Water conserving toilet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

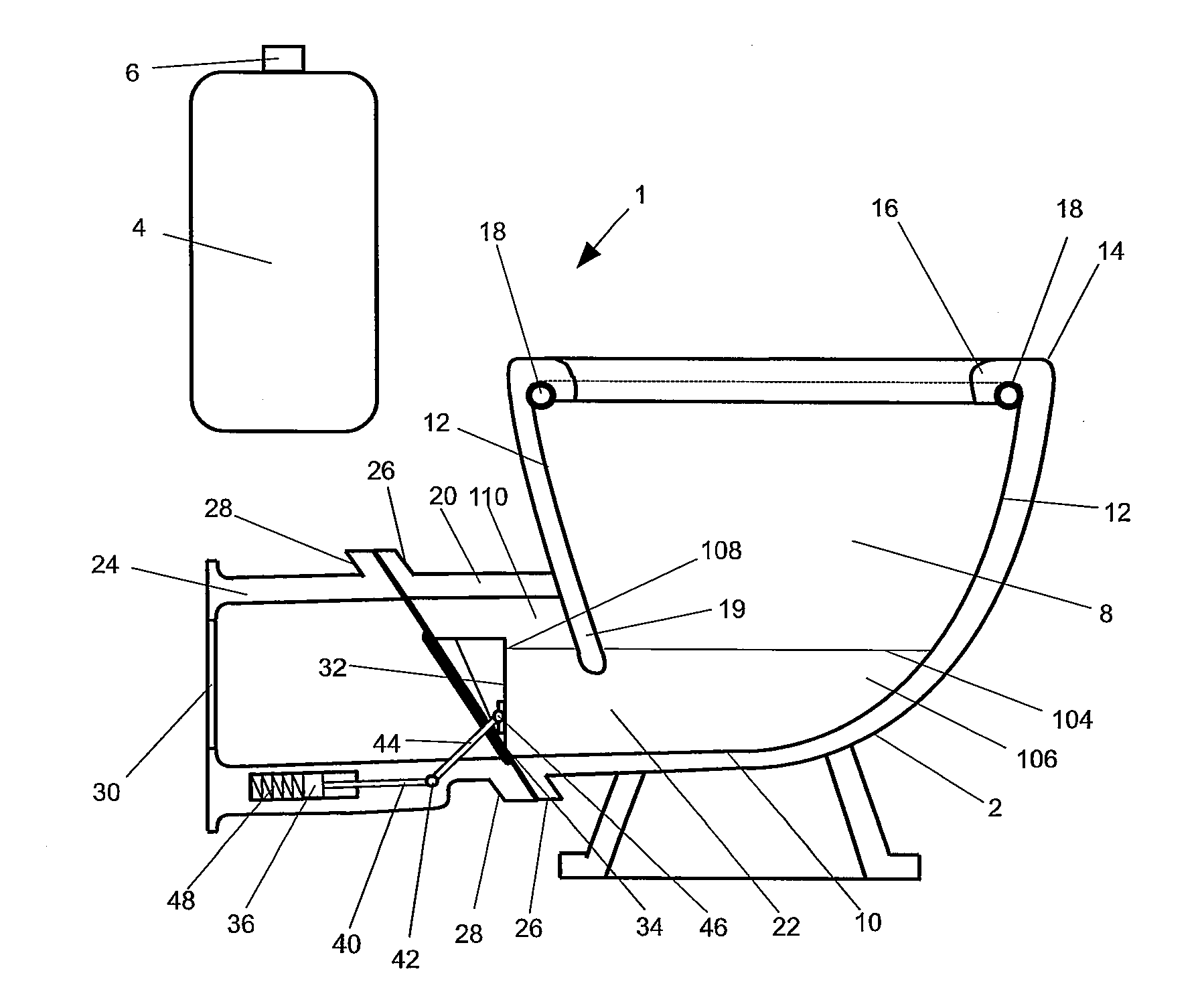

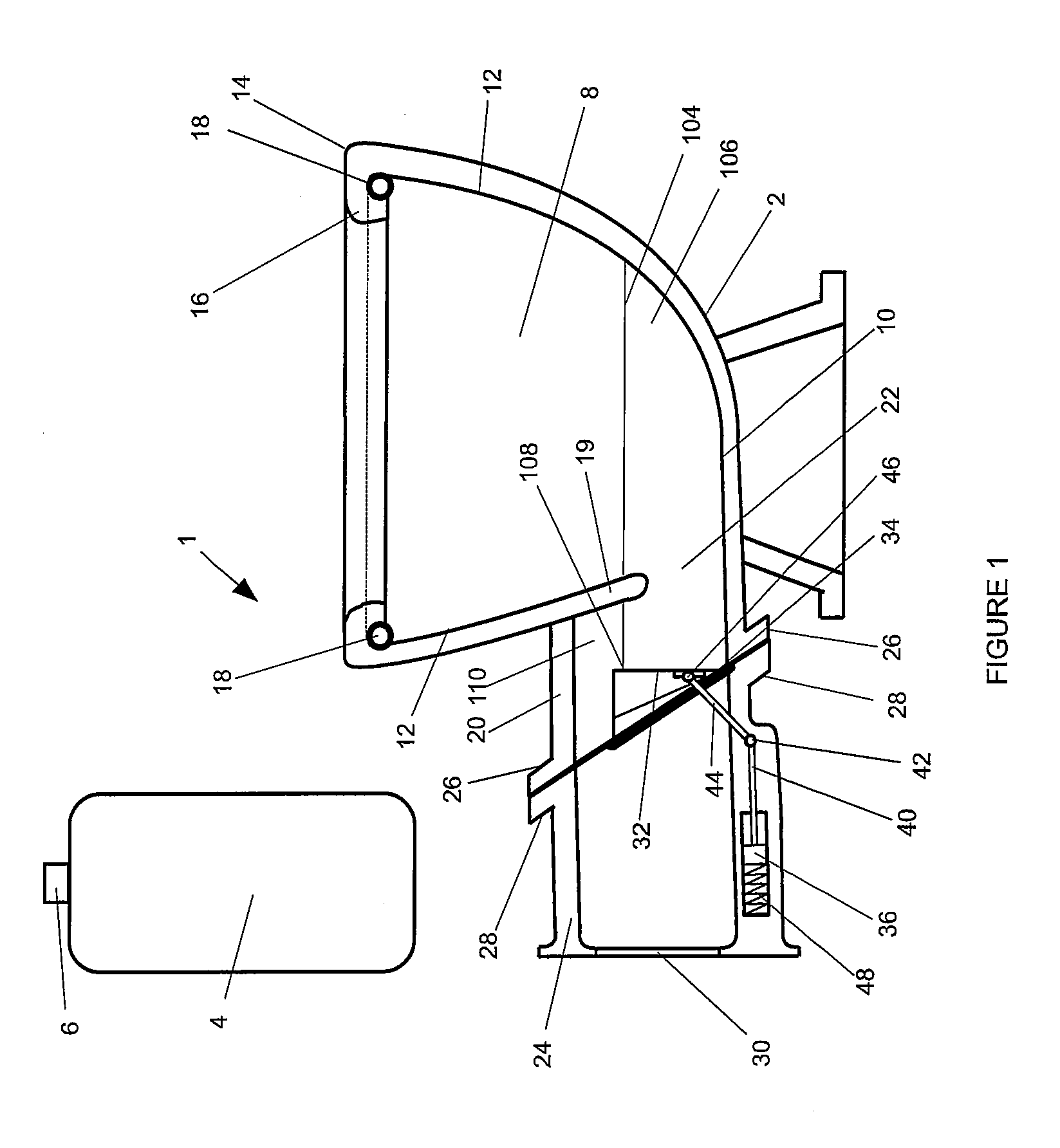

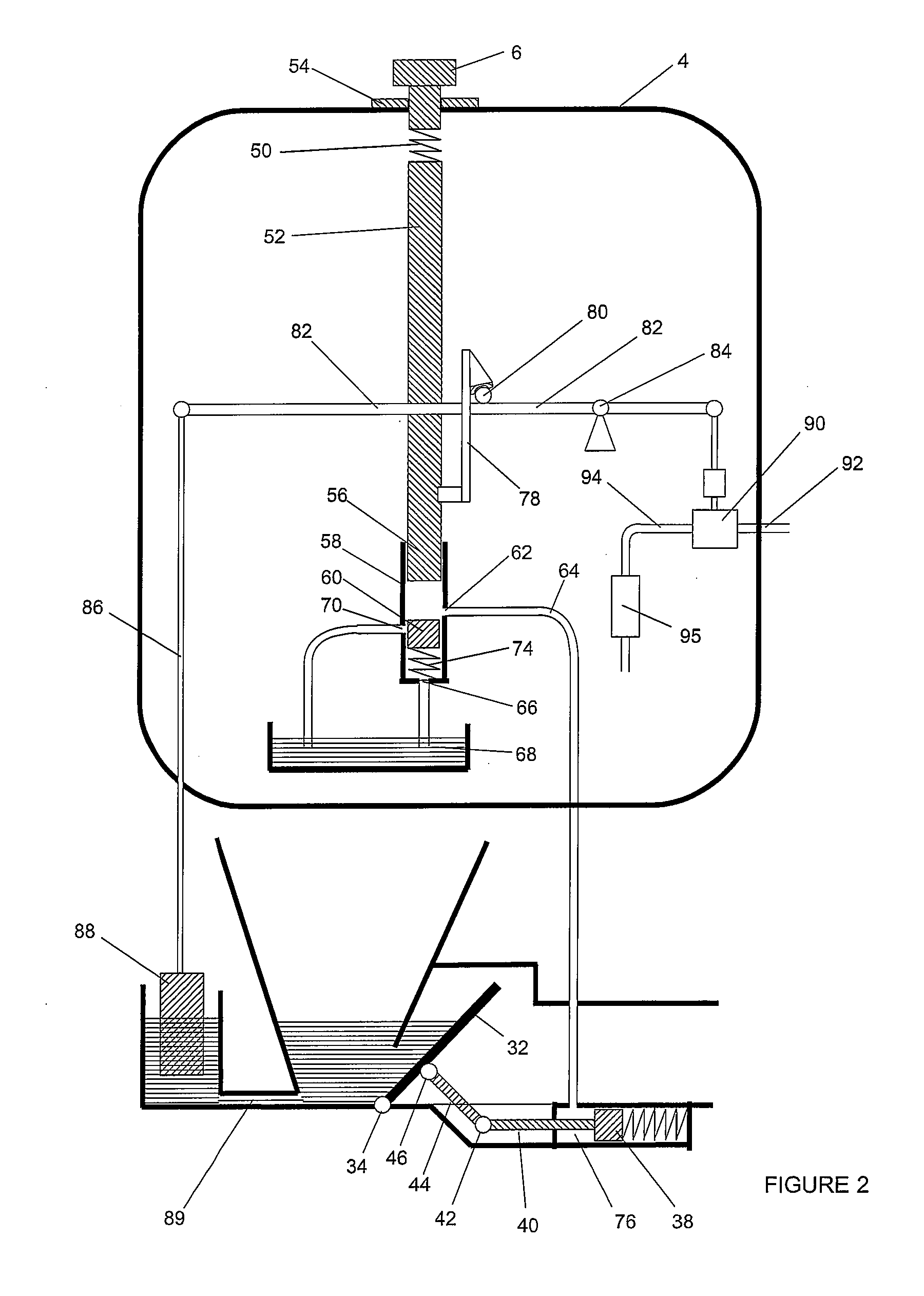

[0053]With reference to FIG. 1, a toilet 1 comprises a ceramic unit 2 and rear housing 4, which has a manually operable flush button 6 (functioning as the flush control) mounted thereon, and encloses the majority of a flush control mechanism which is described further below. The ceramic unit is shaped to define a toilet bowl 8 having an interior base 10, interior wall 12 and rim 14 with an overhanging peripheral lip 16 which lip retains a spray ring 18, the spray ring being formed from an injection moulded plastics material and comprising a plurality of apertures (not shown).

[0054]The interior wall of the ceramic unit includes a baffle 19 (functioning as the divider) which separates the toilet bowl from a first pipe section 20. An aperture 22 extends under the baffle into the first pipe section to allow the passage of water and solids from the toilet bowl into the first pipe section in use. The first pipe section is sealedly attached to a second pipe section 24 by cooperating flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com