Arrangement for recooling cooling water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

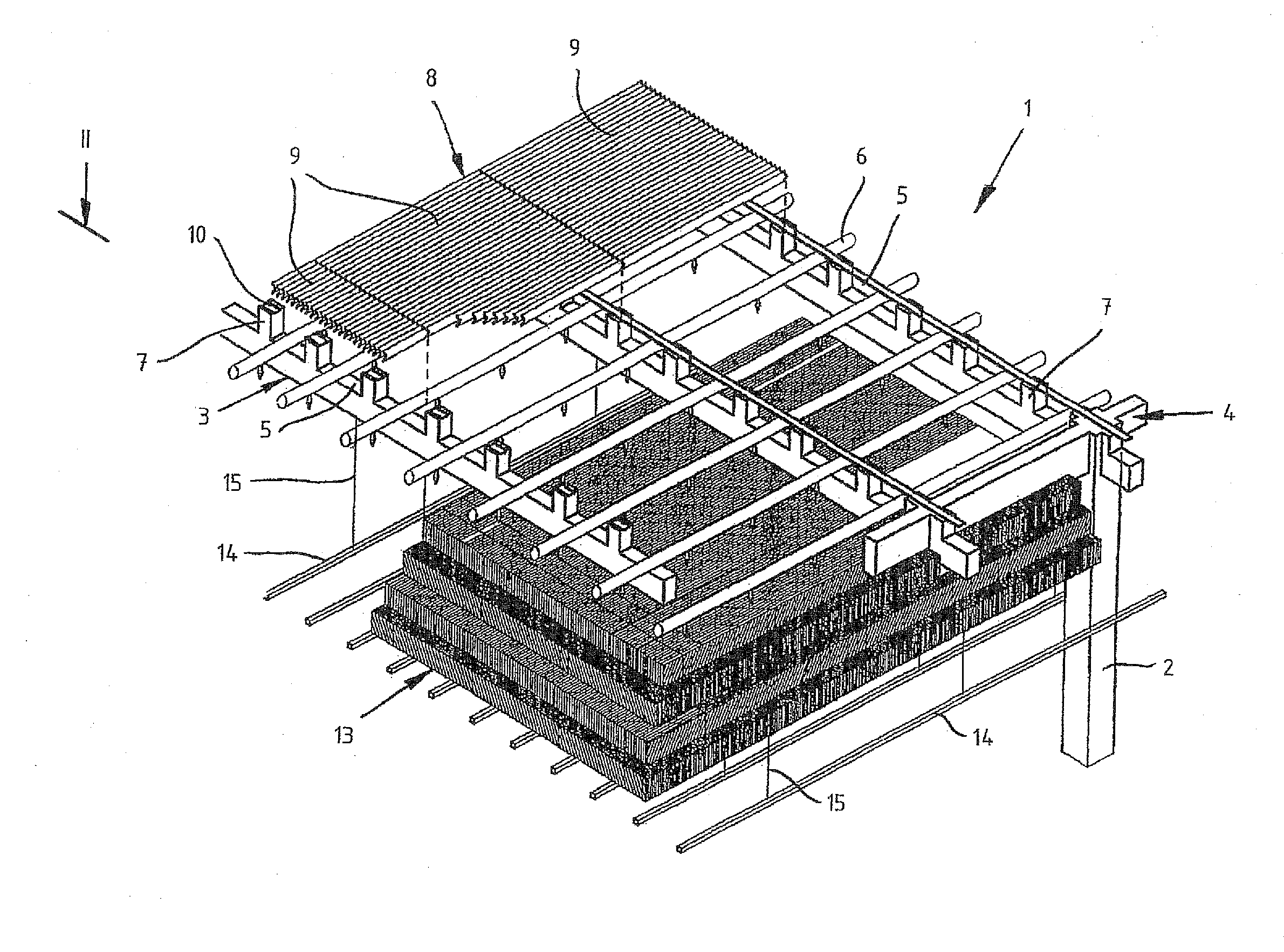

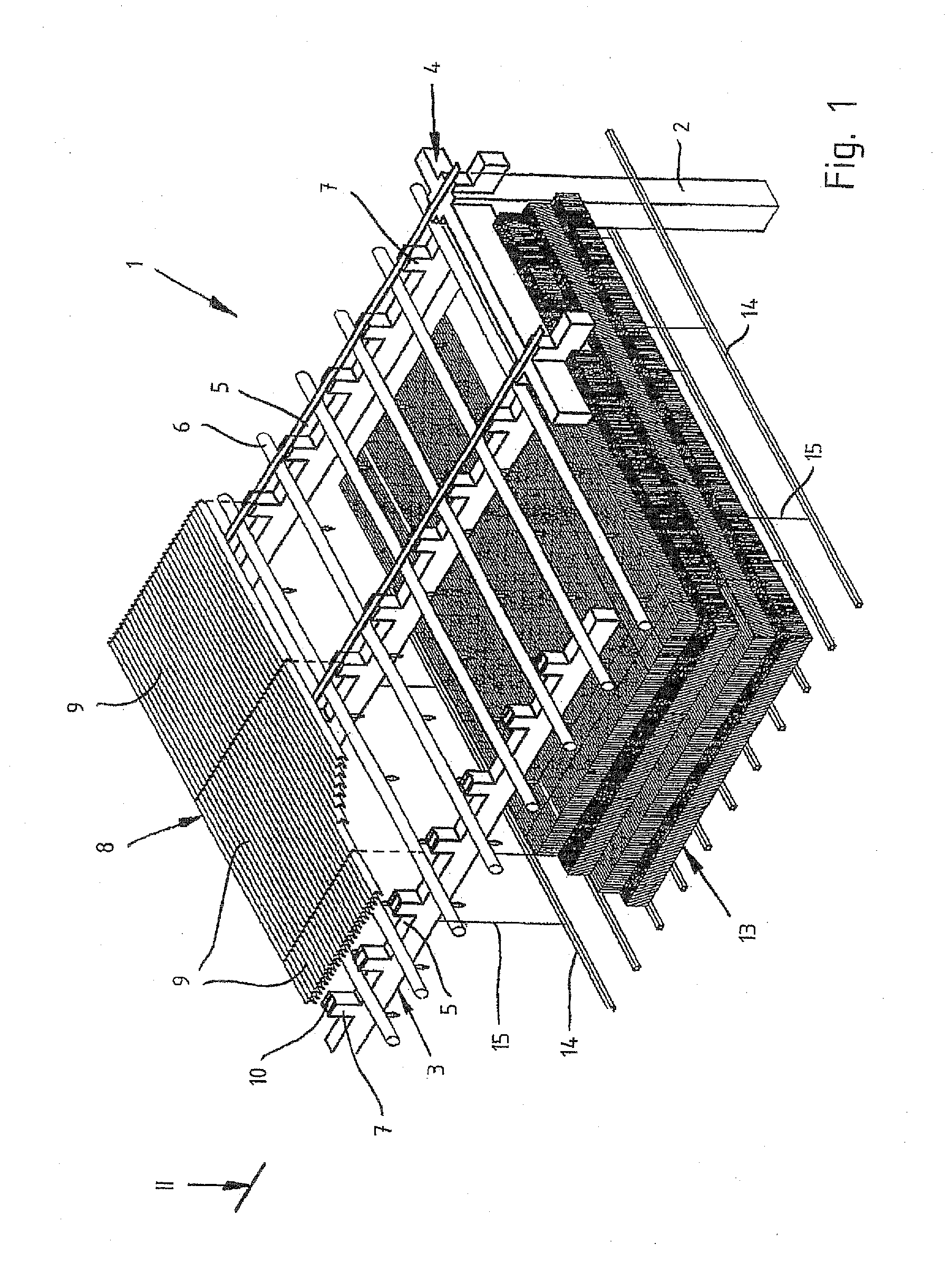

[0023]1 designates in FIG. 1 an arrangement for recooling of cooling water, as used in particular in a wet or hybrid cooling tower, not shown in greater detail, with natural ventilation or forced ventilation.

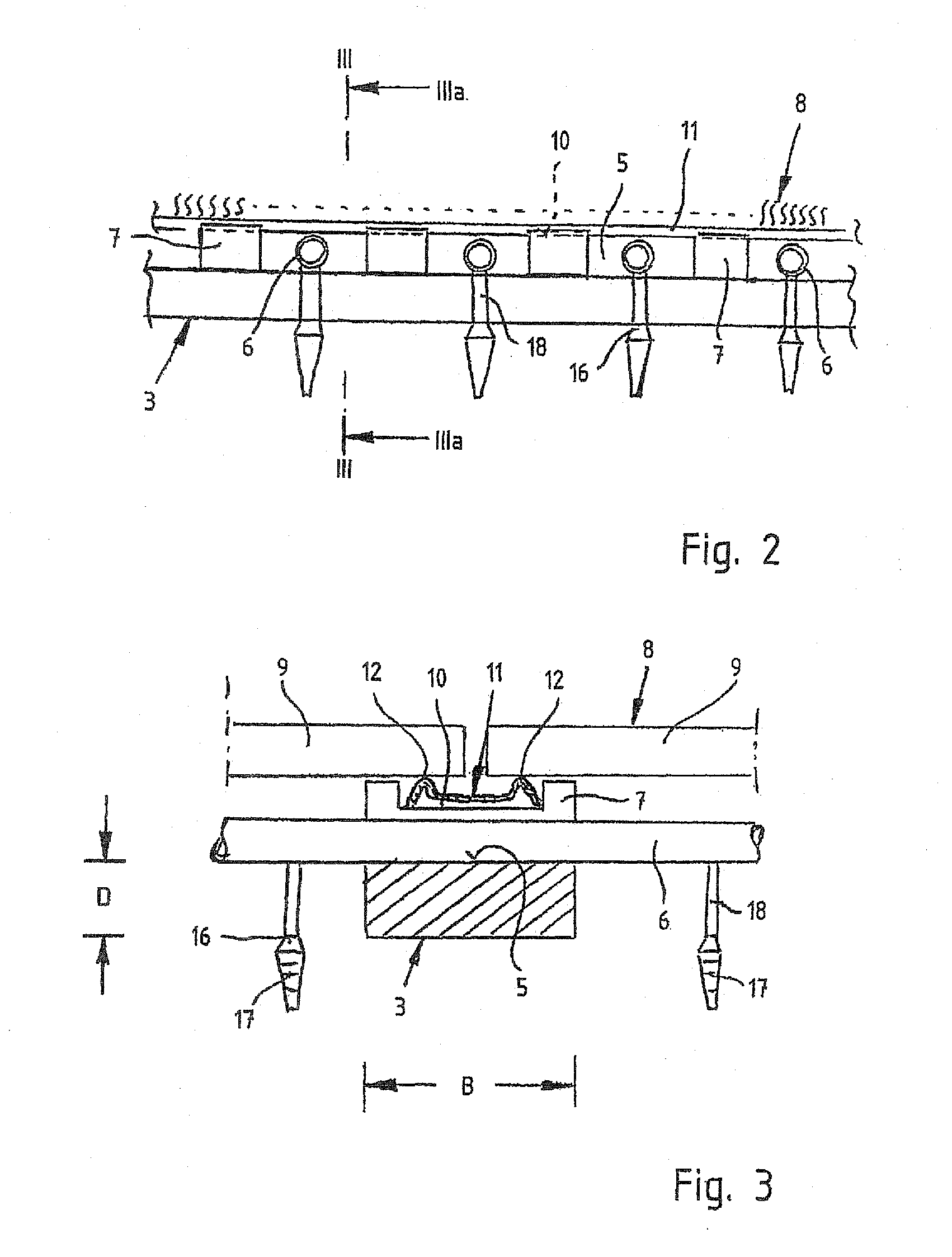

[0024]The arrangement 1 includes several vertical supports 2 as well as horizontal bars 3, 4 extending in longitudinal and transverse directions. The bars 3, as also shown in FIGS. 2 and 3, are provided with open-topped bearing points 5, which extend across their entire width B, for installation of distributor pipes 6 for cooling water to be recooled. Each two consecutive bearing points 5 in longitudinal direction of the bars 3 are separated from one another by a support 7 for mist collectors 8 which are provided above the distributor pipes 6. The mist collectors 8 are made of plastic sheets, curved in the vertical, and are subdivided into several surface segments 9. FIG. 1 involves an exploded view which depicts the mist collectors 8 at a distance to the supports 7. The broken ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com