Mitten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

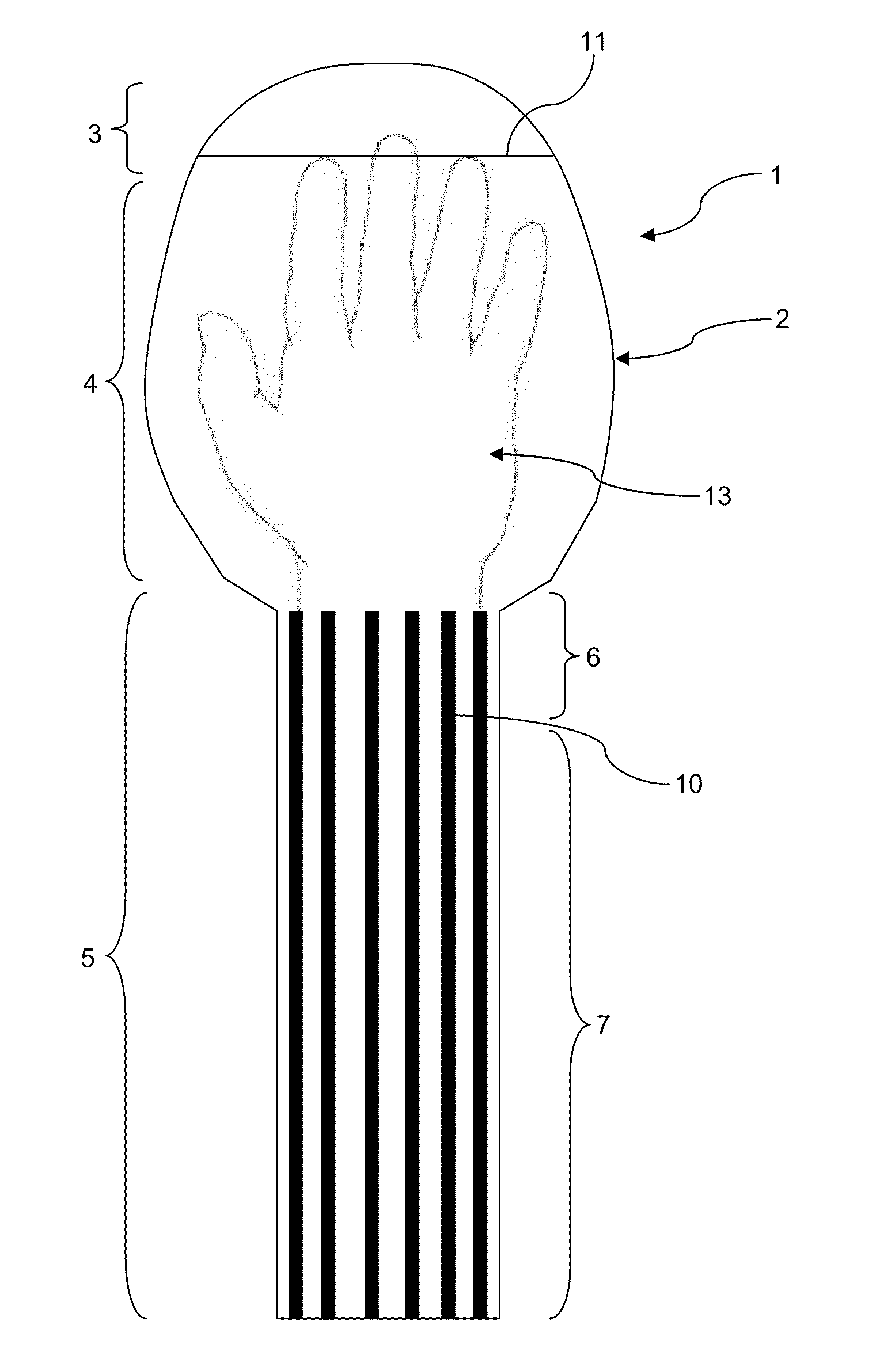

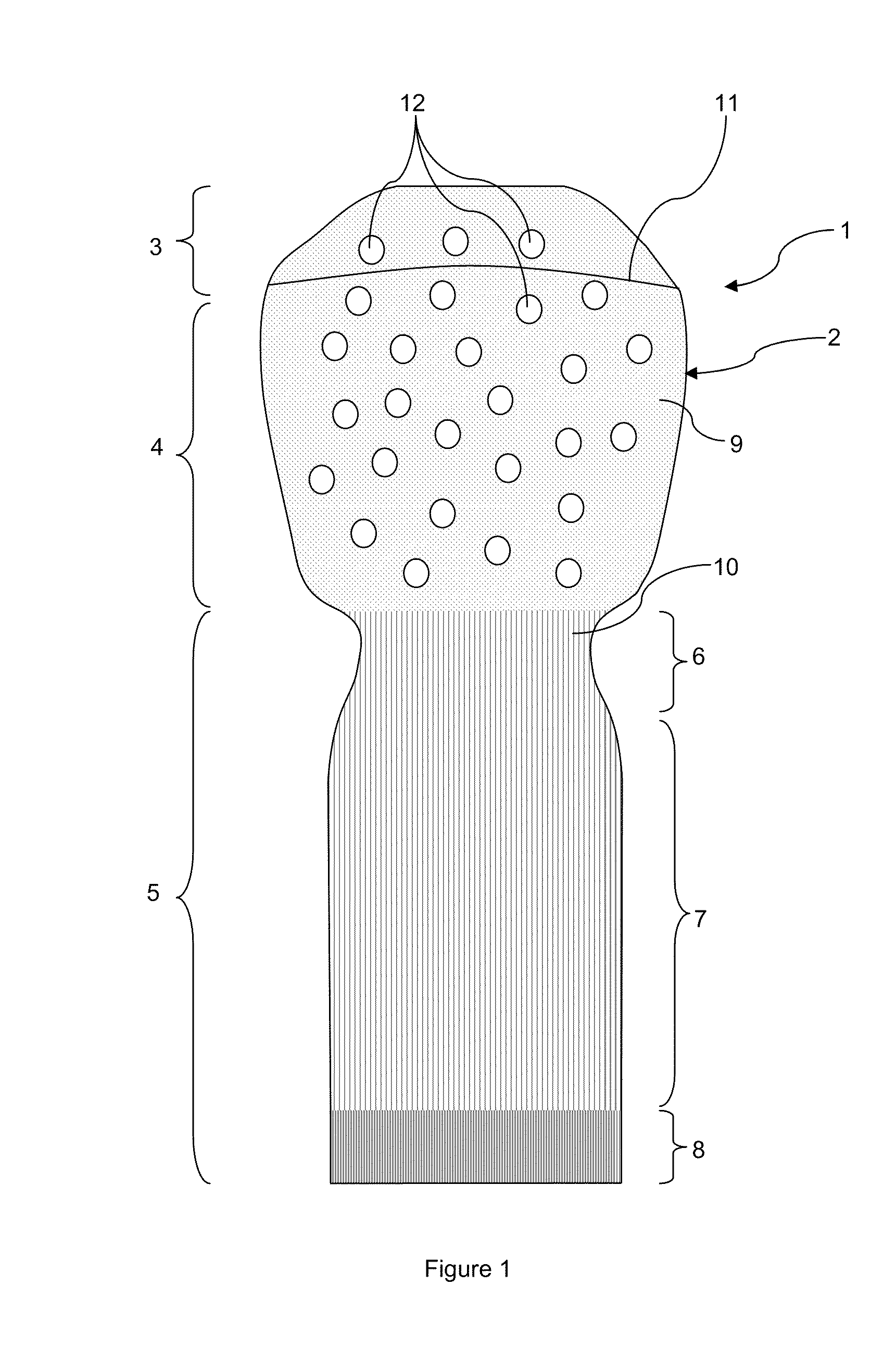

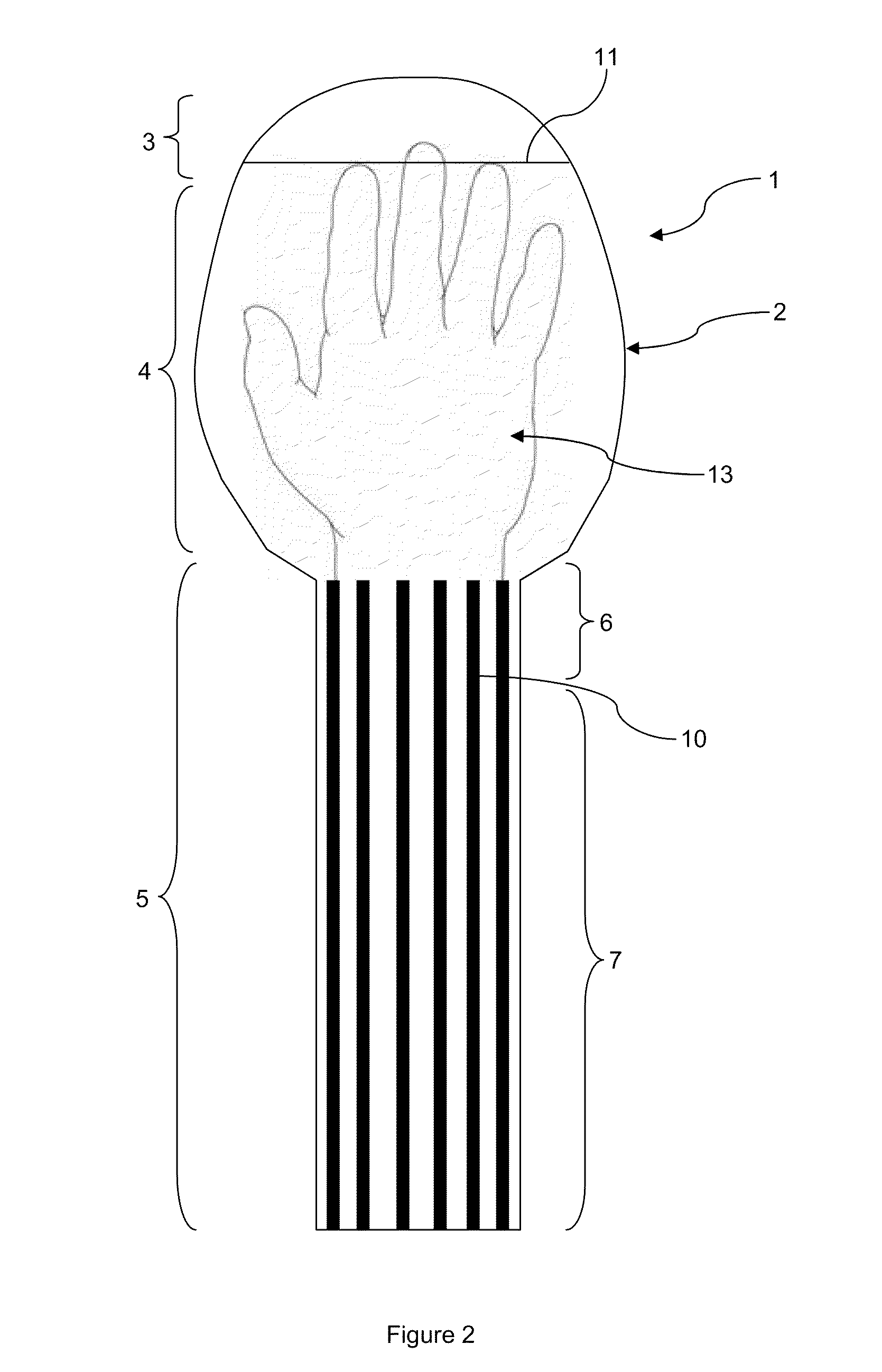

[0043]FIG. 1 shows a thumb-less mitten 1 is made from a seamless tube of knitted fabric 2. The mitten 1 comprises a first end section 3 at which the tube 2 is closed by a recessed and flat seam 11. The seam 11 is a lintoe seam which uses nylon thread. Immediately next to the first end section 3, the mitten 1 has a hand section 4, which is designed to accommodate the hand of a user. It will be appreciated that the user's hand (e.g. the ends of their fingers) can also be partially positioned in the first end section 3. The first end section 3 and the hand section 4 are both made of a plain knit terry fabric, with the terry loops (not shown) facing the interior of the mitten 1; the material is plain knit on 24 gauge (112 needle machine). The first end section 3 and hand section 4 are knitted from a material which is a blend of merino wool, acrylic and nylon (polyamide), for example approximately in the following amounts: 44% merino wool, 44% acrylic and 12% nylon.

[0044]The mitten 1 fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com