Cable Transport Device

a technology of transport device and cable, which is applied in the direction of electrical equipment, thin material processing, line/current collector details, etc., can solve the problems of cable threading, cable replacement, and complicated design of force transmission through a plurality of axes of rotation, so as to ensure the necessary precision of cable processing and simplify the design of the cable transport device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

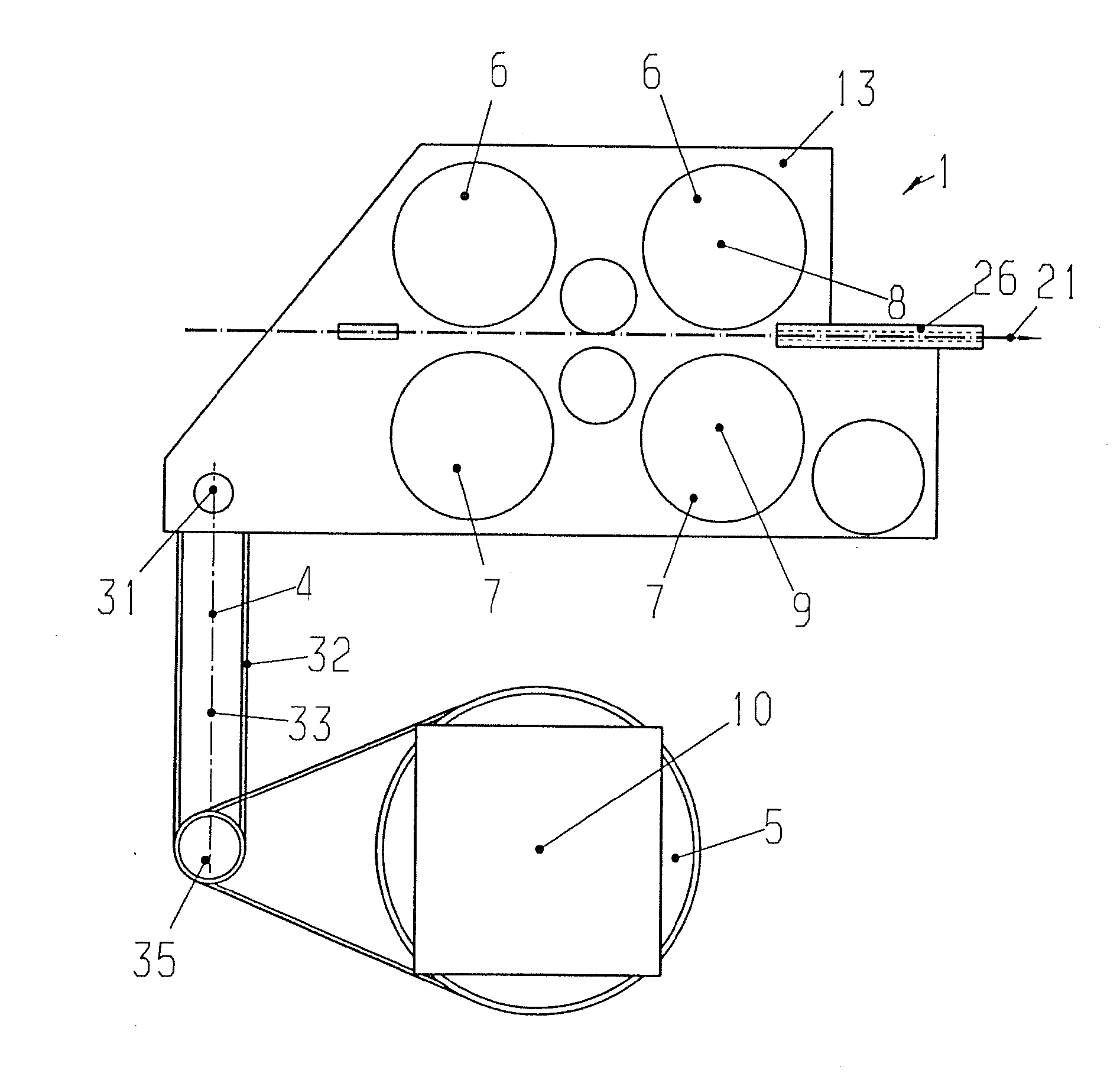

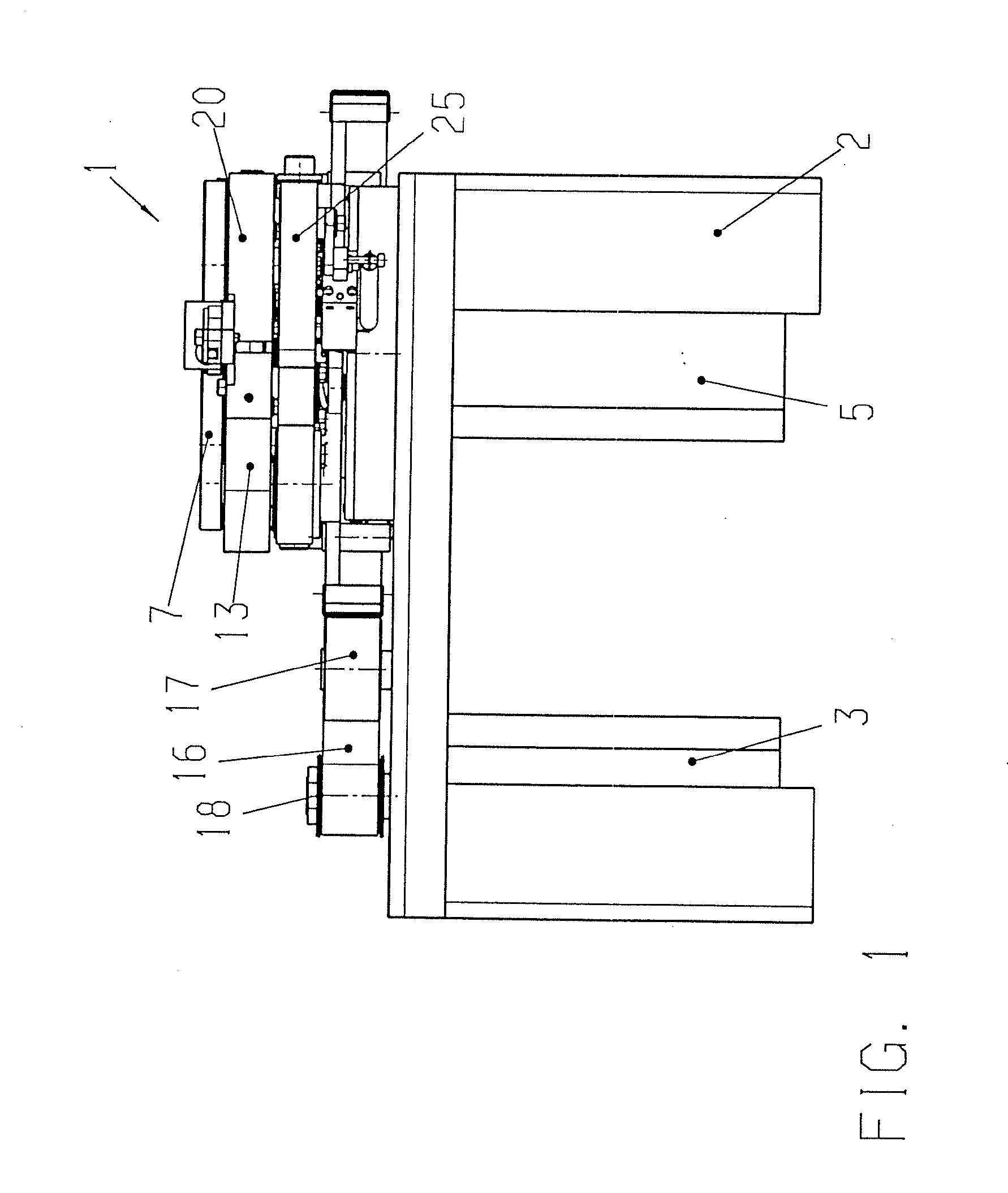

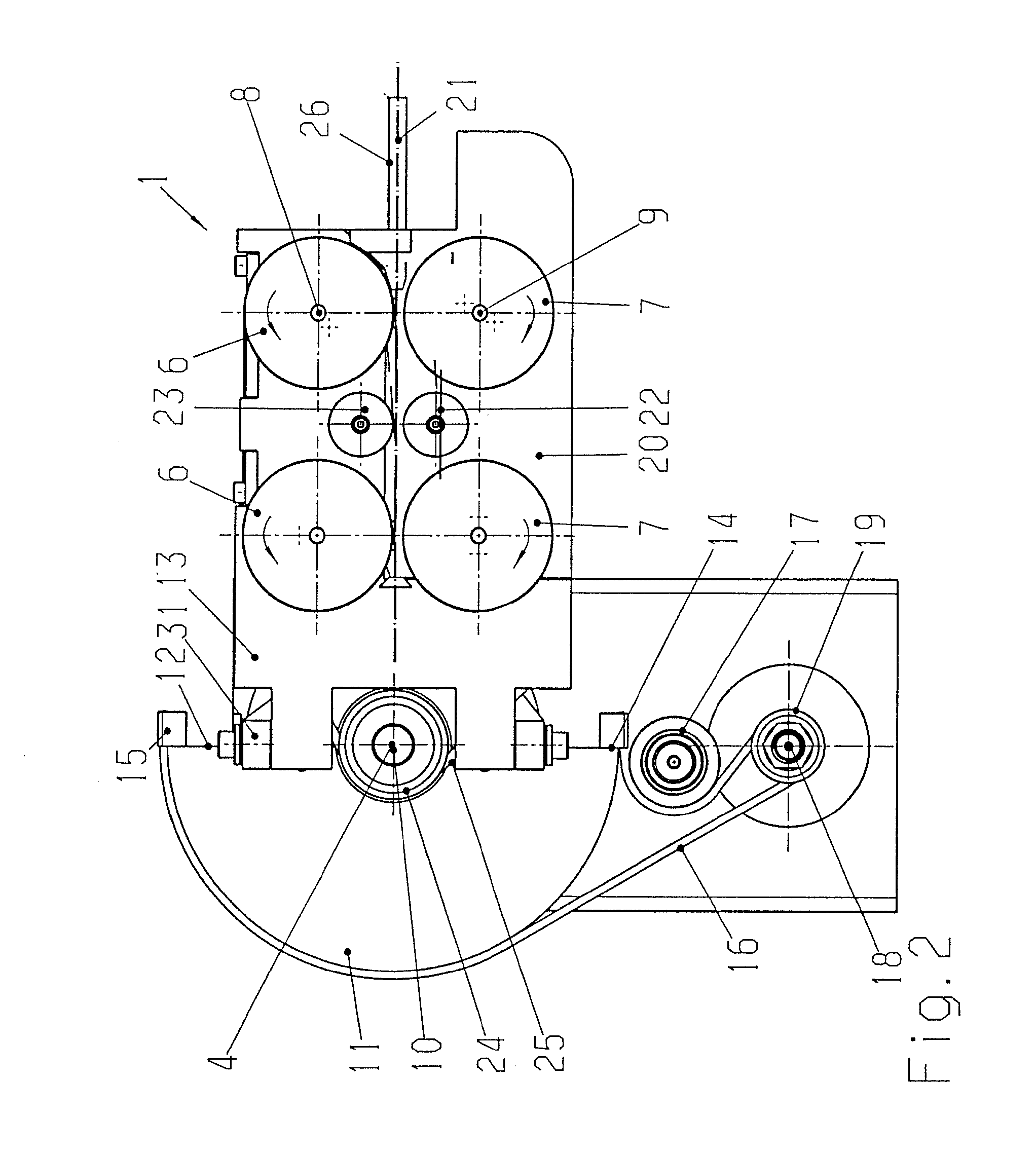

[0026]The cable transport device according to FIGS. 1, 2 and 6 has a pivotably mounted cable transporter 1 for a cable 21 to be drawn in and to be transported, and a first drive means 3 connected in a stationary manner to a base frame 2 and intended for achieving an exactly defined pivot movement of the cable transporter 1 about a pivot axis 4. A second drive means 5 ensures synchronous driving of two cooperating pressure rollers 6 with two cooperating pressure rollers 7, whose axes 8, 9 of rotation are parallel to one another and parallel to the common pivot axis 4. The two pressure rollers 7 are, as shown in FIG. 2, arranged so as to be laterally adjustable.

[0027]According to the invention, the second drive means 5 with its drive axle 10 is connected in a stationary manner to the base frame 2. The drive axle 10 of the second drive means 5 for the pressure rollers 6, 7 of the cable transporter 1, coincides with the pivot axis 4 for the cable transporter 1.

[0028]In the embodiments o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com