Method for controlling a cooking point of a gas oven and device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

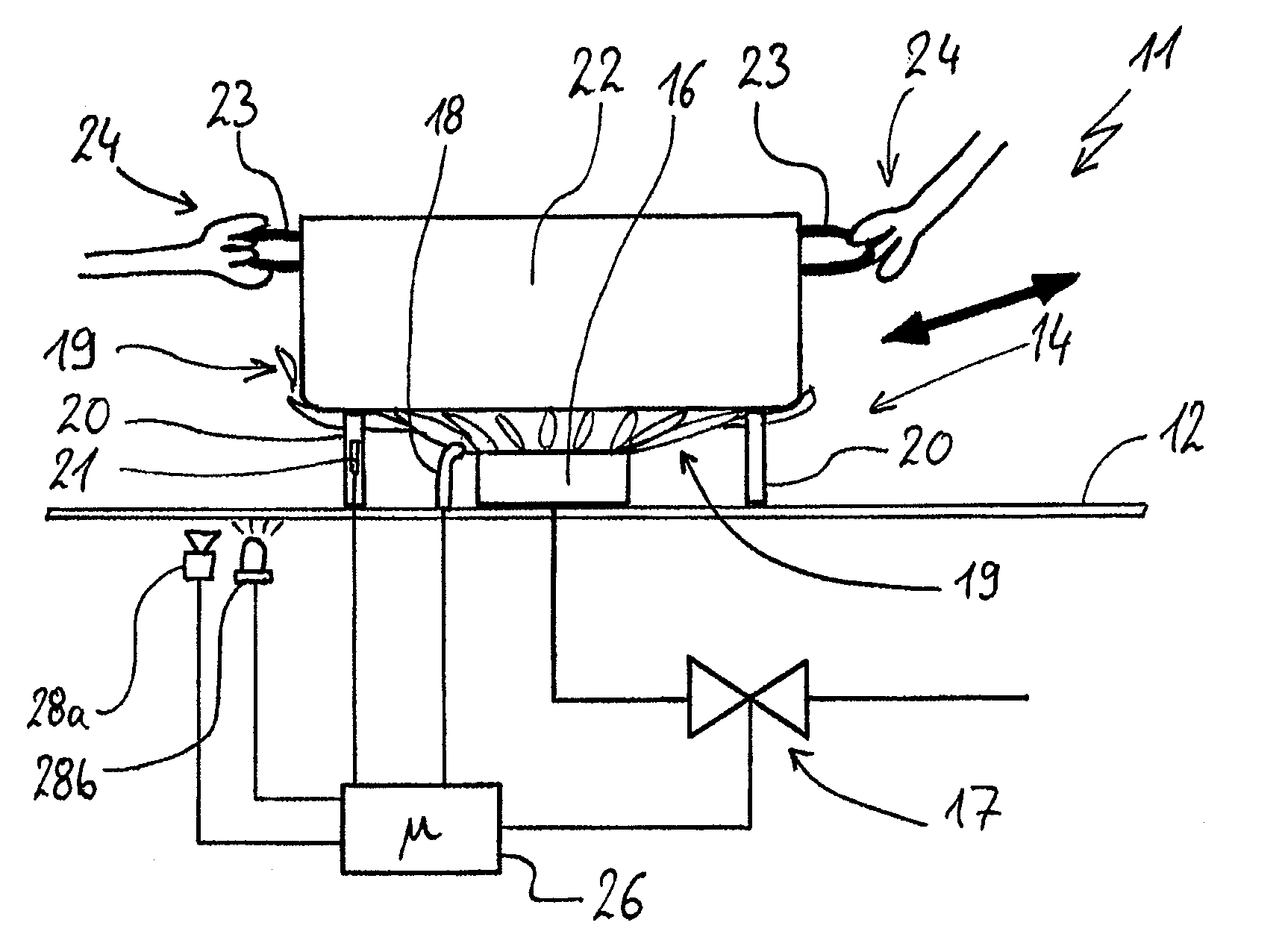

[0023]FIG. 1 illustrates a gas hob 11 as a device according to the invention, on which the method according to the invention can be carried out. The gas hob 11 has a conventional hob panel 12, and a cooking point 14 thereof is illustrated. The cooking point 14 has a conventional gas burner 16 with a gas valve 17 arranged under the hob panel 12, from which valve said burner is supplied. Provided at the gas burner 16 is an ignition device 18 and advantageously a monitoring device (not illustrated) for the gas flames 19. An essentially conventional pan support 20, on which a pan 22 is placed over the gas burner 16 and the cooking point 14, is also provided. This pan support has yet further functions, as still to be explained below. As usual, the pan has side handles 23, which are being gripped by hands 24 of the user, for example because said user has just placed the pan 22 on again.

[0024]Provided on the gas hob 11 is a controller 26, which is connected not only to the gas valve 17, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com