Field plate trench mosfet transistor with graded dielectric liner thickness

a dielectric liner and trench mosfet technology, applied in the field of semiconductor devices, can solve the problems of power dissipation and/or low area consumption during mosfet operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

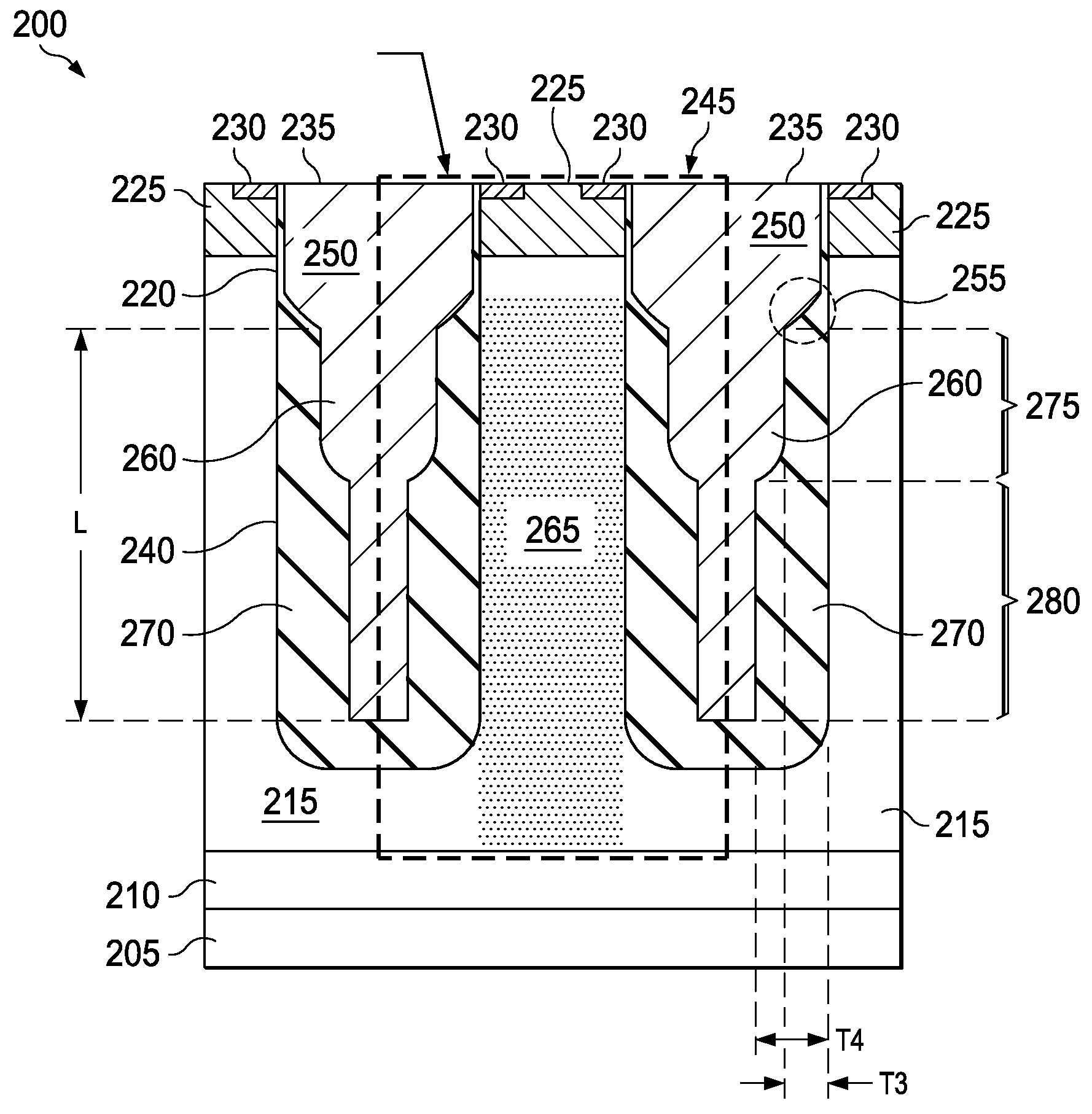

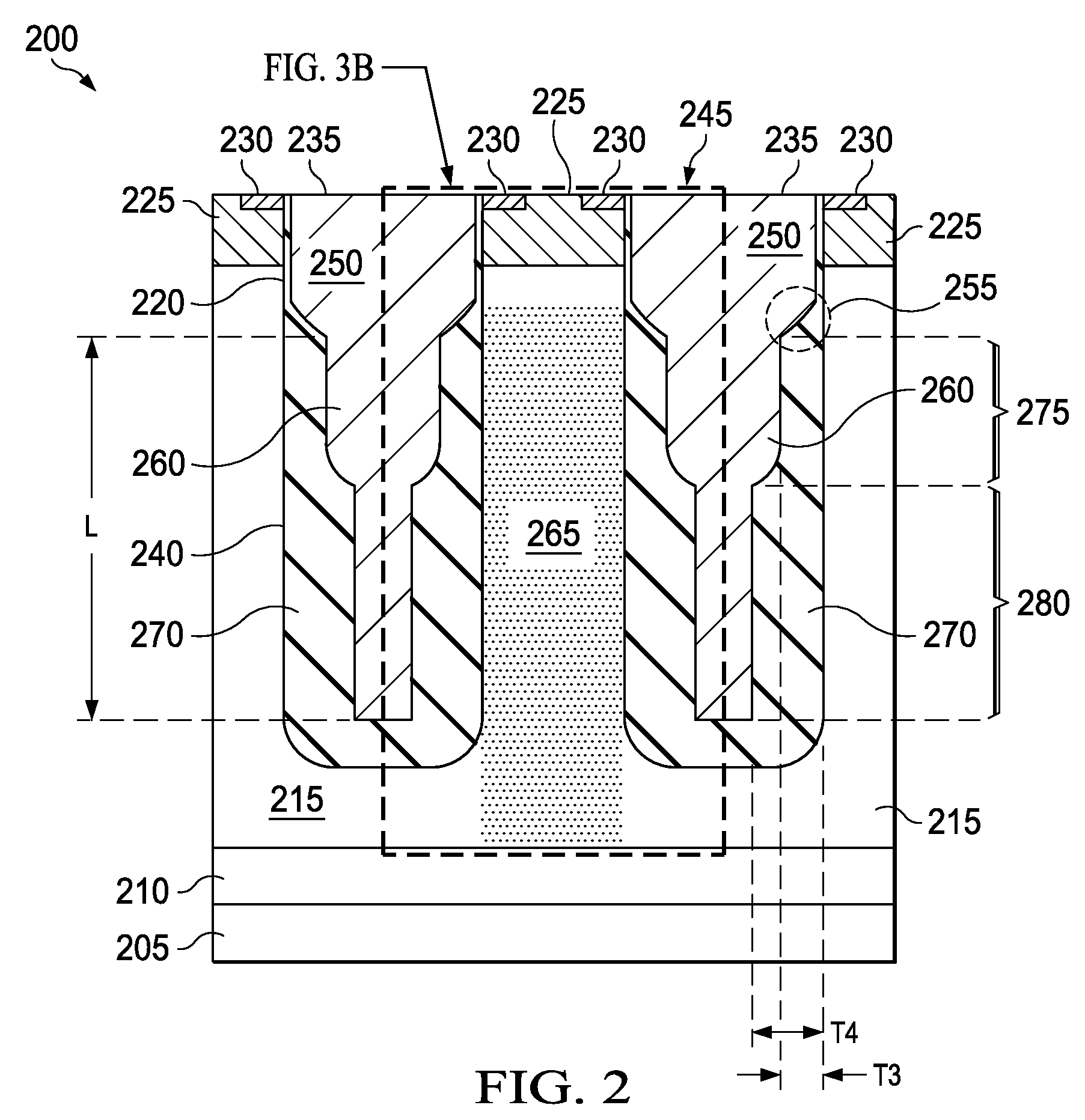

[0011]A trench field plate MOSFET includes a number of field plates formed within a drain extension region. The disclosure benefits from the recognition that operating characteristics of a trench field plate MOSFET may be improved by providing a dielectric between the field plates and the drain extension region that has a variable thickness therebetween. The variable thickness is expected to provide a flatter potential distribution in the direction of carrier flow during operation, resulting in increased blocking voltage, e.g.

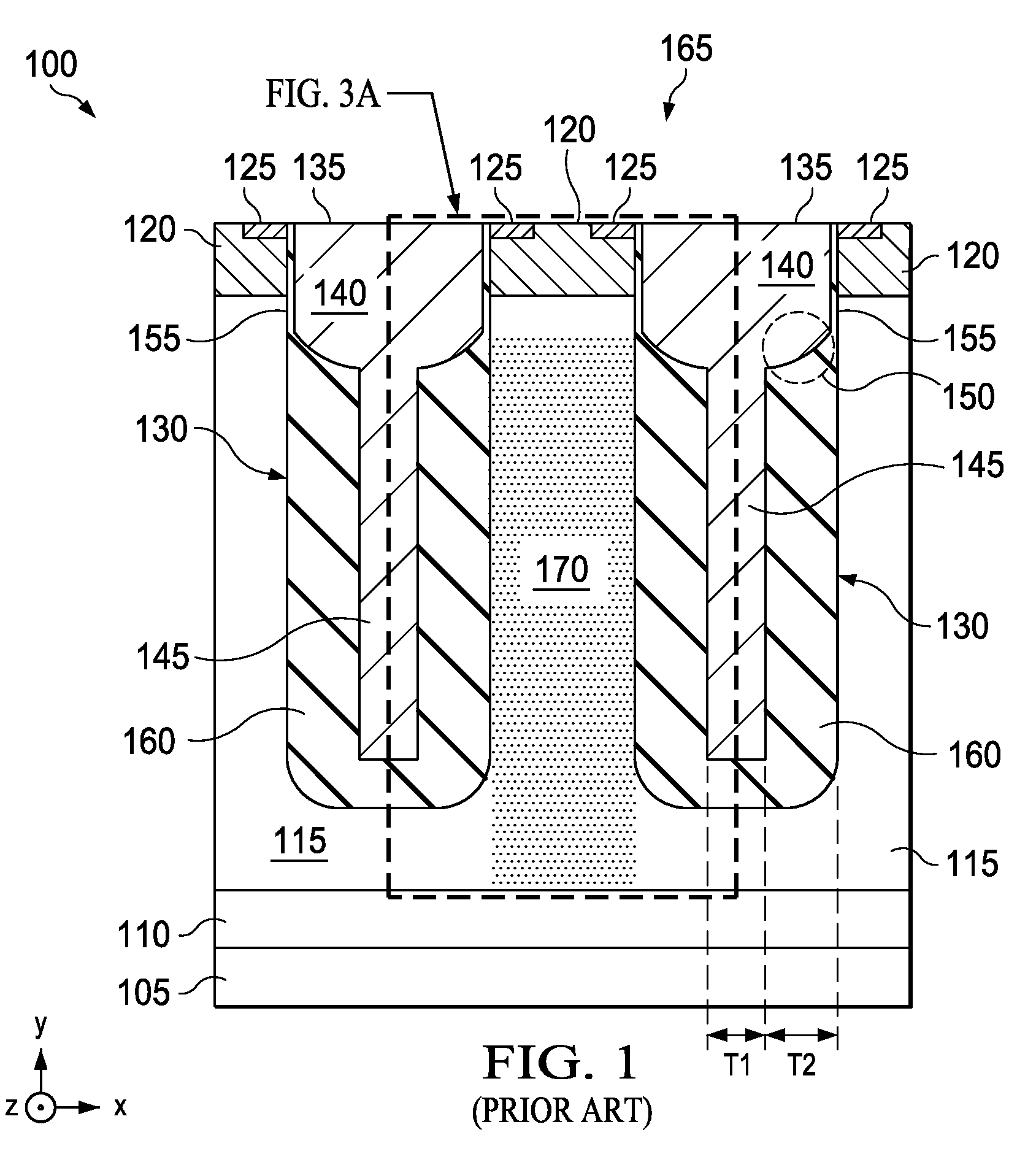

[0012]FIG. 1 illustrates a portion of a prior art trench field plate power MOSFET 100 (hereinafter referred to as the MOSFET 100). Coordinate axes are shown for reference. The illustrated portion includes a substrate 105 with a drain 110 and a drain extension 115 located thereover. A body 120 (sometimes referred to as a backgate) is located over the extension 115, with a source 125 formed over the body 120. The drain 110, the extension 115 and the source 125 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com