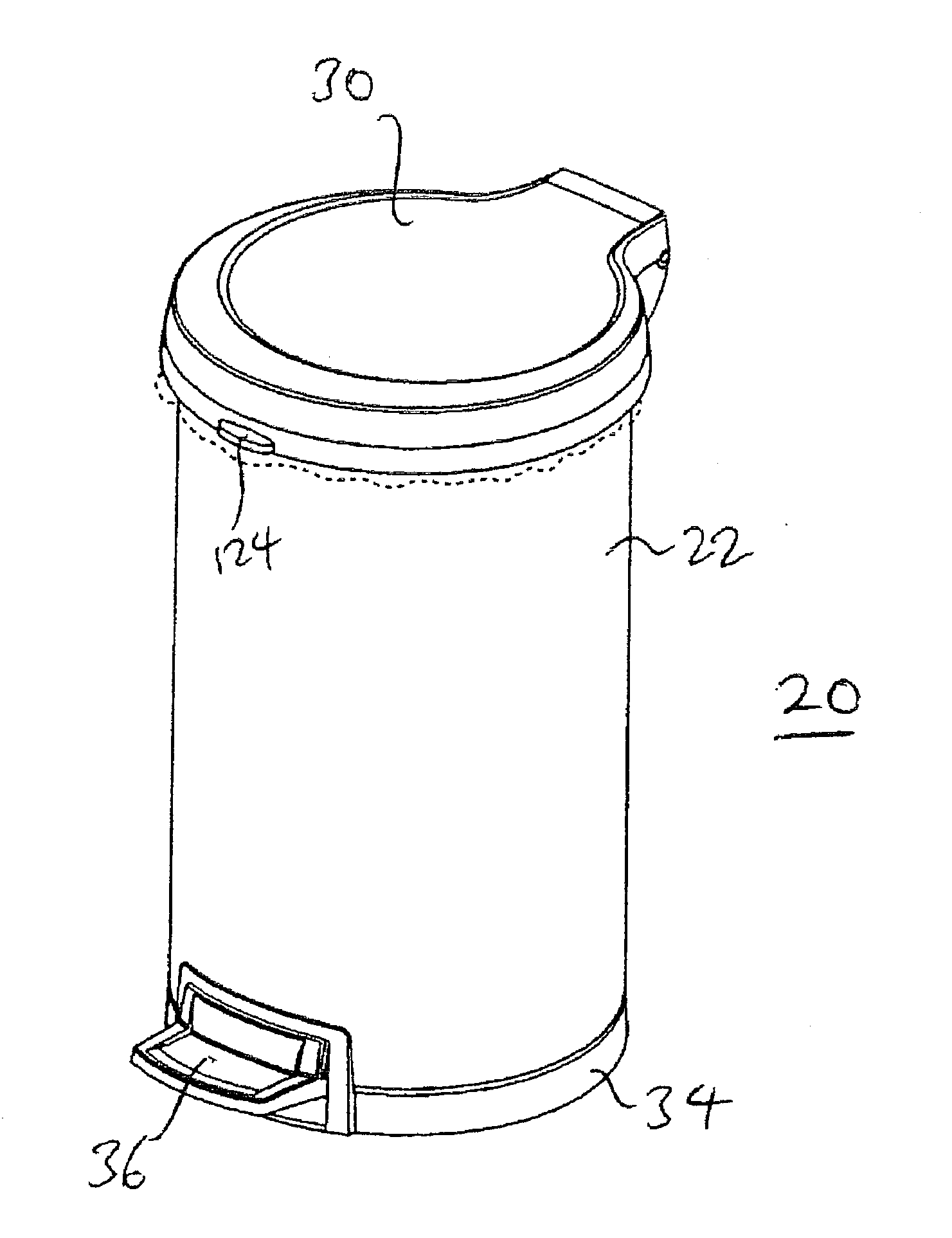

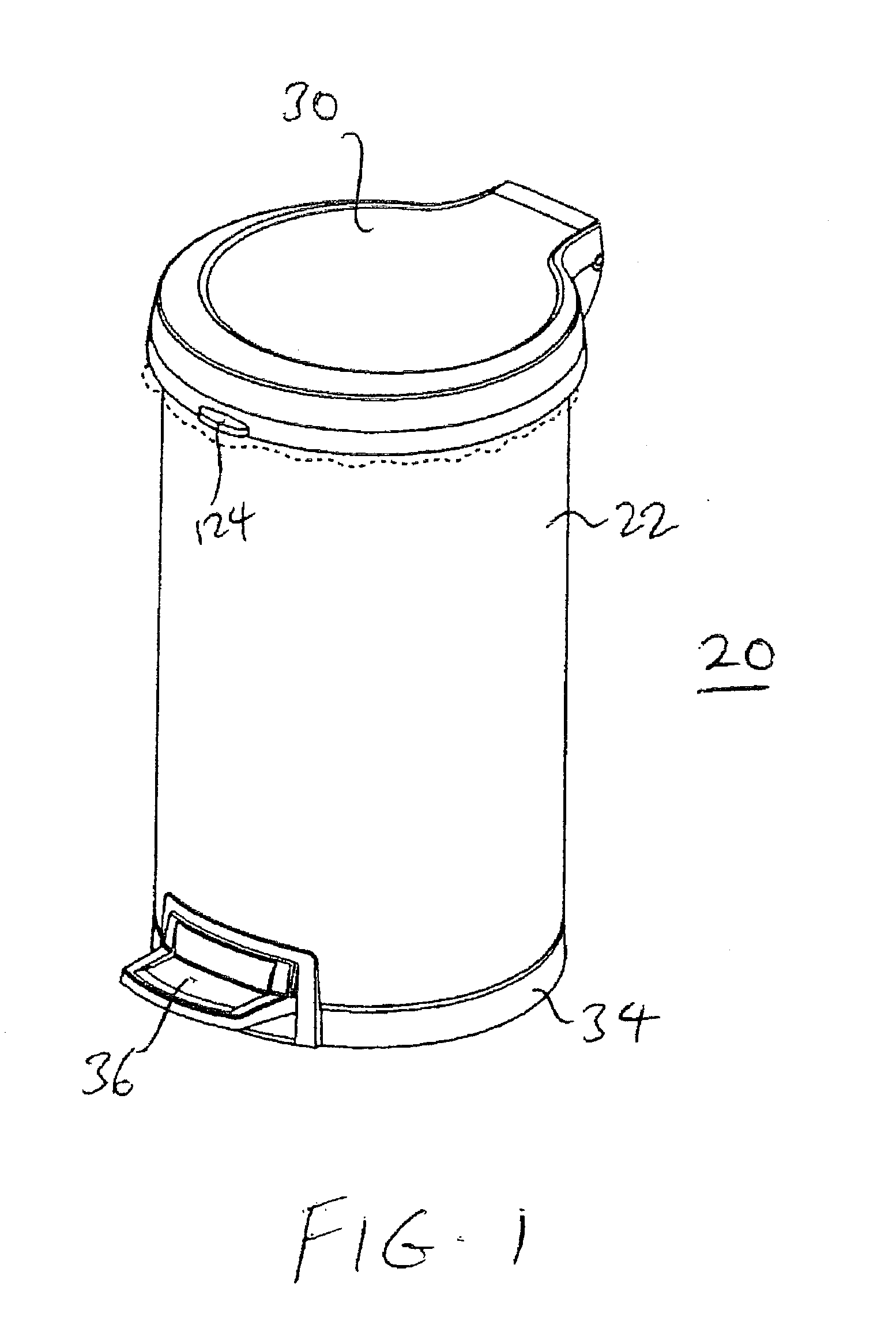

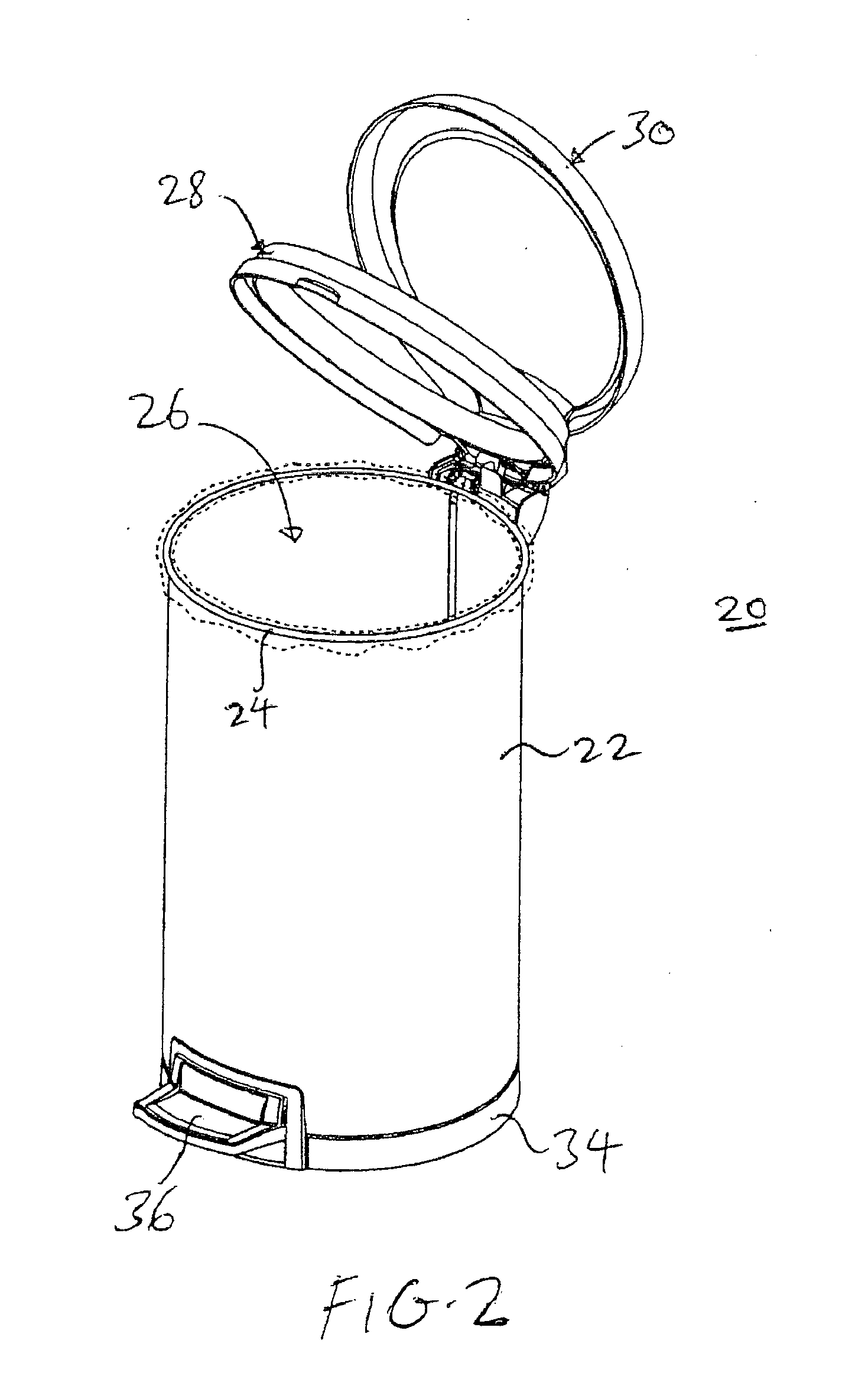

[0034]FIGS. 1-8 illustrate one embodiment of a trash can assembly 20 according to the present invention. The assembly 20 has a shell or canister body 22 that can be made from either plastic or metal. The shell 22 is an enclosing wall which can have any desired shape, including oval, triangular, rectangular, square or circular (among others), although the shell 22 is illustrated in F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com