Extended short span tee for drywall ceiling

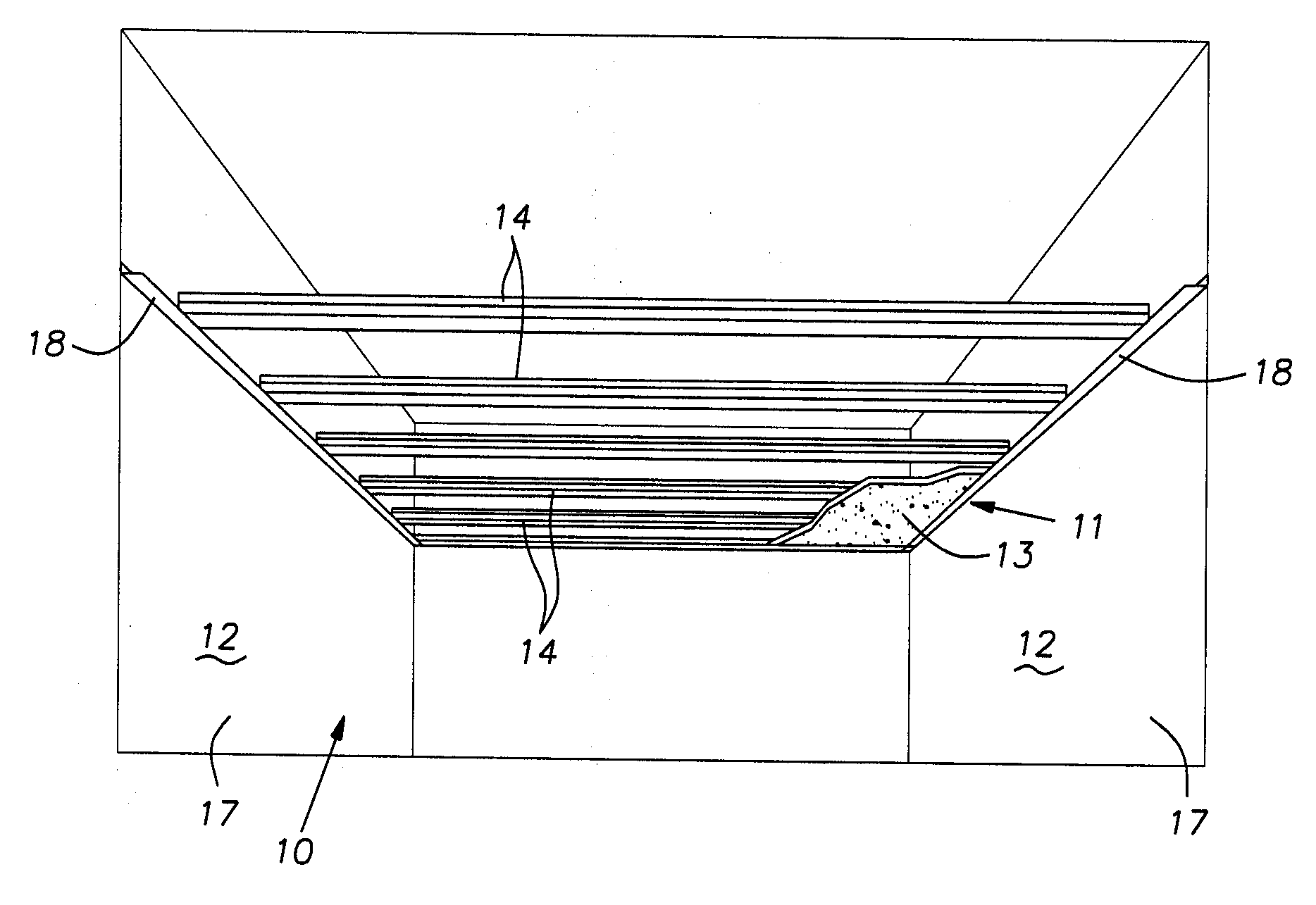

a drywall ceiling and short-span technology, applied in the field of short-span flat drywall ceiling construction, can solve the problems of increasing construction costs, incurred, and equipment frequently interferes with the installation of suspension wires, and achieves cost savings, increased section modulus, and effective rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

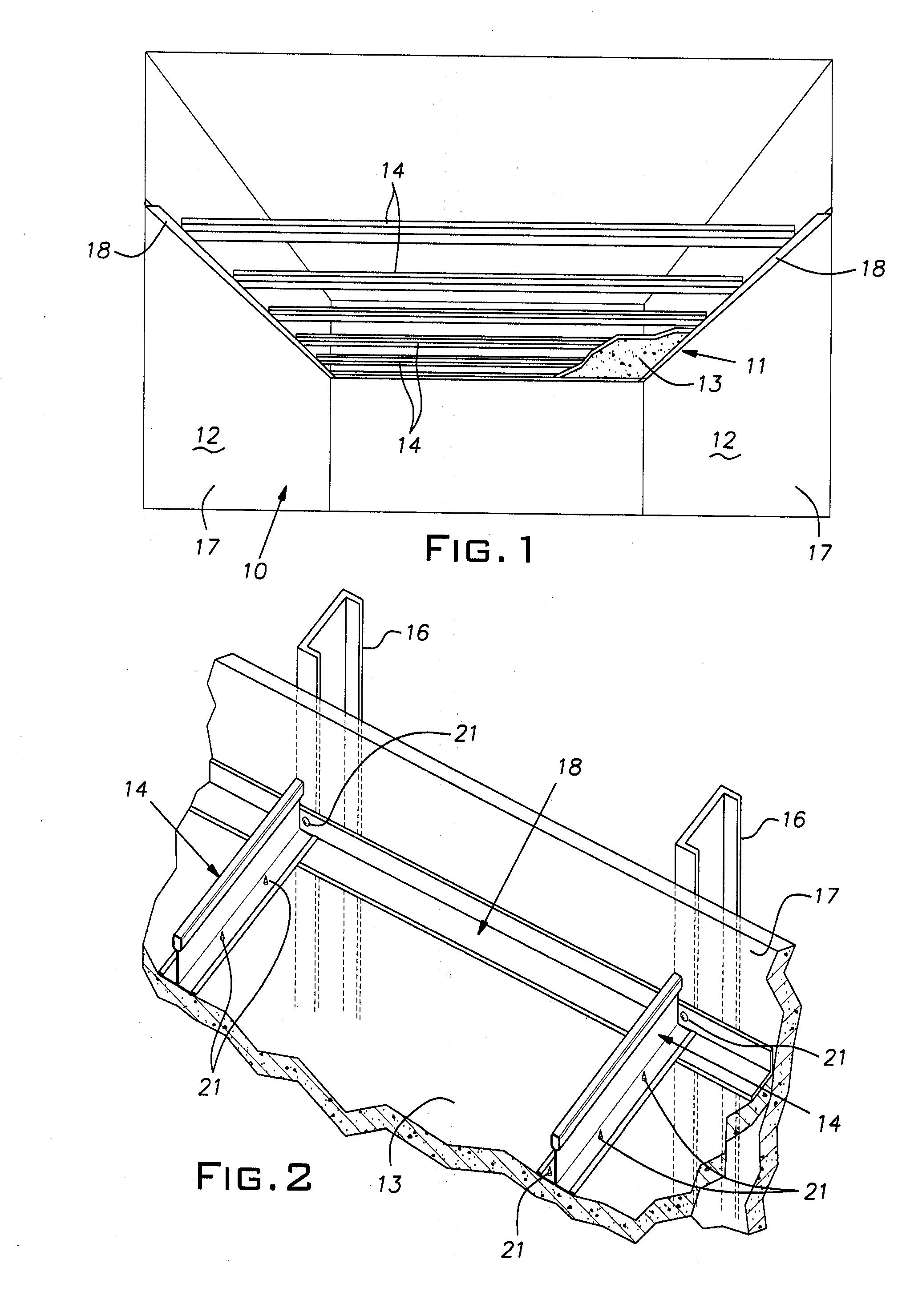

first embodiment

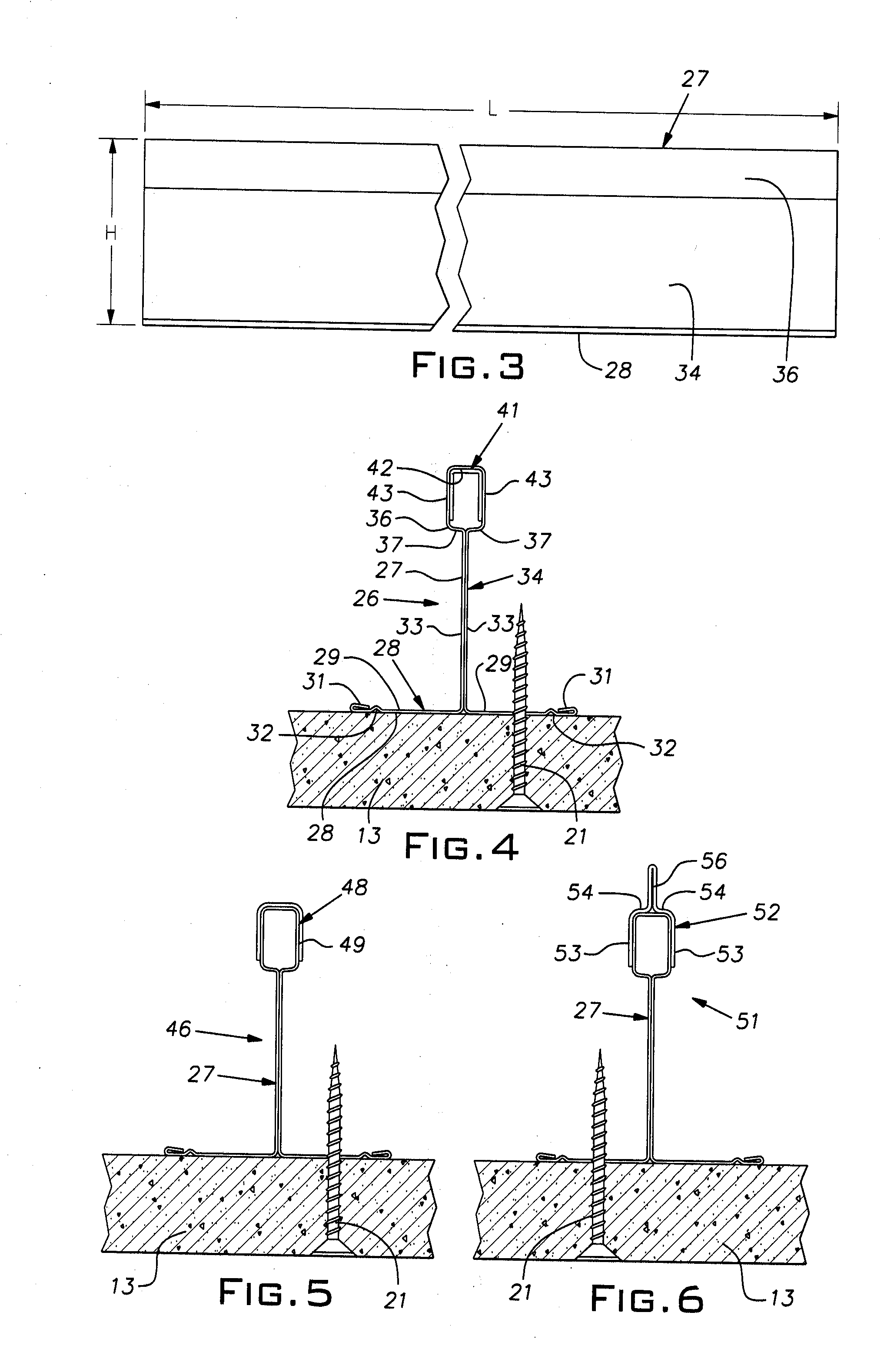

[0015]FIG. 4 illustrates a tee 26 in cross-section. The tee has a main body 27 roll-formed of a single strip of sheet metal. The strip is, for example, relatively light gauge stock being about 0.018″ galvanized (G40) hot-dipped steel (HDG). The form of the tee main body 27 is conventional. At the lower side, the tee main body 27 includes a single layer horizontal flange 28 comprising oppositely extending parts 29. Distal edges of the flange parts 29 have hems 31 folded over their upper sides. Adjacent and parallel to their distal edges, the flange parts 29 have small grooves 32 that serve to restrain screws from “skating” laterally off of the lower face of the flange 28 when being screwed into the flange. Additionally, the lower face of the flange 28 can be knurled, as is known, to stabilize a screw tip and further prevent it from skating across this lower flange face. At their proximal edges, the flange parts 29 merge integrally with respective layers 33 of a double layer or double...

second embodiment

[0019]FIG. 5 illustrates a tee 46 in cross-section. A tee main body can be identical to the tee main body 27 disclosed in connection with FIGS. 1-4. In the tee 46 of FIG. 5, an inverted channel 48 is fitted, cap-like, over the reinforcing bulb 36. Channel 48 is preferably roll-formed from a strip of sheet steel of a gauge somewhat heavier than the gauge of the main tee body 27. The channel gauge can be nominally a minimum of 0.024″, for example. The channel 48 includes a pair of sides 49 proportioned to closely abut the sides of the hollow reinforcing bulb 36 and to extend vertically over a major portion of the vertical height of the bulb. The channel 48 is rigidly fixed in place on the main body by appropriate staking, piercing, riveting, welding, or the like. The length of the channel 48 need not extend the full length of the main tee body 27 and can, for example, be half or more in length as the length of the tee main body and be centered lengthwise over the tee main body.

[0020]F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com