Frame-less, Split Pipe Wiper

a wiper and split-pipe technology, applied in the field of apparatus, can solve the problems of mud clinging to the exterior of the pipe or tubing, affecting the cleaning effect, polluting the environment, etc., and achieve the effect of simple, convenient installation and robust design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]While the present invention will be described with reference to preferred embodiments, it will be understood by those who are skilled in the art that various changes may be made and equivalents may be substituted for elements thereof without departing from the scope of the invention. In addition, many modifications may be made to adapt a particular situation or material to the teachings of the invention without departing from the essential scope thereof. It is therefore intended that the present invention not be limited to the particular embodiments disclosed as the best mode contemplated for carrying out this invention, but that the invention will include all embodiments and legal equivalents thereof.

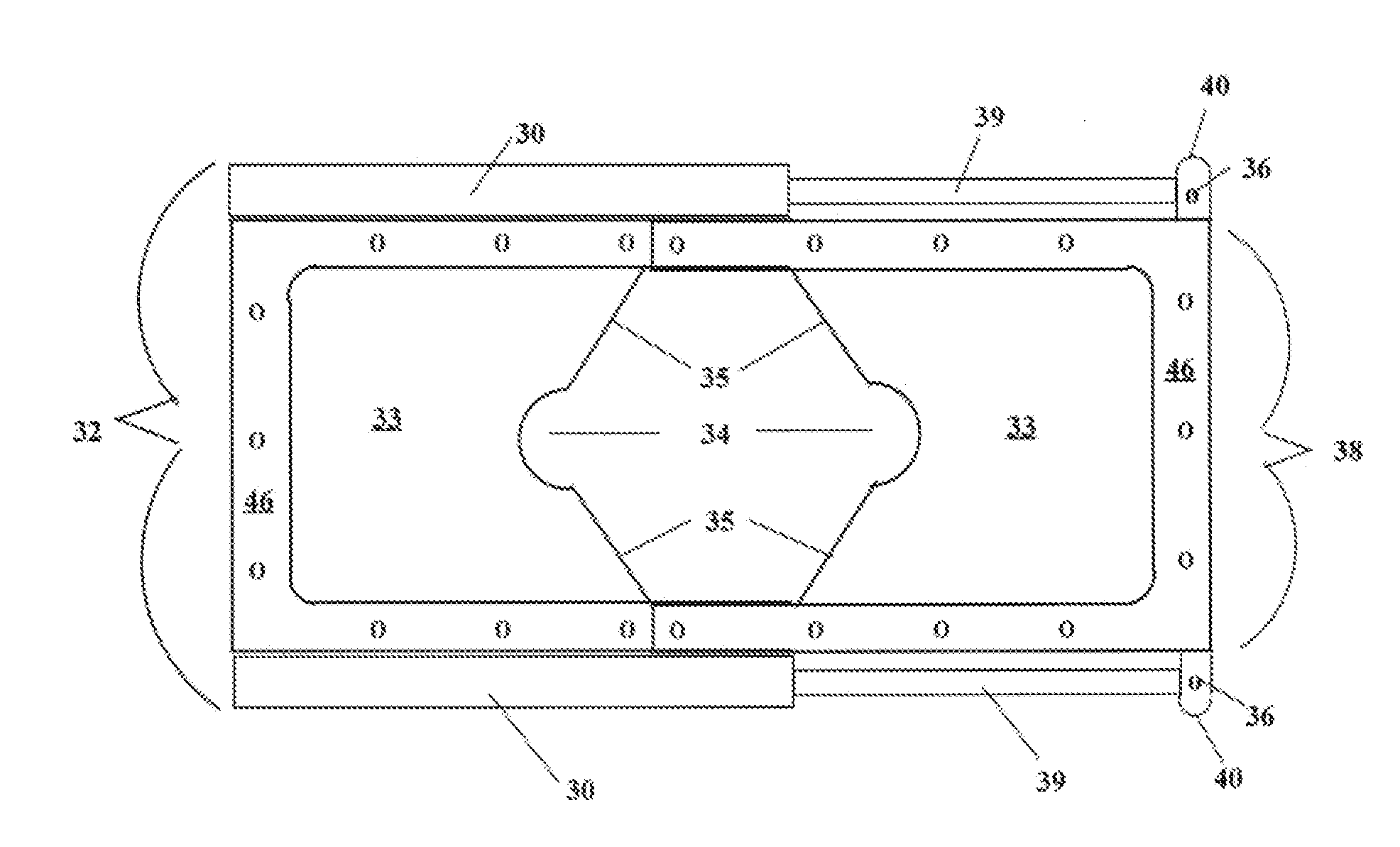

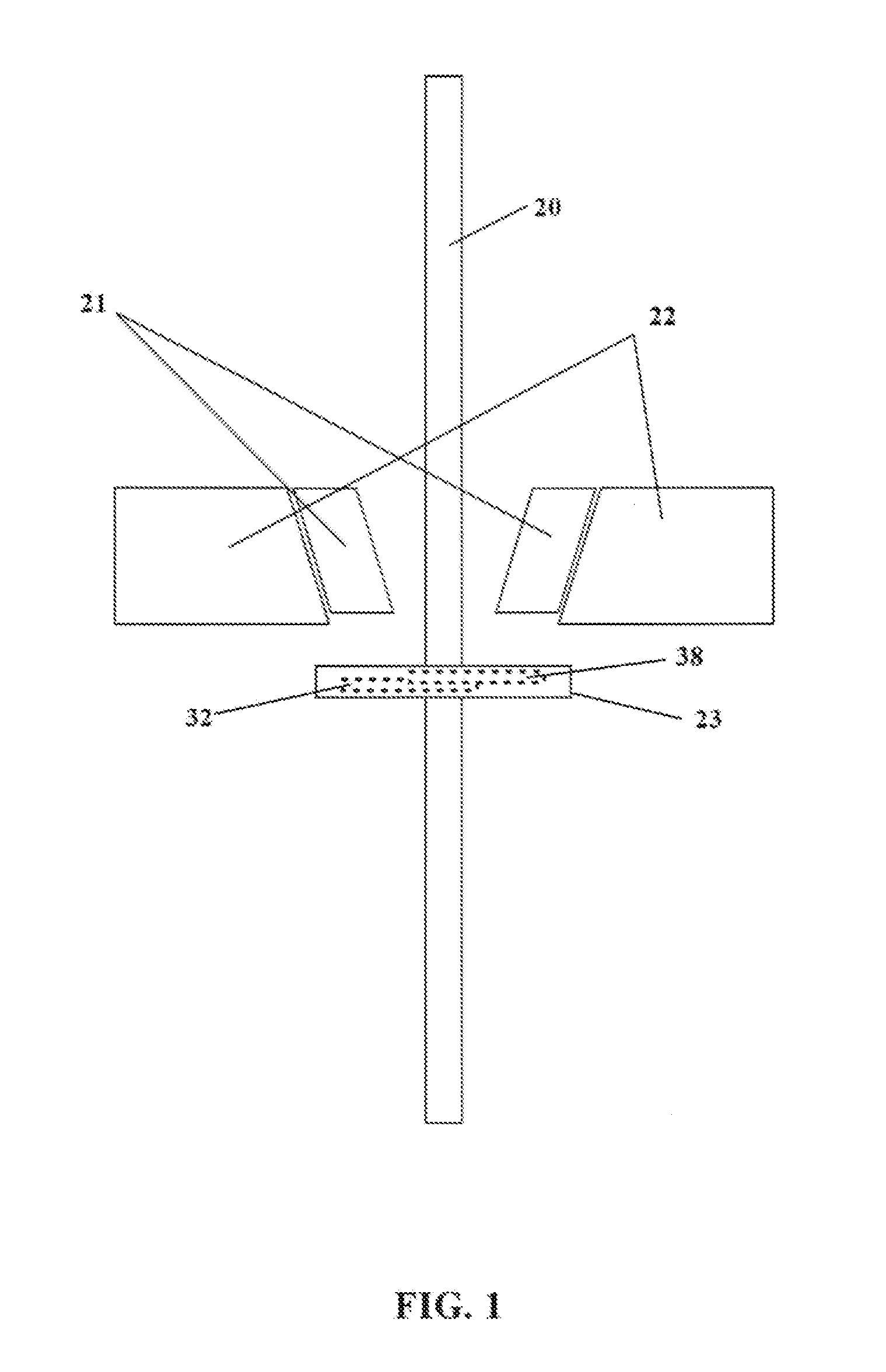

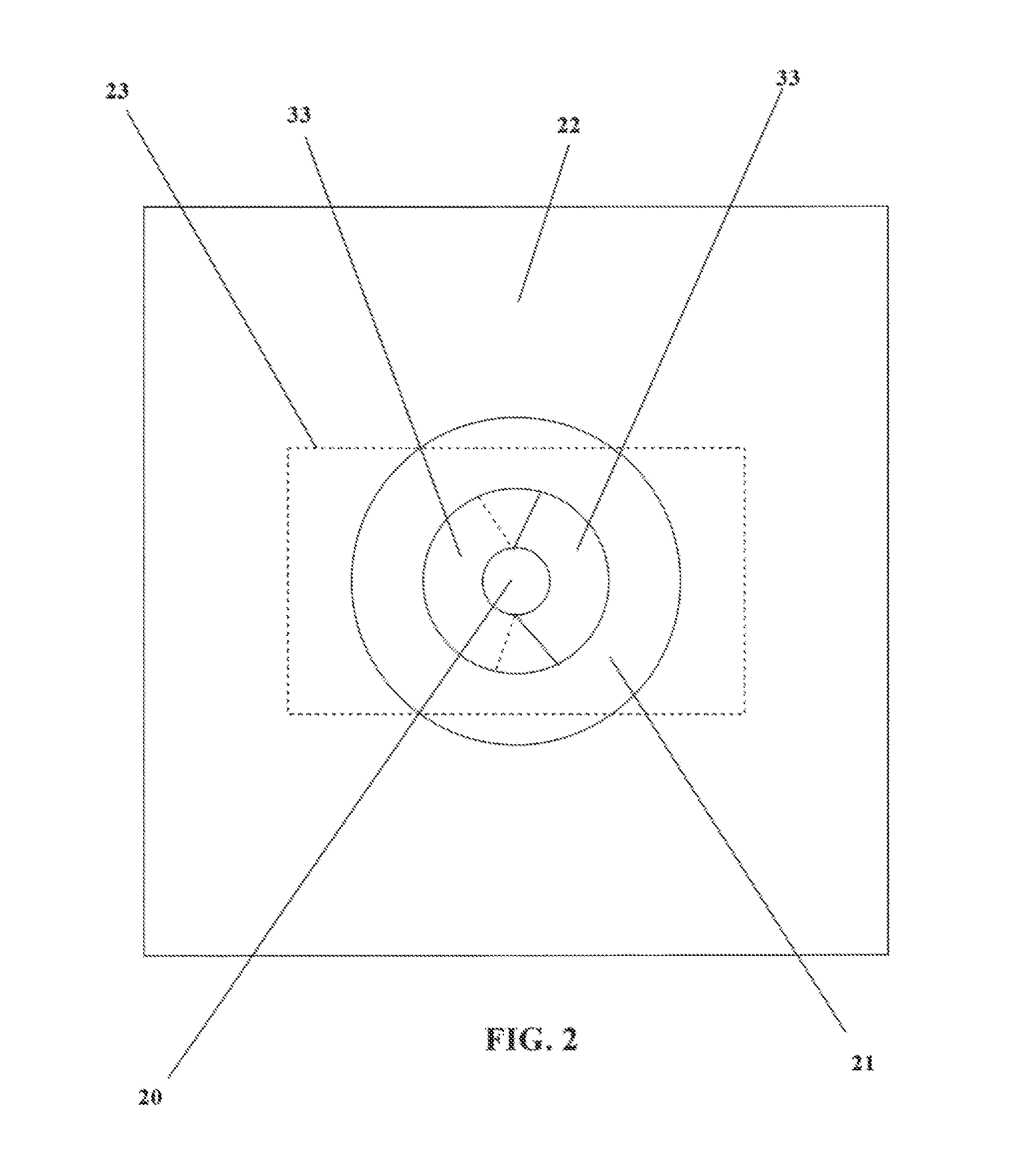

[0029]Looking at FIG. 1, drill pipe (20) is being wiped as it is pulled from the hole through the rotary table (22) and master bushings / slips (21) while the disclosed invention (23) disposed below rotary table (22) and is stripping and wiping the mud (25) from the exterior of dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com