Liquid tank, viewing device for under-liquid observation, and optical film

a technology for viewing devices and liquid tanks, applied in the direction of liquid/fluent solid measurement, instruments, optical elements, etc., can solve the problems of difficult removal of films, significant deterioration of viewing, and adhesion to films, and achieve easy cleaning, excellent visibility and durability, and reduced coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0079]The liquid tank of Embodiment 1 has a transparent wall, and on the internal surface of the wall, a first moth-eye layer having a moth-eye structure and a protective layer covering the moth-eye structure are disposed in this order from the wall side.

[0080]Inside the tank of the present Embodiment, a material containing at least a liquid is stored. An observer views the content of the tank, such as under-liquid objects (e.g., living creatures), the liquid level, the liquid itself from the outside through the transparent wall. Thus, the tank of the present Embodiment is suitably used as an aquarium or observation tank, including a water tank and a tank with a viewing window.

[0081]According to the tank of the present Embodiment, the first moth-eye layer having a moth-eye structure allows markedly reducing light reflection on the interface between the first moth-eye layer and the protective layer (e.g., a reflectance of 0.1% or lower). The transparent wall and the liquid (hereinaft...

embodiment 2

[0119]The viewing device for under-liquid observation of Embodiment 2 includes a transparent window, and on the external surface of the window, a first moth-eye layer having a moth-eye structure and a protective layer covering the moth-eye structure are disposed in this order from the window side.

[0120]The external surface of the transparent window means a surface on the side opposite to the observer side.

[0121]Thus, in Embodiment 2, the first moth-eye layer and the protective layer mentioned in Embodiment 1 are applied to a viewing device for under-liquid observation. Embodiment 2 is mentioned below mainly with reference to embodiments and effects different from those in Embodiment 1, and the same contents are omitted.

[0122]The viewing device of the present Embodiment is used with at least the transparent window being in contact with liquid. Through this transparent window, the observer views under-liquid objects.

[0123]The viewing device of the present Embodiment includes the first...

example 1

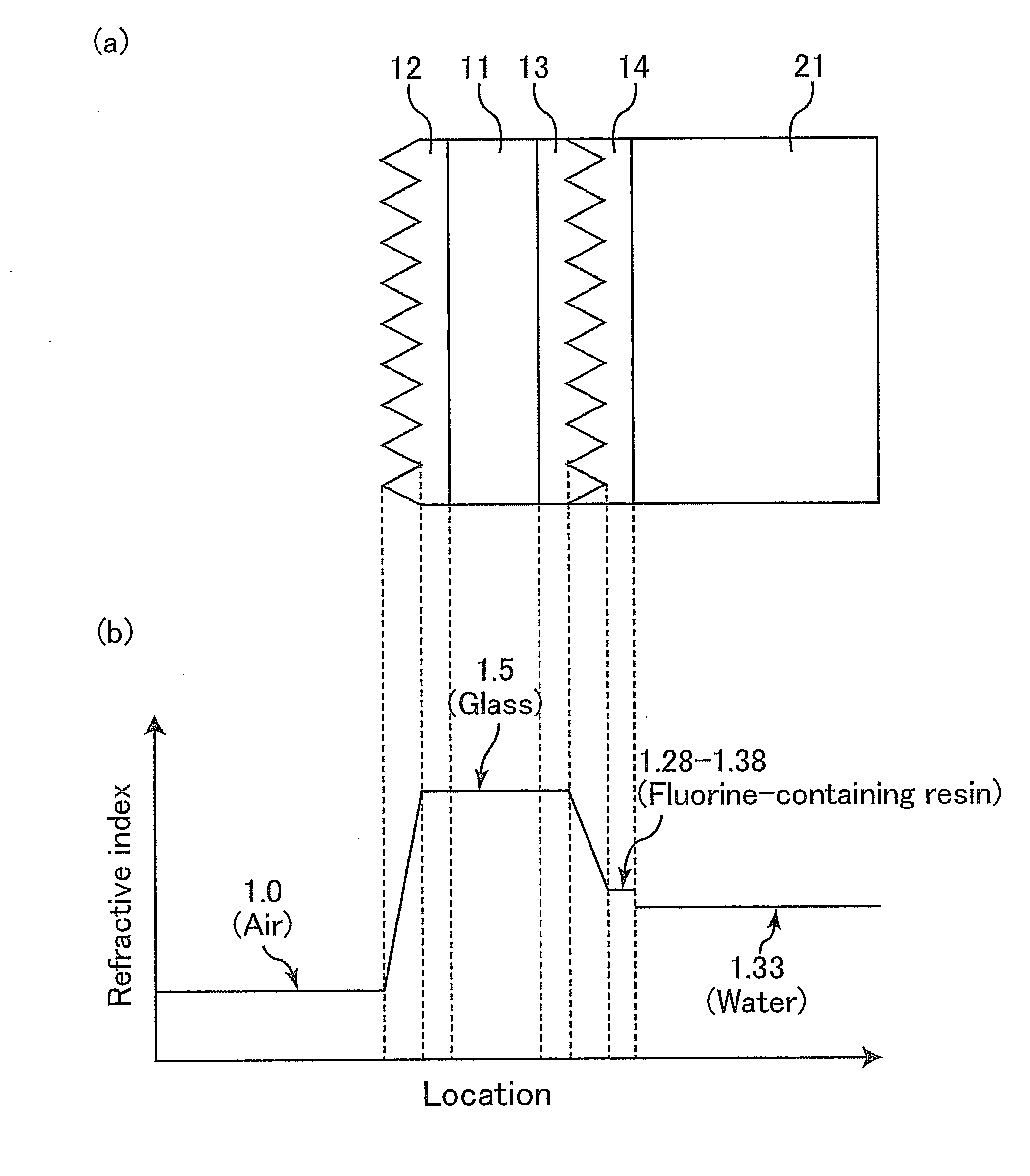

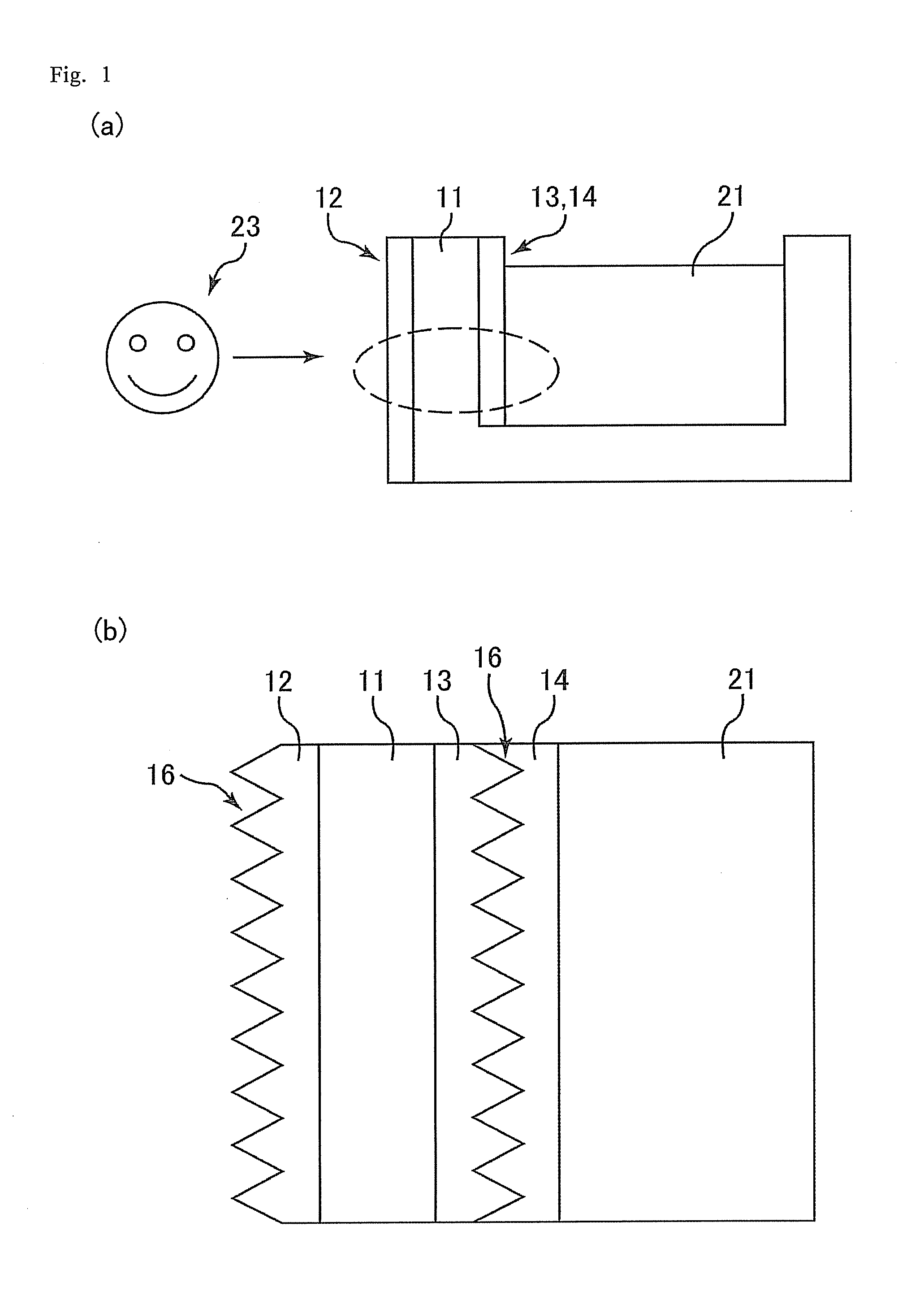

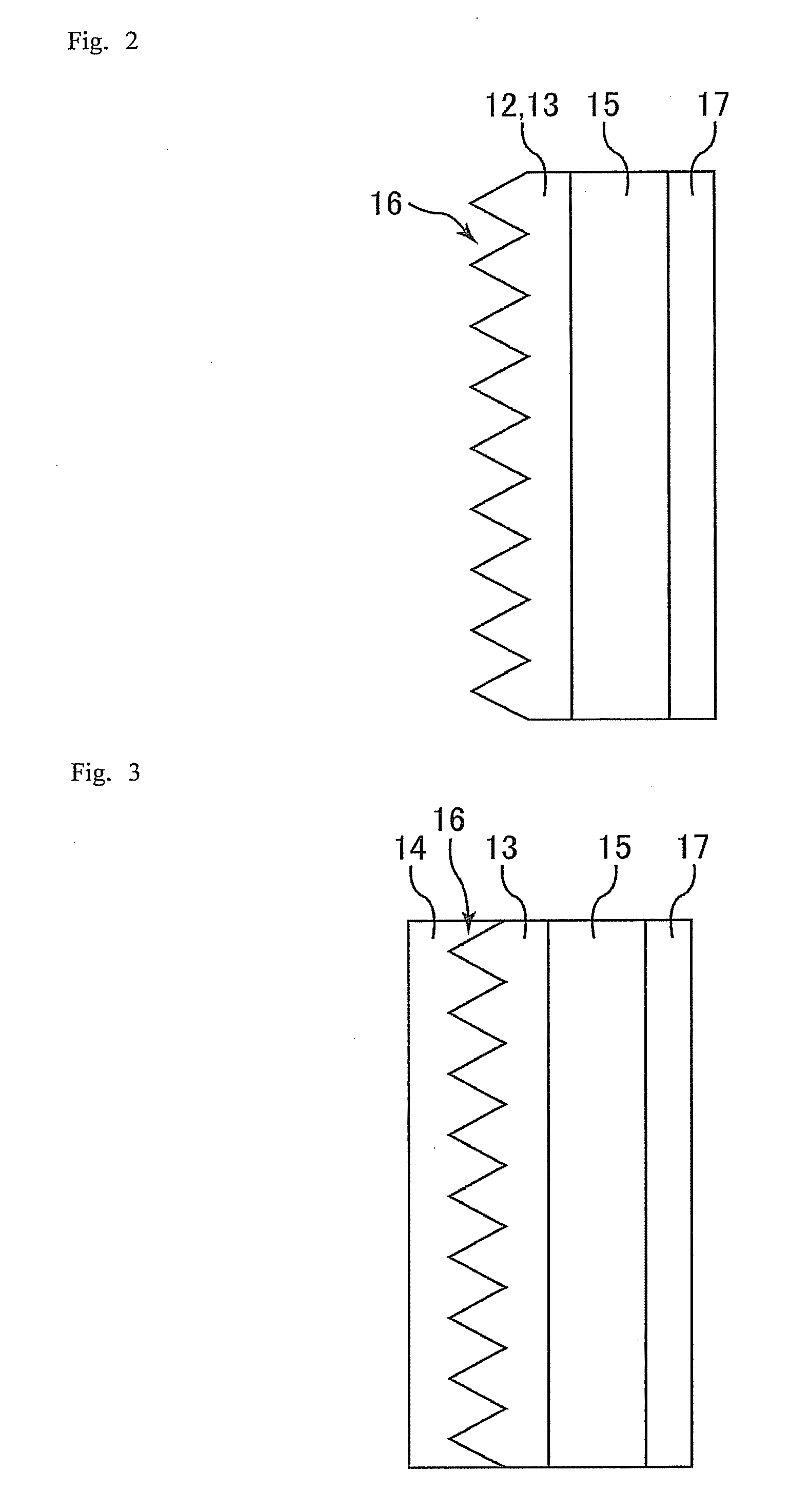

[0151]FIG. 1 is a schematic view showing a liquid tank of Example 1. FIG. 1(a) is an overall cross-sectional view of the tank. FIG. 1(b) is an enlarged view of a region (side surface) surrounded by the broken line of FIG. 1(a). FIG. 2 is a cross-sectional view schematically showing a moth-eye layer of the liquid tank of Example 1. FIG. 3 is a cross-sectional view schematically showing the moth-eye layer and a protective layer in the liquid tank of Example 1.

[0152]The present Example relates to an embodiment in which the liquid tank of the present invention is used as a water tank. The water tank of the present Example has a multi-layer structure, as shown in FIG. 1, composed of: a transparent wall 11 constituting a container storing a content liquid, or water 21; a moth-eye layer (moth-eye film) 12 attached to the external surface (hereinafter, also referred to as an “A surface”) of the transparent wall 11, which faces an observer 23; a moth-eye layer (moth-eye film) 13 attached to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com