Drain assembly, drain body for use in such an assembly and method for building-in of a drain

a technology of drain body and drain, which is applied in the direction of sewerage structure, sewer system, domestic plumbing, etc., can solve the problem of watertight connection between the drain and the tiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

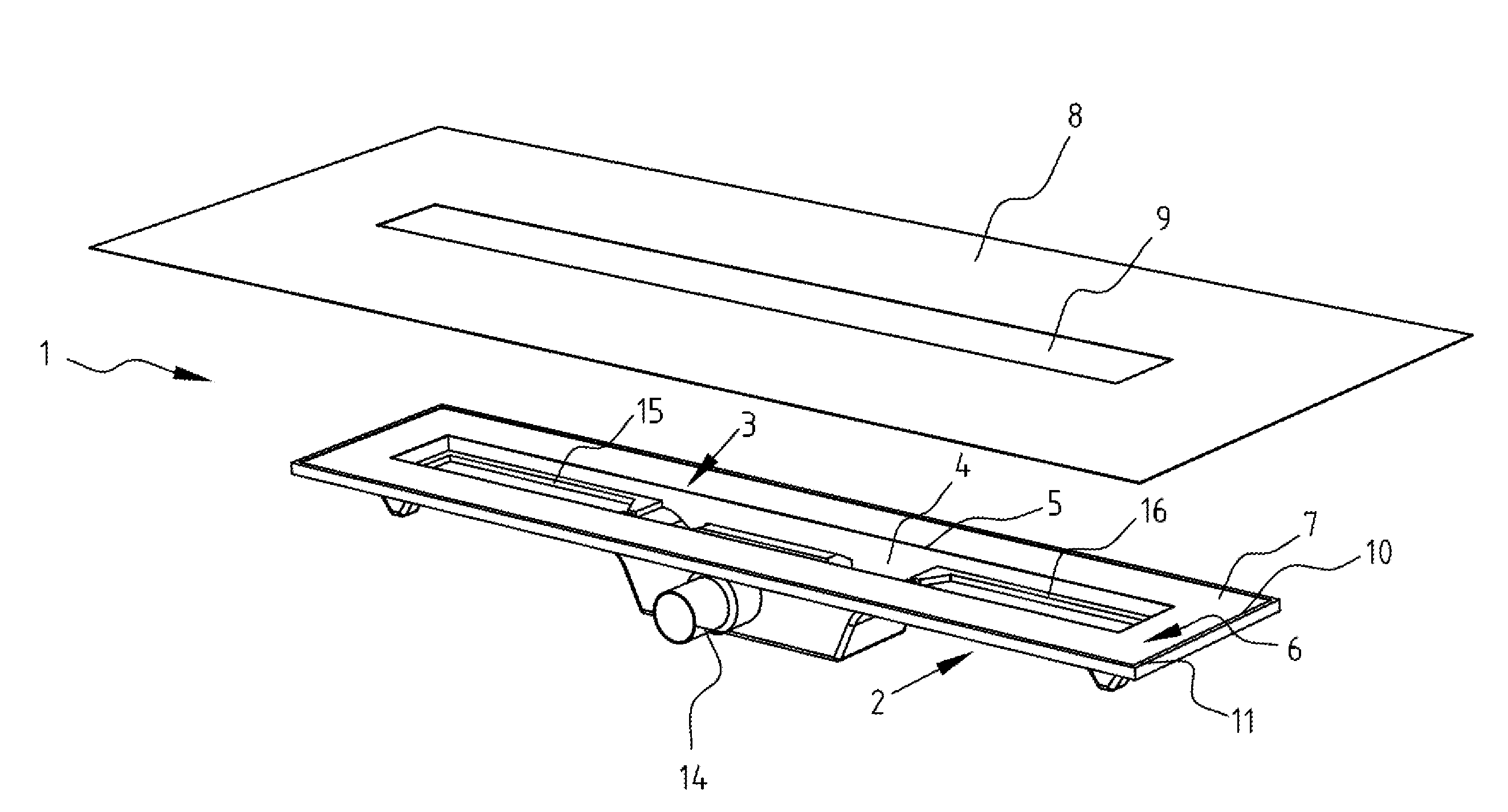

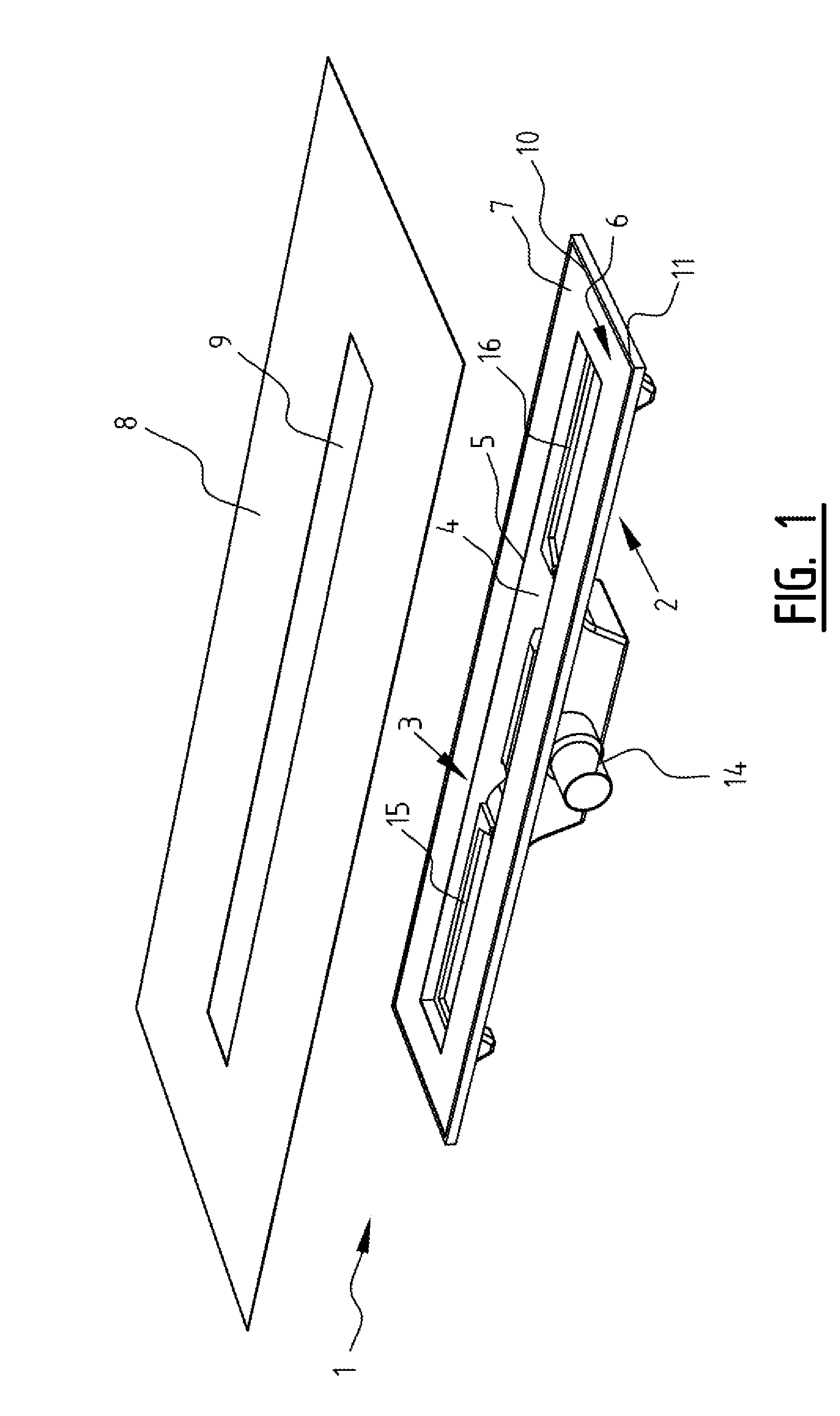

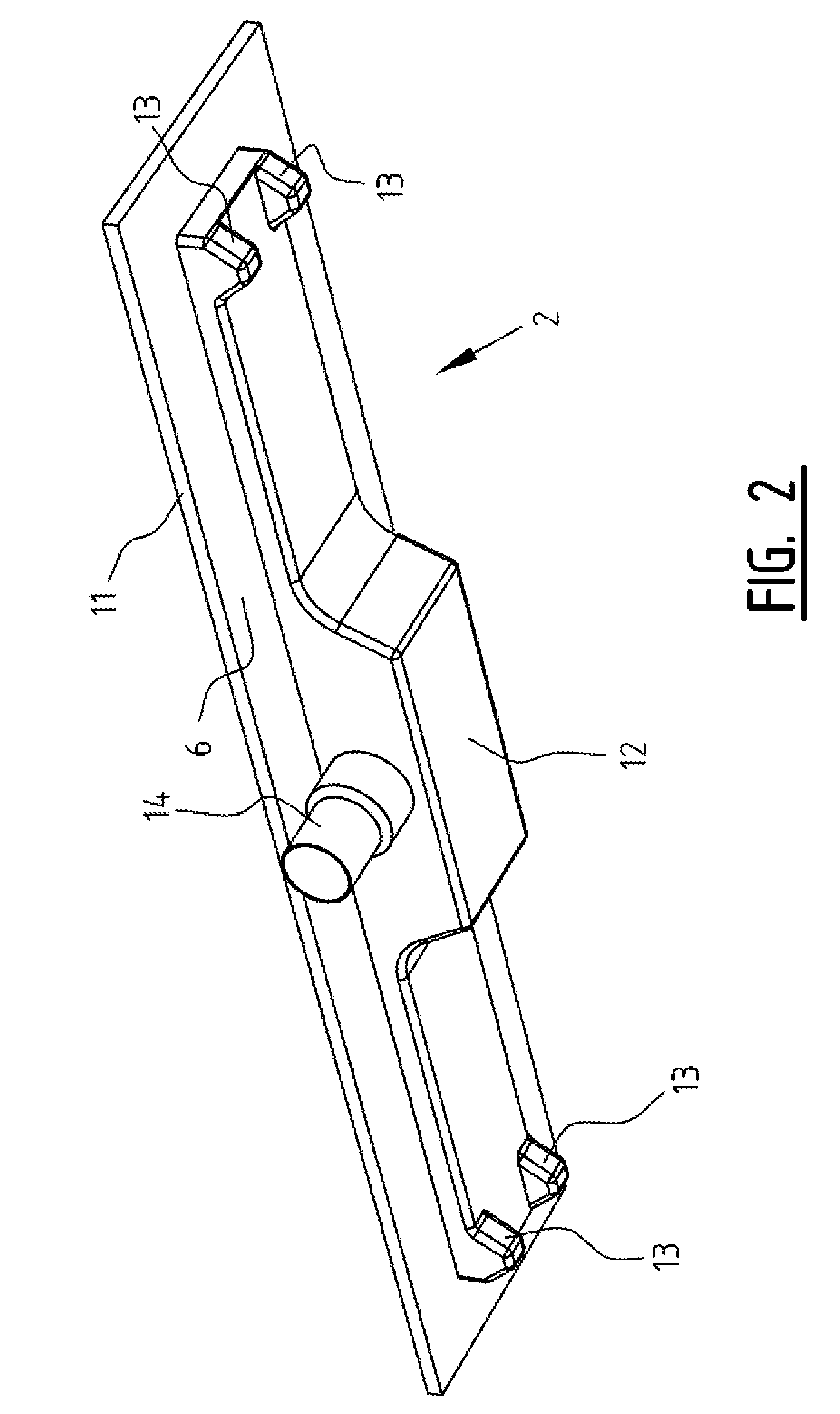

[0035]a drain assembly according to the invention will be illustrated hereinbelow with reference to FIGS. 1-5. The drain assembly comprises a drain body 1 with an upper side 3 and an underside 2. Drain body 1 is provided on its upper side 3 with an inlet zone 4 with a periphery 5. This periphery 5 transposes into a substantially horizontally extending peripheral flange 6. Underside 3 of drain body 1 is preferably intended to be arranged directly into a floor material such as mortar. The underside of peripheral flange 6 is thus placed directly against the floor material here, as will be further illustrated with reference to FIGS. 6A-D.

[0036]The drain body is preferably manufactured from a plastic which adheres to the typical floor materials such as mortar, and preferably from a mouldable plastic. It is however also possible to manufacture the drain body from metal. An example of a suitable material is a mouldable plastic on the basis of polyester resins and aluminium trihydrates. Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com