Thermodynamic cycle system for moving vehicle

a technology of moving vehicle and cycle system, which is applied in the direction of battery/fuel cell control arrangement, domestic cooling apparatus, lighting and heating apparatus, etc., can solve the problems of inability to lower the temperature of the cooling medium, the air conditioning system set up on the moving vehicle is not equipped, etc., to enhance the energy-saving effect of indoor air conditioning, enhance the adjustment function, and minimize the effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

1st embodiment

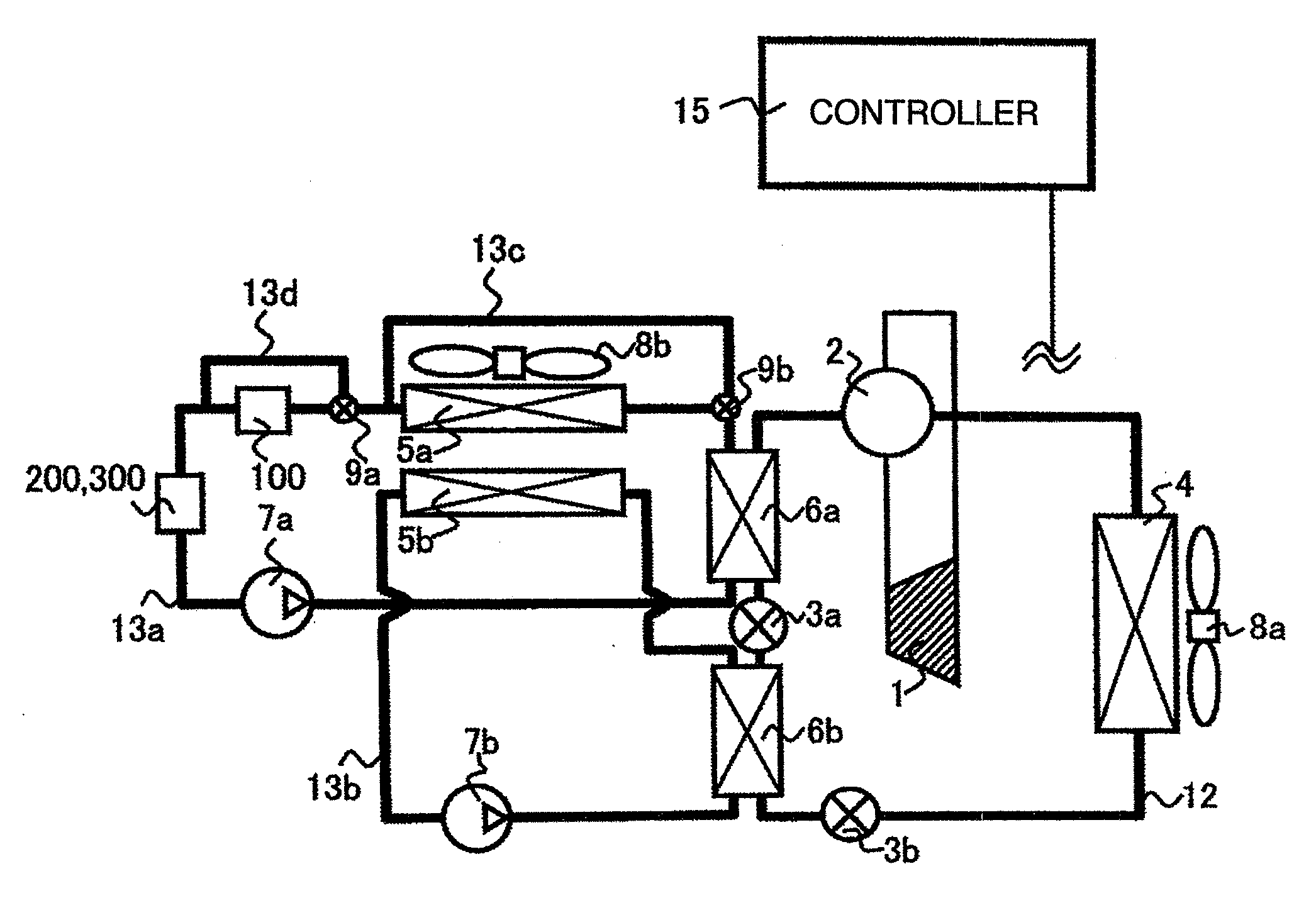

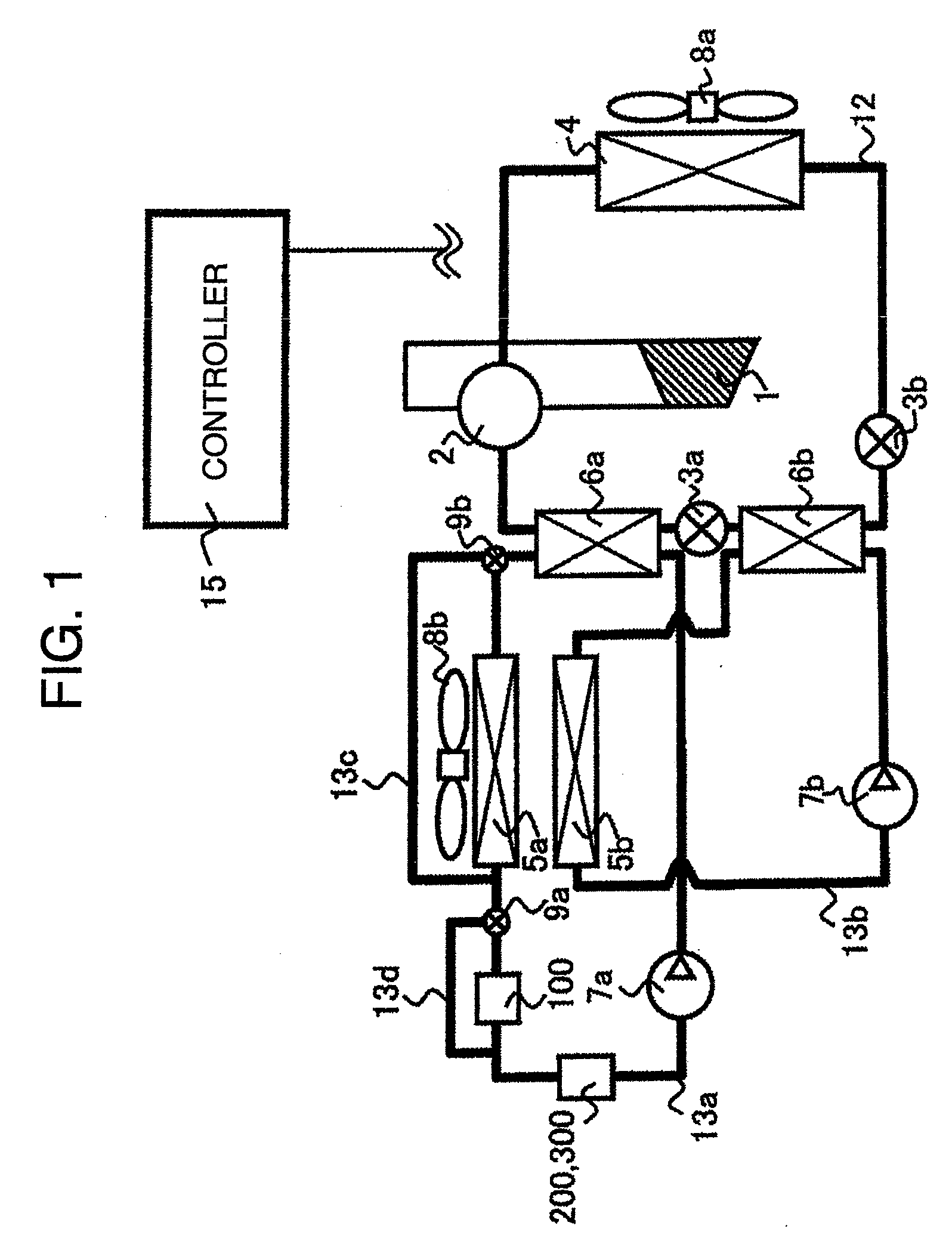

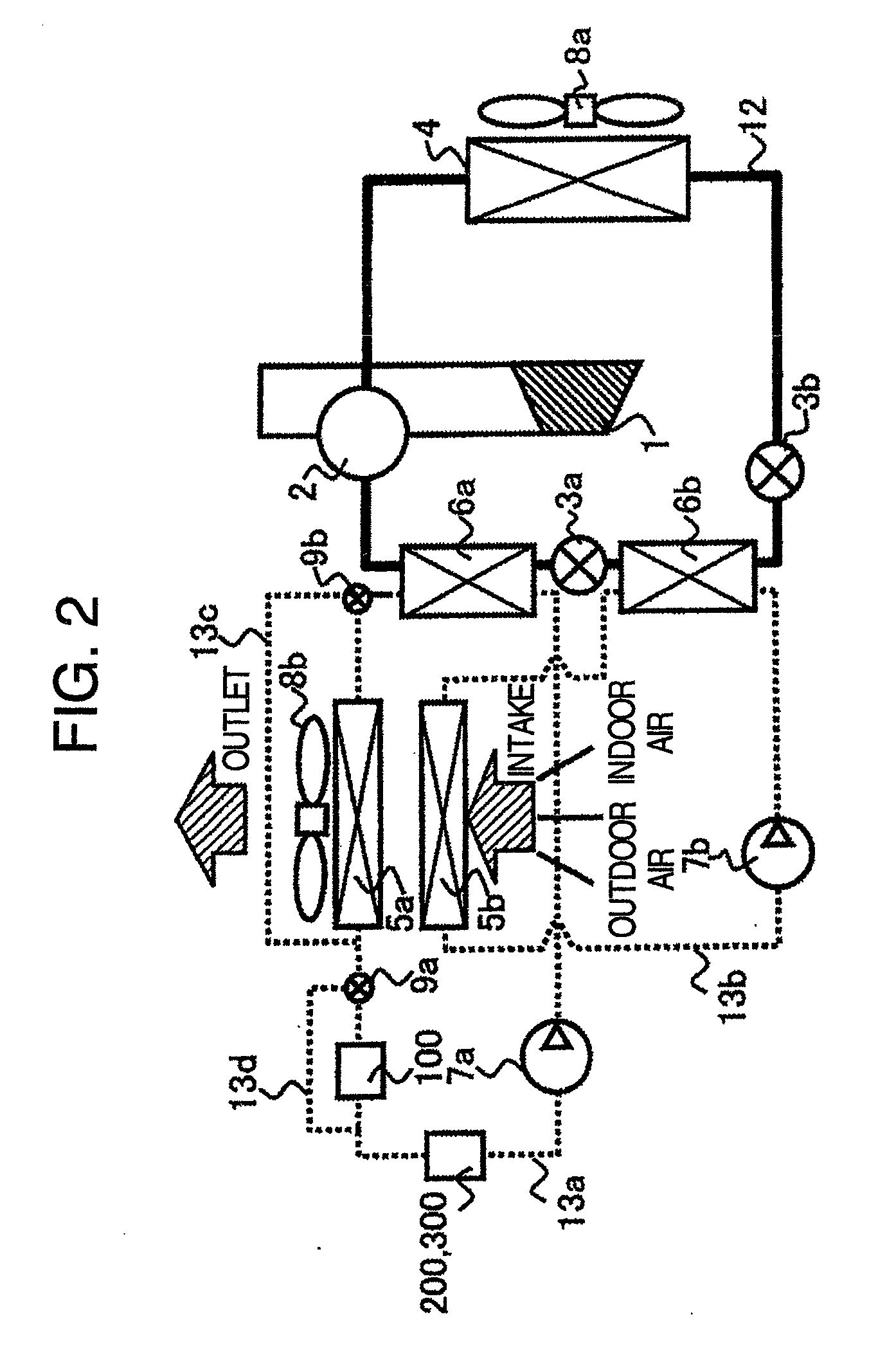

[0094]Referring to FIG. 1 through FIG. 8, the explanation will be given below regarding a first embodiment of the thermodynamic cycle system set up on the EV 1000.

[0095]FIG. 1 through FIG. 8 illustrate the configuration of the thermodynamic cycle system set up on the EV 1000.

[0096]Incidentally, FIG. 2 illustrates, with the solid line, a refrigerant pipe 12 (i.e., primary-side thermodynamic cycle circuit) through which a refrigerant such as HFC-134a flows. Also, FIG. 2 illustrates, with the dotted lines, heat-transferring medium pipes 13a and 13b (i.e., secondary-side thermodynamic cycle circuit) through which liquid-state cooling agents (i.e., heat-transferring media) such as water or antifreeze solution flow.

[0097]The thermodynamic cycle system set up on the EV 1000 includes a thermodynamic cycle circuit. As illustrated in FIG. 1 and FIG. 2, this thermodynamic cycle circuit is separated into the primary-side thermodynamic cycle circuit for performing heat exchange with an outdoor s...

2nd embodiment

[0143]Referring to FIG. 9 and FIG. 10, the explanation will be given below concerning a second embodiment of the thermodynamic cycle system set up on the EV 1000.

[0144]The present embodiment is a modified embodiment of the first embodiment. Concretely, the correspondence relationship between the intermediate heat exchangers 6a and 6b and the first and second heat-transferring systems is a relationship which is inversed to the one in the first embodiment. Namely, the cooling liquid in the first heat-transferring system and the refrigerant in the refrigeration cycle system are heat-exchanged with each other by the intermediate heat exchanger 6b which is deployed between the pressure reducers 3a and 3b. Also, the cooling liquid in the second heat-transferring system and the refrigerant in the refrigeration cycle system are heat-exchanged with each other by the intermediate heat exchanger 6a which is deployed between the pressure reducer 3a and the four-way valve 2.

[0145]The other confi...

3rd embodiment

[0148]Referring to FIG. 11, the explanation will be given below regarding a third embodiment of the thermodynamic cycle system set up on the EV 1000.

[0149]The present embodiment is an improved embodiment of the second embodiment. In the present embodiment, an outdoor heat exchanger 14 is provided on the bypass pipe 13c. The outdoor heat exchanger 14 is deployed in a side-by-side manner with the outdoor heat exchanger 4 such that the exchanger 14 is deployed on the upstream side of the outdoor heat exchanger 4 with reference to the flow of the air sent by the fan 8a. Based on this deployment, the outdoor heat exchanger 14 performs the heat exchange between the air sent by the fan 8a and the cooling liquid flowing through the bypass pipe 13c. Also, in the present embodiment, the three-way valve 9b is deployed between the pump 7a and the intermediate heat exchanger 6b. Thanks to this deployment of the valve 9b, it is made possible to cause the cooling liquid before being heat-exchanged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com