Road maintenance method and vehicle

a technology for road maintenance and vehicles, applied in the direction of in situ paving, roads, construction, etc., can solve the problems of insufficient uniform distribution of scrapped and cut materials, inability to easily adjust and inability to maintain the surface of roads. the effect of maintaining the stress on the cutting blade is within manageable limits and the height of cutting and smoothing blades is easy to adjus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

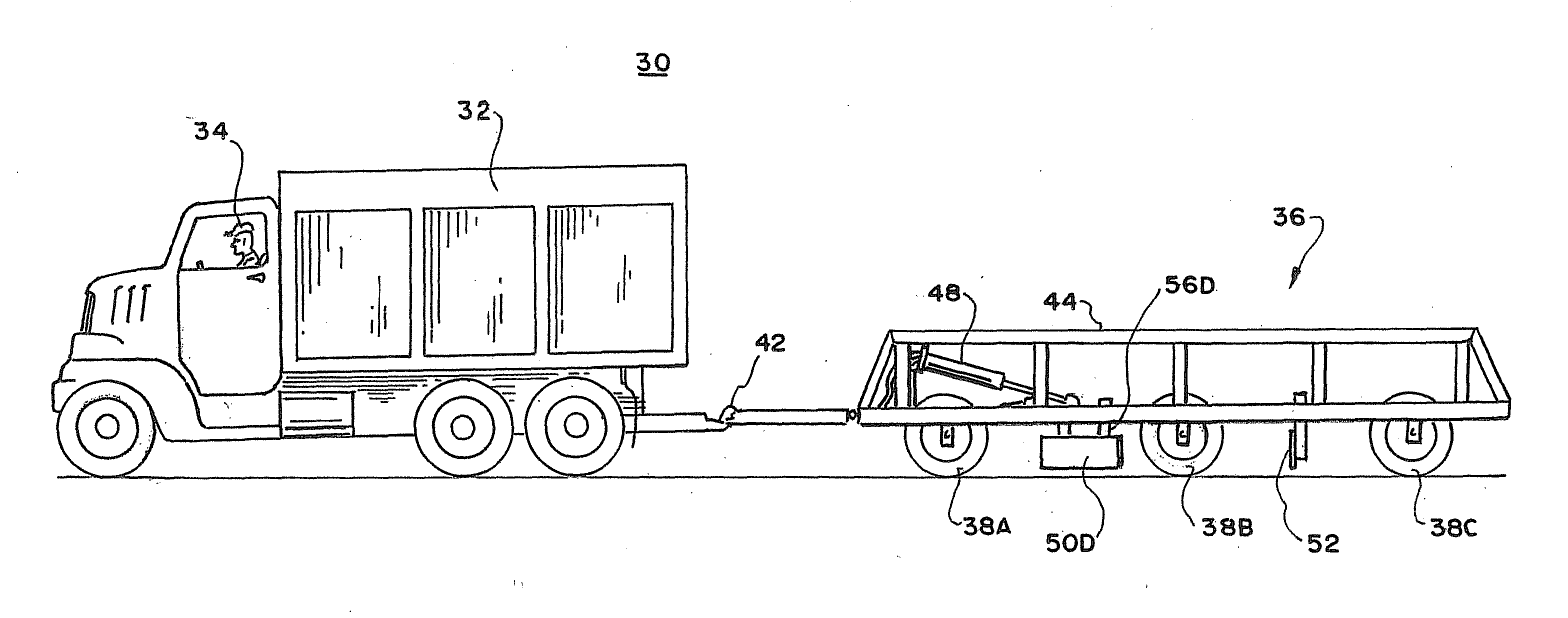

[0021]In FIG. 1 there is shown a flow diagram 10 of a process for using the road maintenance vehicle of this invention comprising the step 12 of determining relevant road surface condition, the step 14 of adjusting the cutting and smoothing blades, the step 16 of pulling the road maintenance vehicle at a fast relevant surface speed for the relevant road surface conditions and the tep 18 of pulling the road maintenance vehicle at a slow relevant speed. The step 14 of adjusting the blades for the relevant road surface conditions includes the step 24 of adjusting the height of the cutting blades within the blade-height wheel-averaging arrangement to keep the stress on the cutting blades within tolerances, the step 26 of adjusting the height of the smoothing blade to build a crown and smooth out ruts and holes, and the step 28 of adjusting the angle of the cutting blades to correspond to the length of the blades, road surface conditions, number of blades and height of the blades with re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com