Vapor chamber with separator

a technology of separator and vapor chamber, which is applied in the field of vapor chamber, can solve the problems that the prior vapor chamber structure still has some drawbacks in practical use, and achieve the effect of significantly boosting cooling performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]In cooperation with attached drawings, the technical contents and detailed description of the present invention are described thereinafter according to a preferable embodiment, not used to limit its executing scope. Any equivalent variation and modification made according to appended claims is all covered by the claims claimed by the present invention.

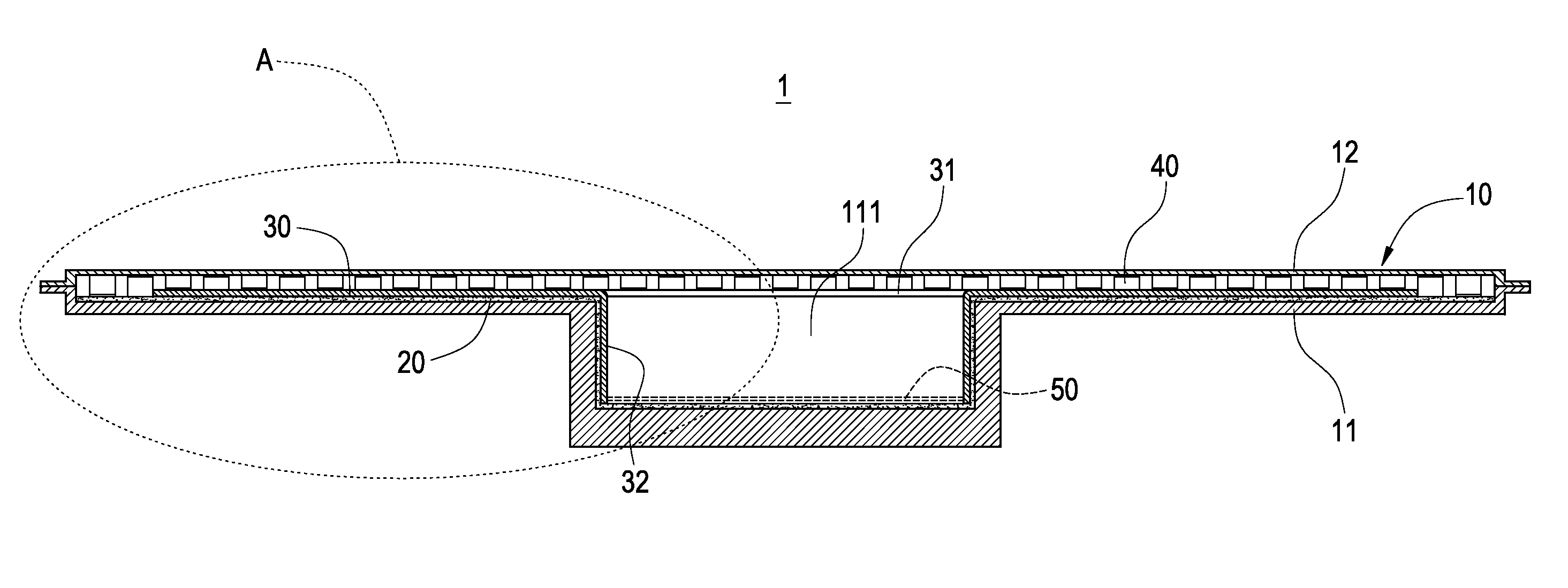

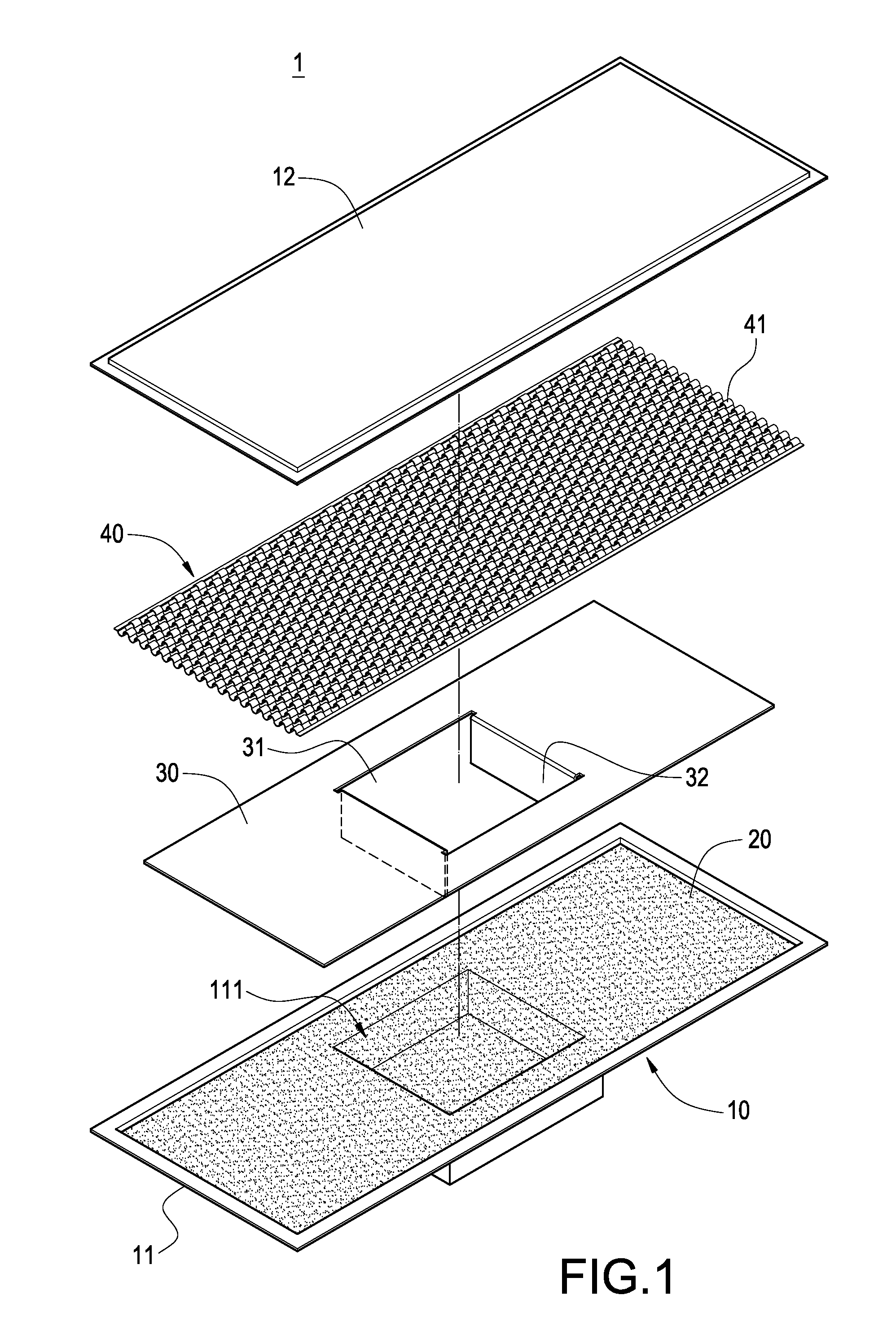

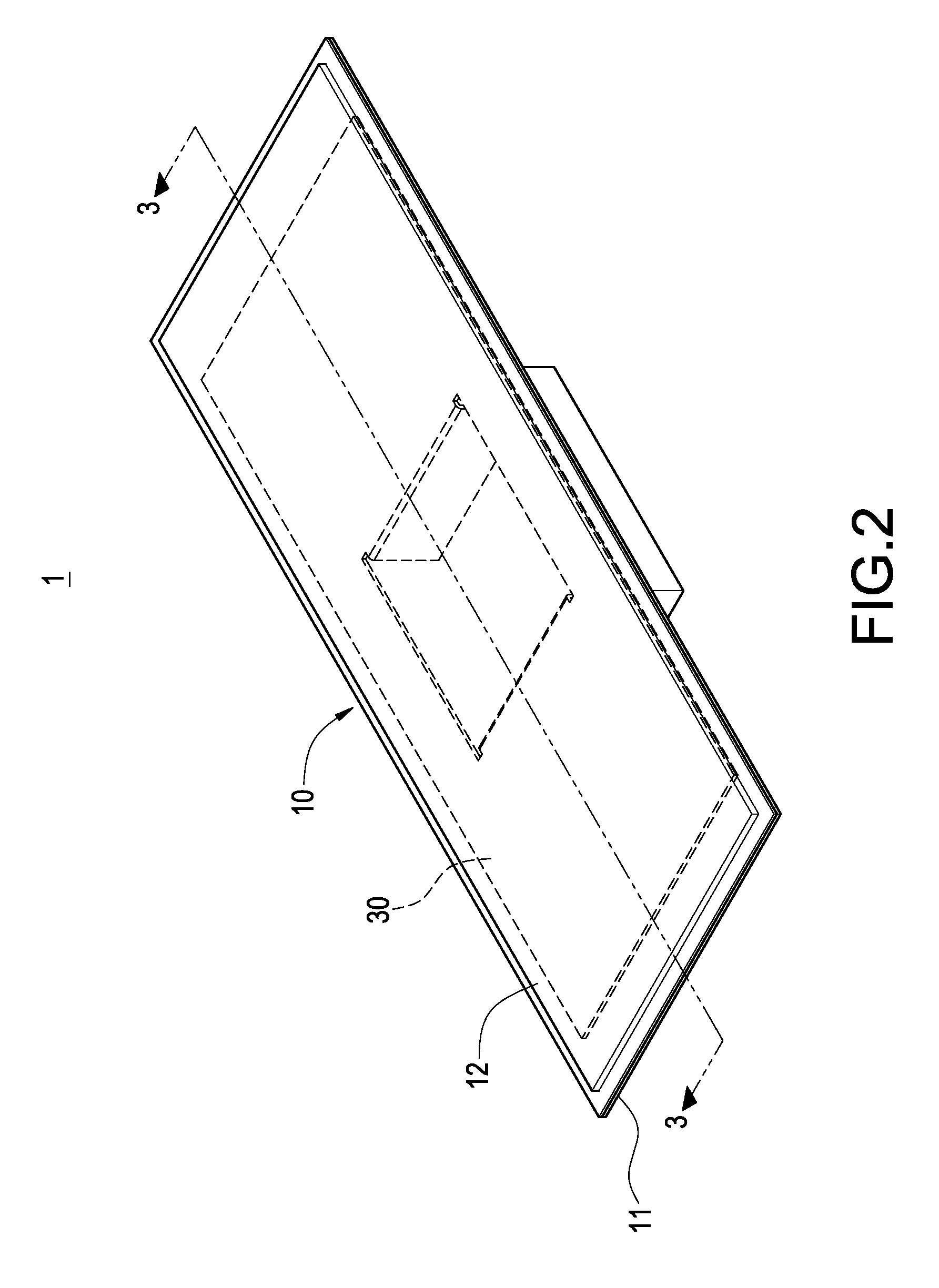

[0018]Please refer to FIG. 1 and FIG. 2, respectively showing a perspective explosive view and a perspective outer view of the invention. The invention is to provide a vapor chamber 1 with separator 30, including a shell 10, a capillary tissue 20, a separator 30, a supporting structure 40 and a working fluid 50 (referring to FIG. 4).

[0019]The shell 10 includes a lower shell plate 11 and an upper shell plate 12 sealing the lower shell plate 11. Partial section of the lower shell plate 11 is projected downwardly to form an accommodating room 111 therein. In this embodiment, the accommodating room 111 is shown as a rectangular confi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com