Tailored profile pedestal for thermo-elastically stable cooling or heating of substrates

a technology of thermo-elastically stable cooling or heating of substrates, applied in the direction of indirect heat exchangers, lighting and heating apparatus, machine operation modes, etc., can solve the problems of large thermal distortion of substrates, increased doming or unstable doming response, unstable thermo-elastic response, etc., to eliminate unstable wafer distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

[0036]In describing the preferred embodiment of the present invention, reference will be made herein to FIGS. 1-12 of the drawings in which like numerals refer to like features of the invention.

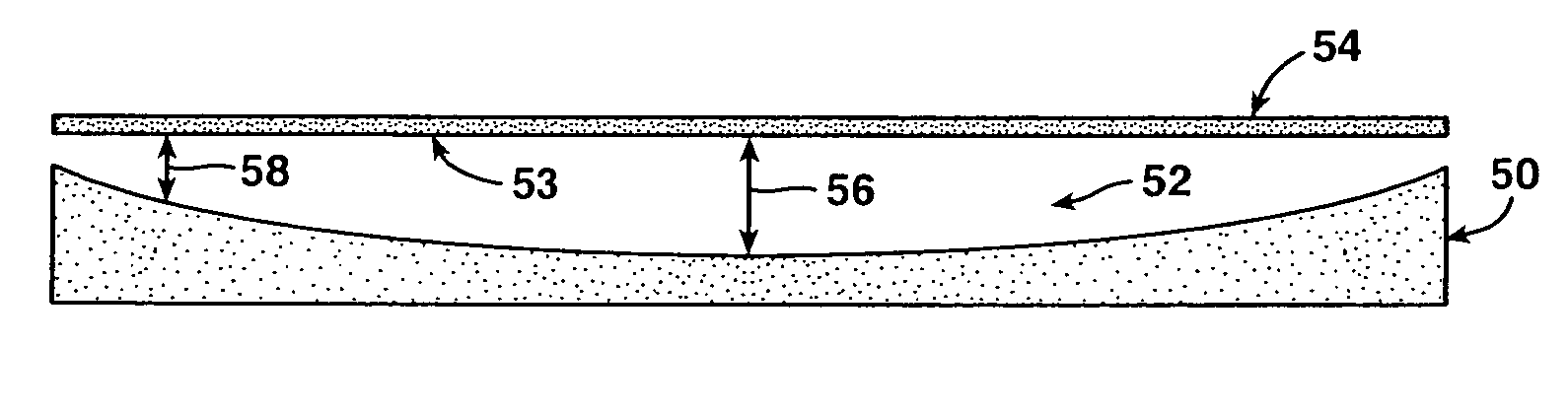

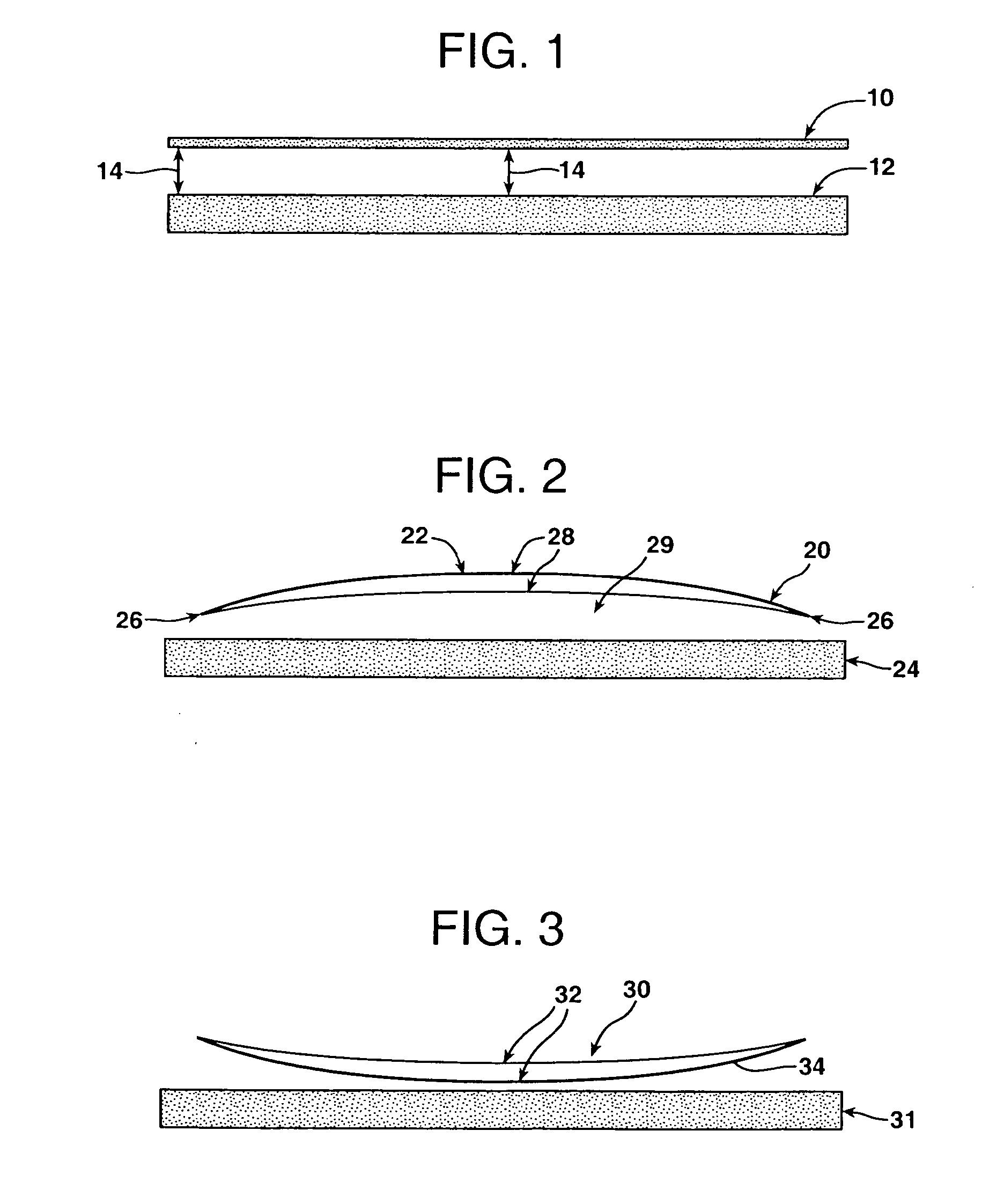

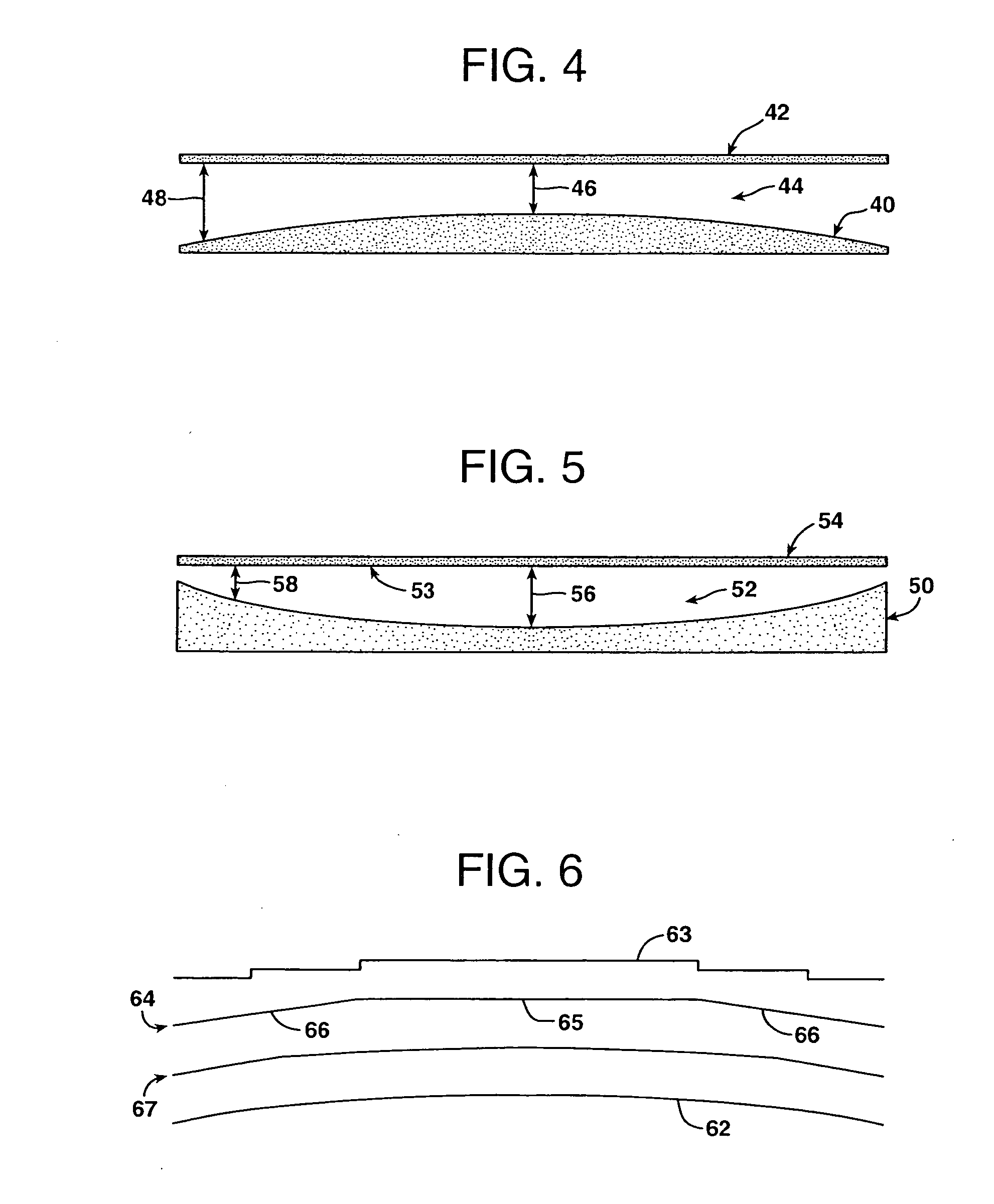

[0037]Two embodiments are presented to eliminate unstable wafer distortion during wafer heating or cooling, minimize wafer cracking, and promote thermo-elastically stable wafer cooling and heating. One embodiment is directed to domed wafers during wafer cooling, and the other is directed to cupped wafers during wafer heating. The embodiments modify the surface of the cooling and heating devices, and benefit from the geometric differences between the cooling or heating device surface and the adjacent wafer surface.

[0038]FIG. 4 depicts the gap 44 between a convex-shaped cooling device 40 and a flat substrate 42. The gap 44 is shown increasing from the substrate center 46 to the substrate edges 48 by virtue of the shaped cooling device surface. Combined with a gas introduced as a conductive med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com