Ballistic Groin Protector

a technology of groin protector and ballistic shield, which is applied in the direction of protective clothing, protective equipment, weapons, etc., can solve the problems of sacrificing its protective function and causing discomfort to the wearer, and the protective element that is too sti

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

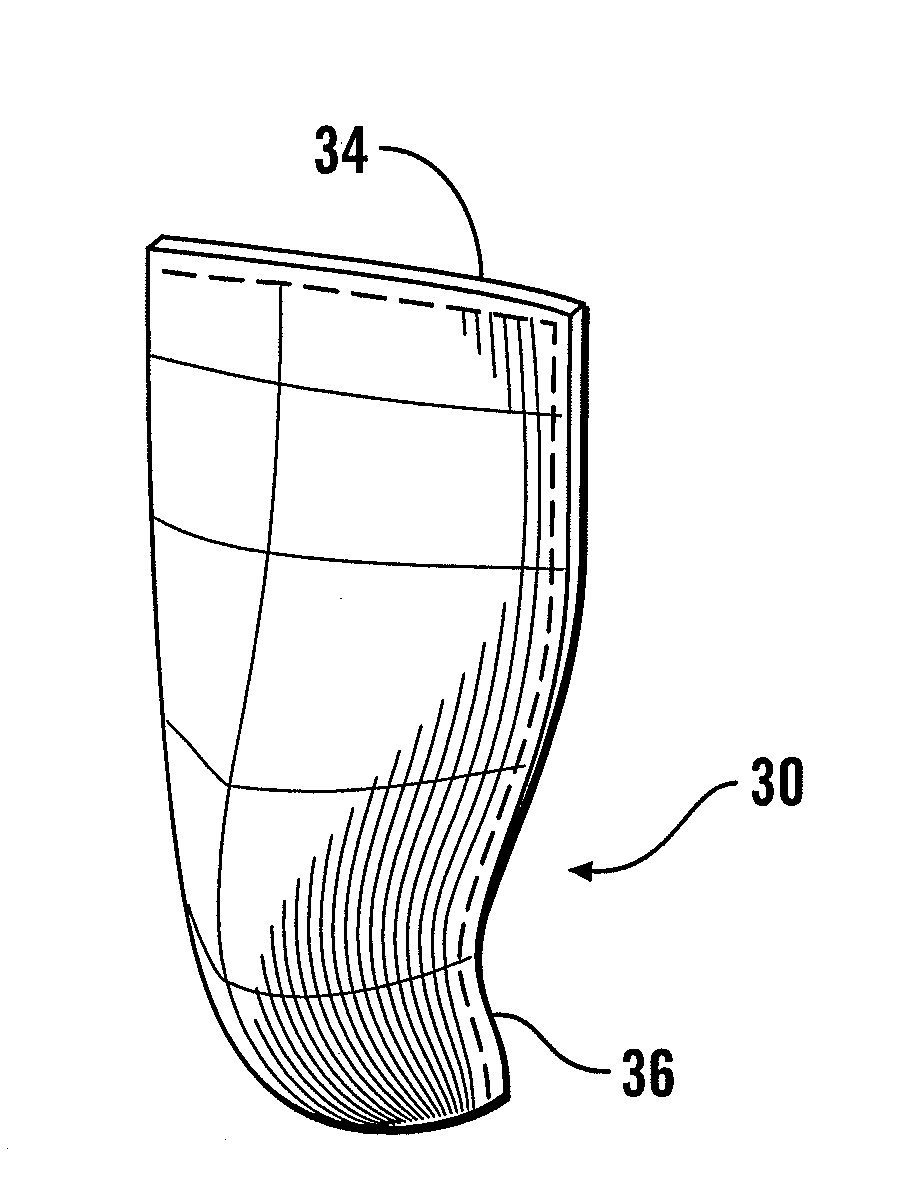

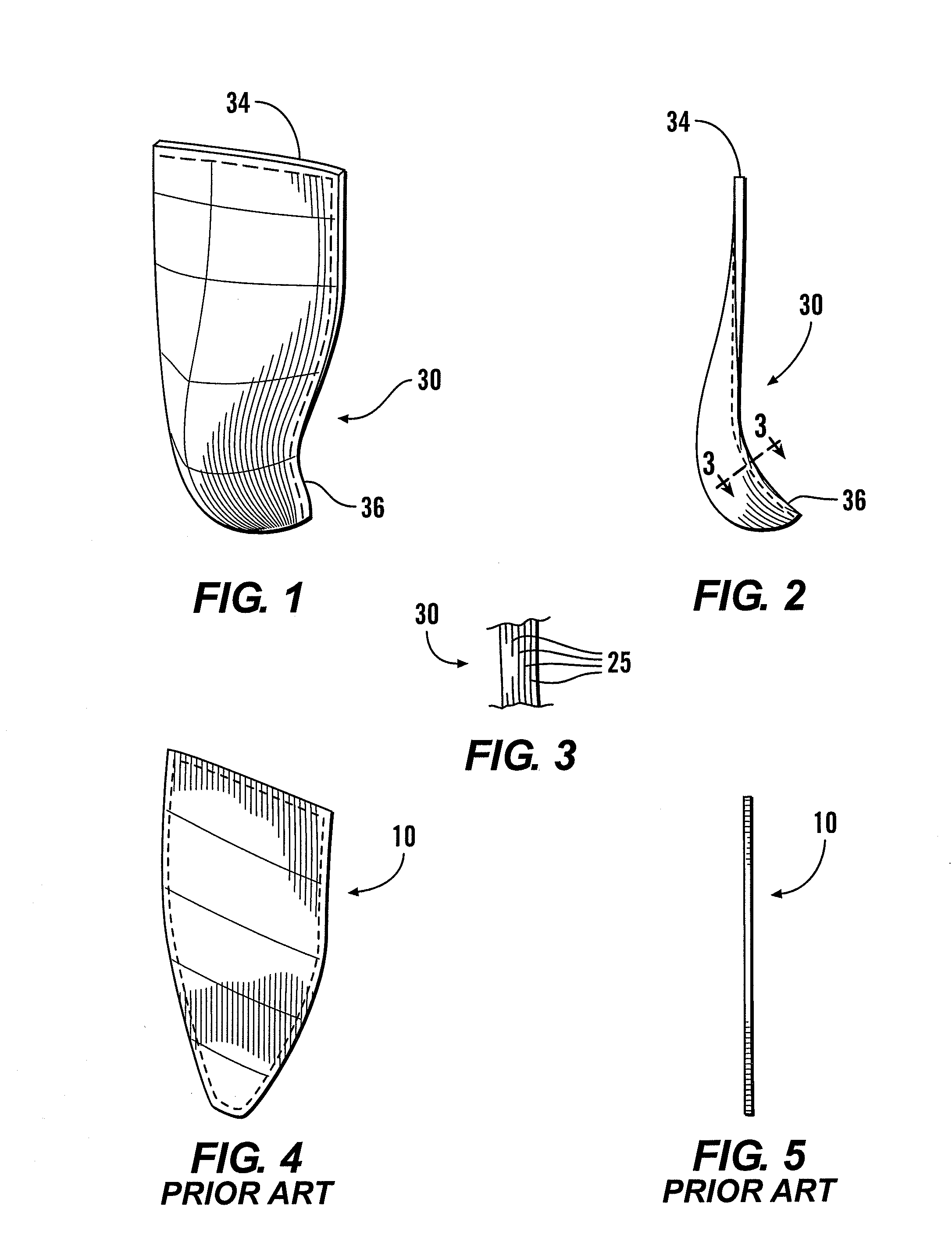

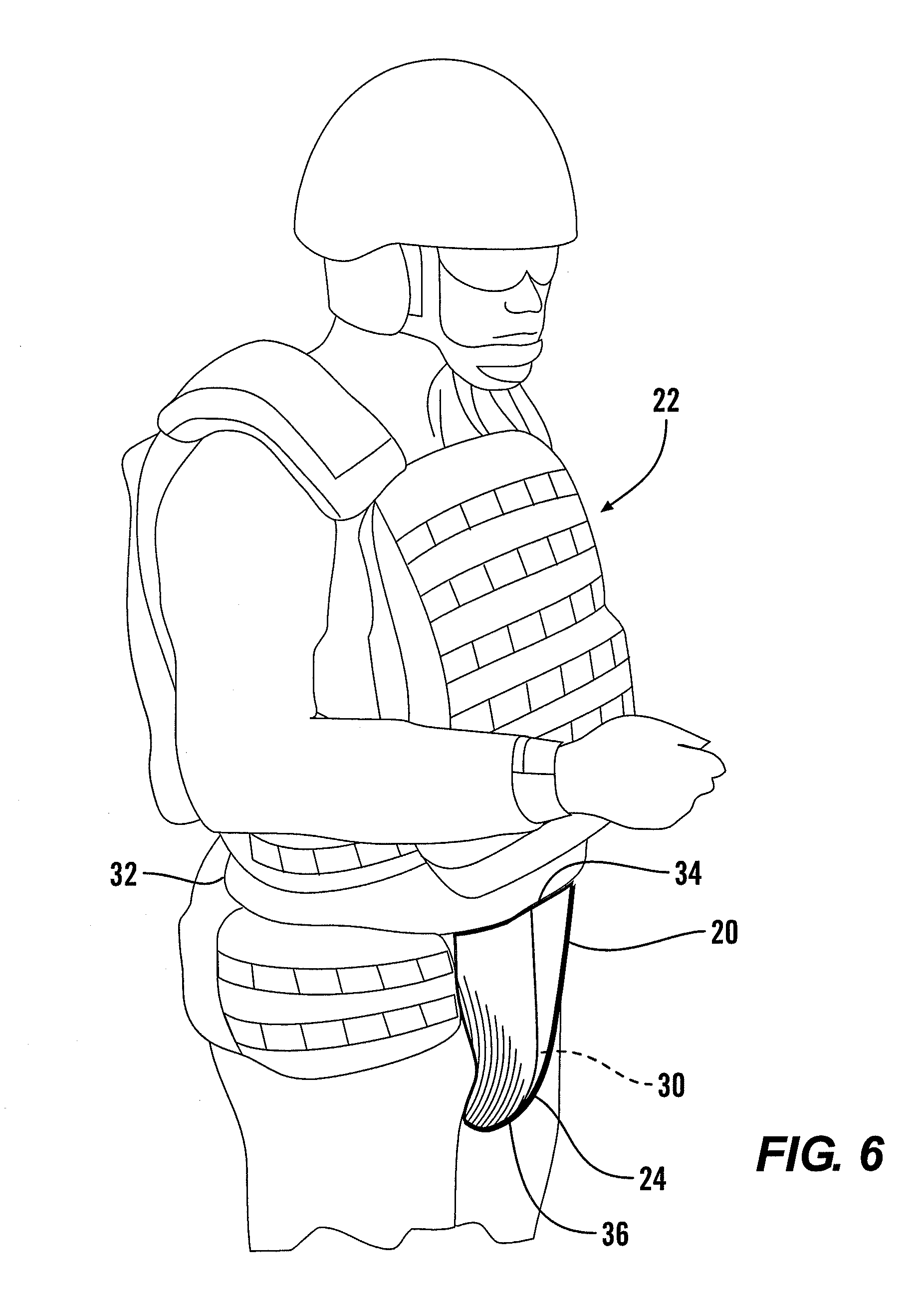

[0020]Referring more particularly to FIGS. 1-7, wherein like numbers refer to similar parts, a compliant body armor ballistic element 20 is shown in FIGS. 1-3. The component 20 will typically be worn together with some type of armored vest 22, as shown in FIG. 6. The component 20 may include a fabric bag 24 which receives a soft armor ballistic element 30, as shown in FIGS. 2 and 3 and which is a thin compound curved concave element, which may be about five-sixteenths inches thick. The enclosing sewn fabric bag 24 protects the ballistic element 30 from wear and soiling. This bag may be a lightweight nylon material. The element 30 is formed as a stack of multiple layers of ballistic material 25, for example material of Kevlar® fibers, or, for example, layers of material of Spectra® ultra high molecular weight polyethylene fibers from Honeywell. The stack is formed under heat and pressure with a resin as discussed below, and may be stitched around the periphery, in a quilted pattern, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com