Securing Brake Shoes to Brake Beams in a Railroad Car Retarder

a technology for rail cars and brake beams, applied in rail brake actuation, track brakes, railway braking systems, etc., can solve the problems of inability of the installer to torque the bolts connecting the brake shoes to the brake beams to their full theoretical load, and the loosening of the bolts. to the full load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

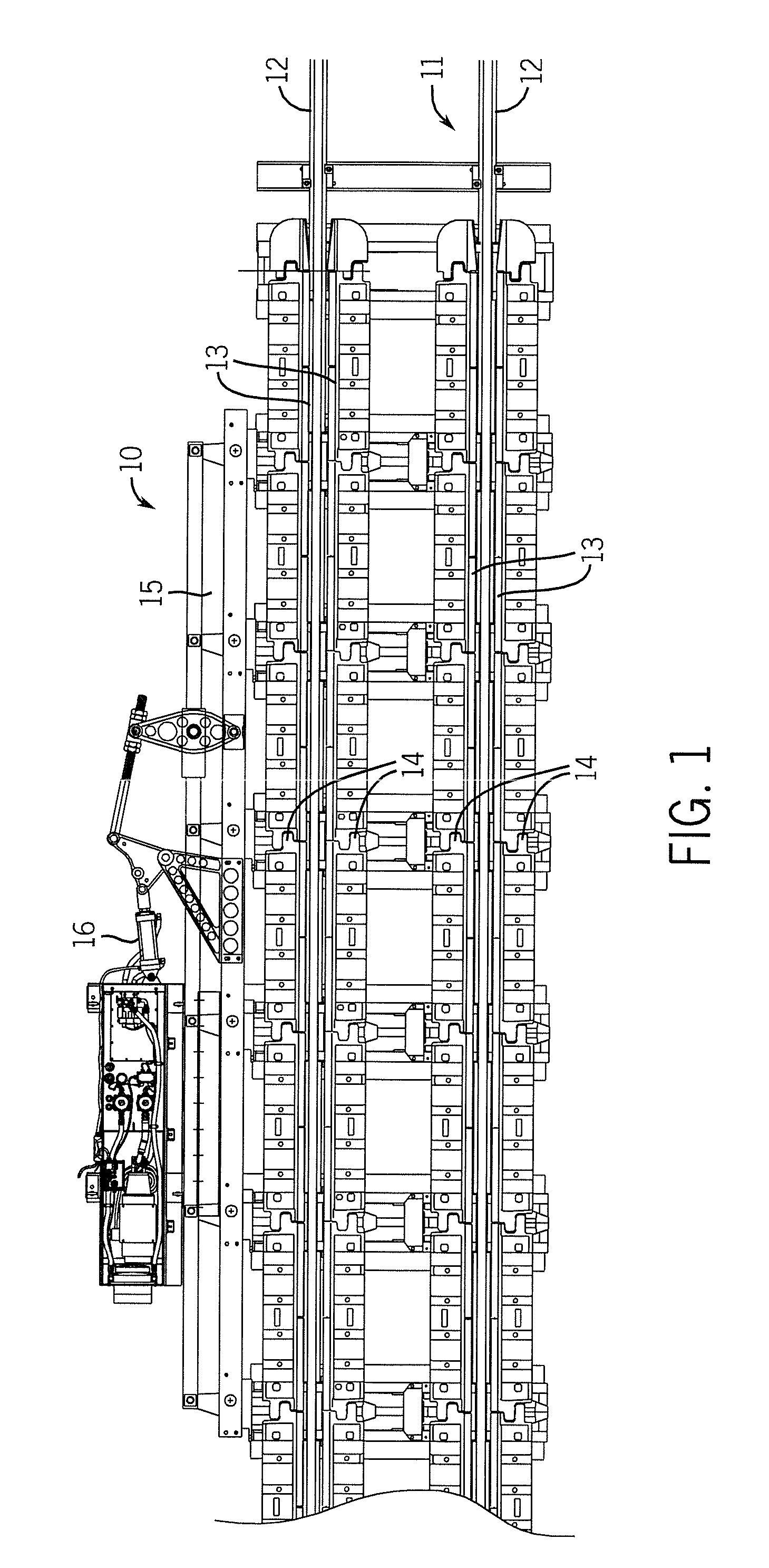

[0026]Referring to FIG. 1, a railroad car retarder 10 is shown mounted along a section of track 11 comprising a pair of conventional rails 12. Track 11 continues in both directions from the retarder with rail cars entering the retarder from one direction, being slowed by the braking action of the retarder, and existing the other end. Each retarder 10 includes linear series of pairs of parallel brake shoes 13 on opposite sides of and parallel to each of the rails 12. The brake shoes are attached to and carried by brake beams 14, which position the brake shoes above the tops of the rails 12 such that, when moved toward one another, the brake shoes engage the sides of the car wheels to effect a braking or retarding of the moving rail car, as is well known in the art.

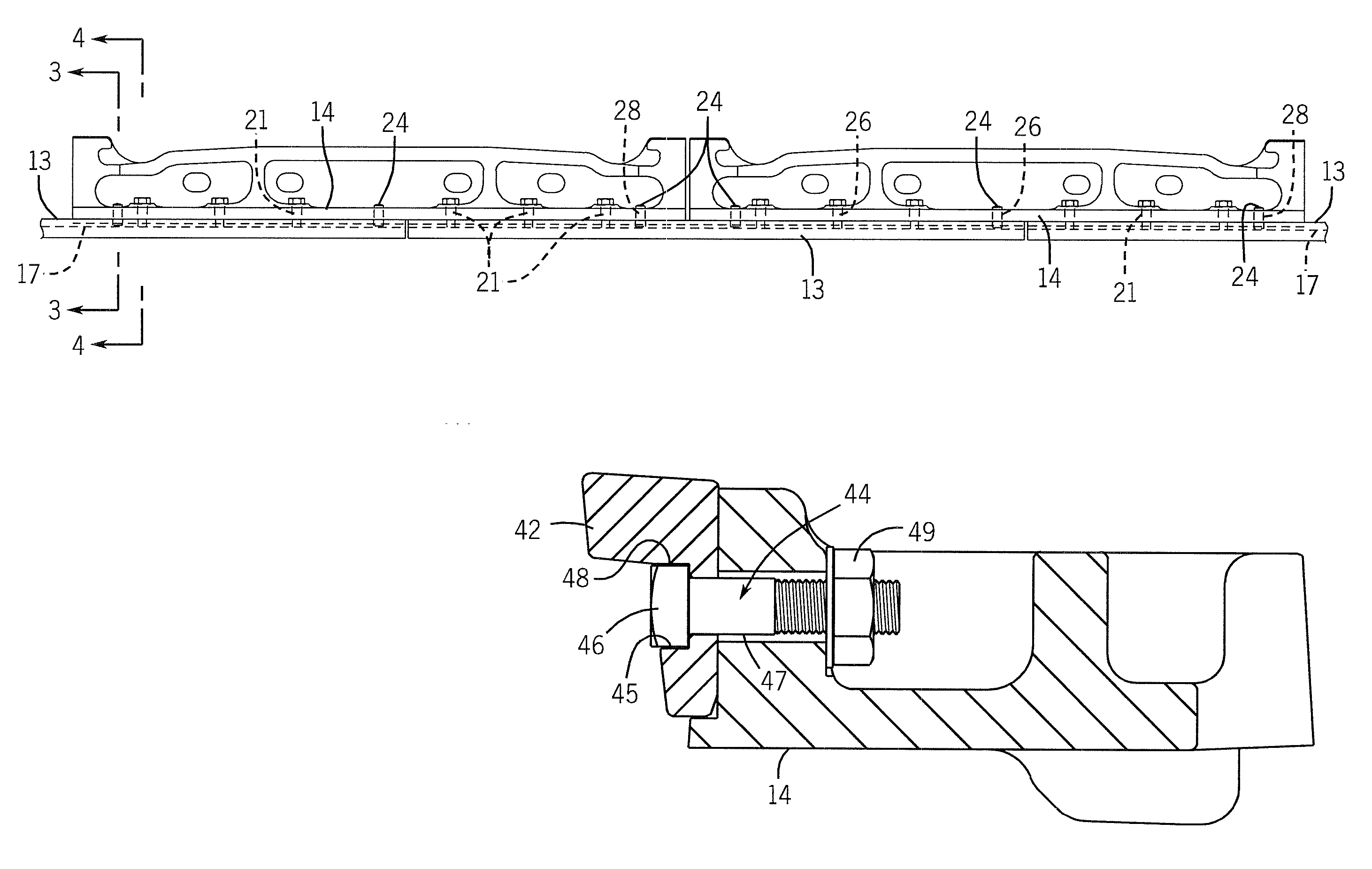

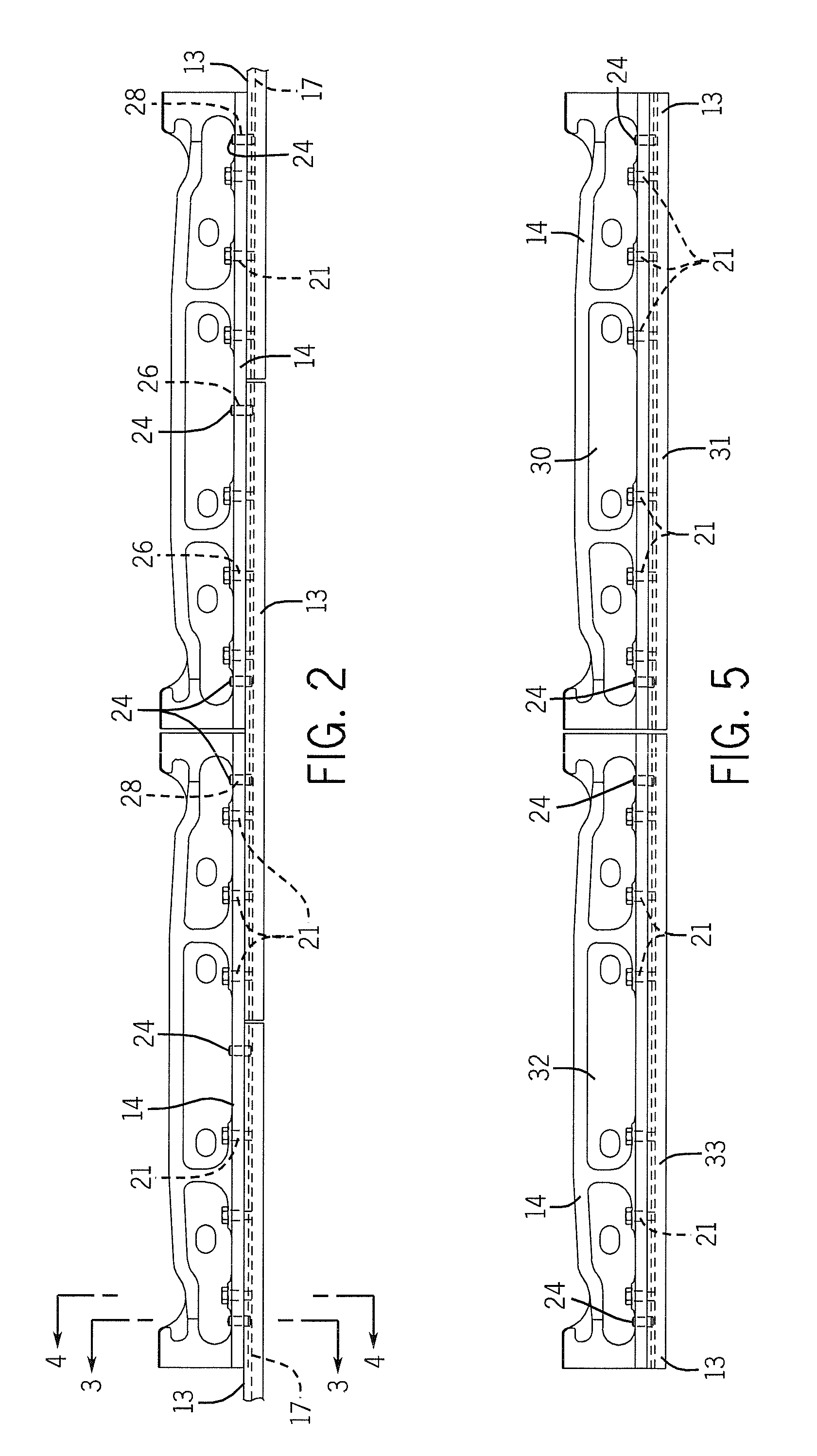

[0027]Referring also to FIG. 2, there is shown one of a pair of brake shoe assemblies 13 for one track 11 of a retarder. The partial assembly of FIG. 2 shows two adjacent brake beams 14 to which are attached three brake sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com