Hydrocarbon production system, method for performing clean-up and method for controlling flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

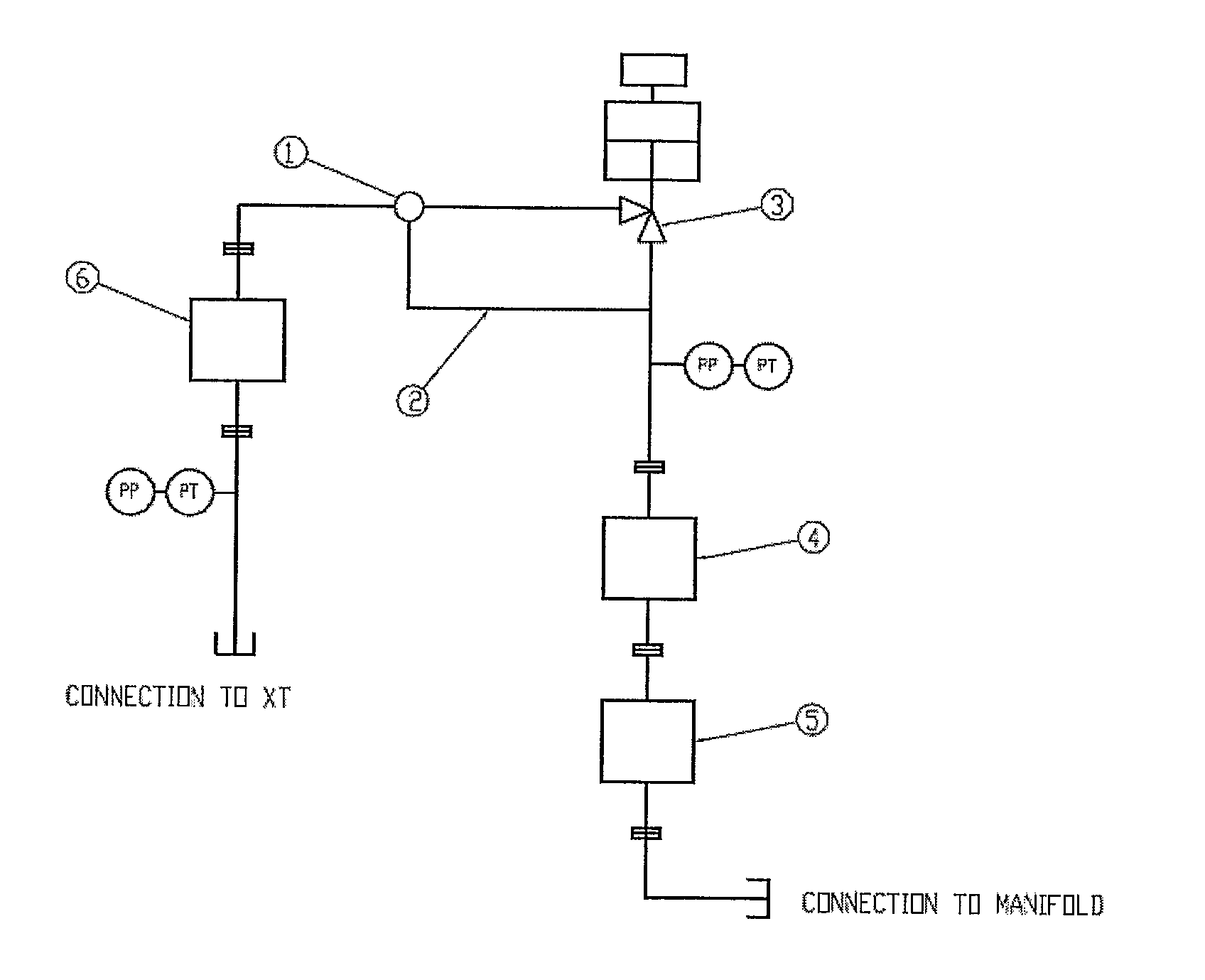

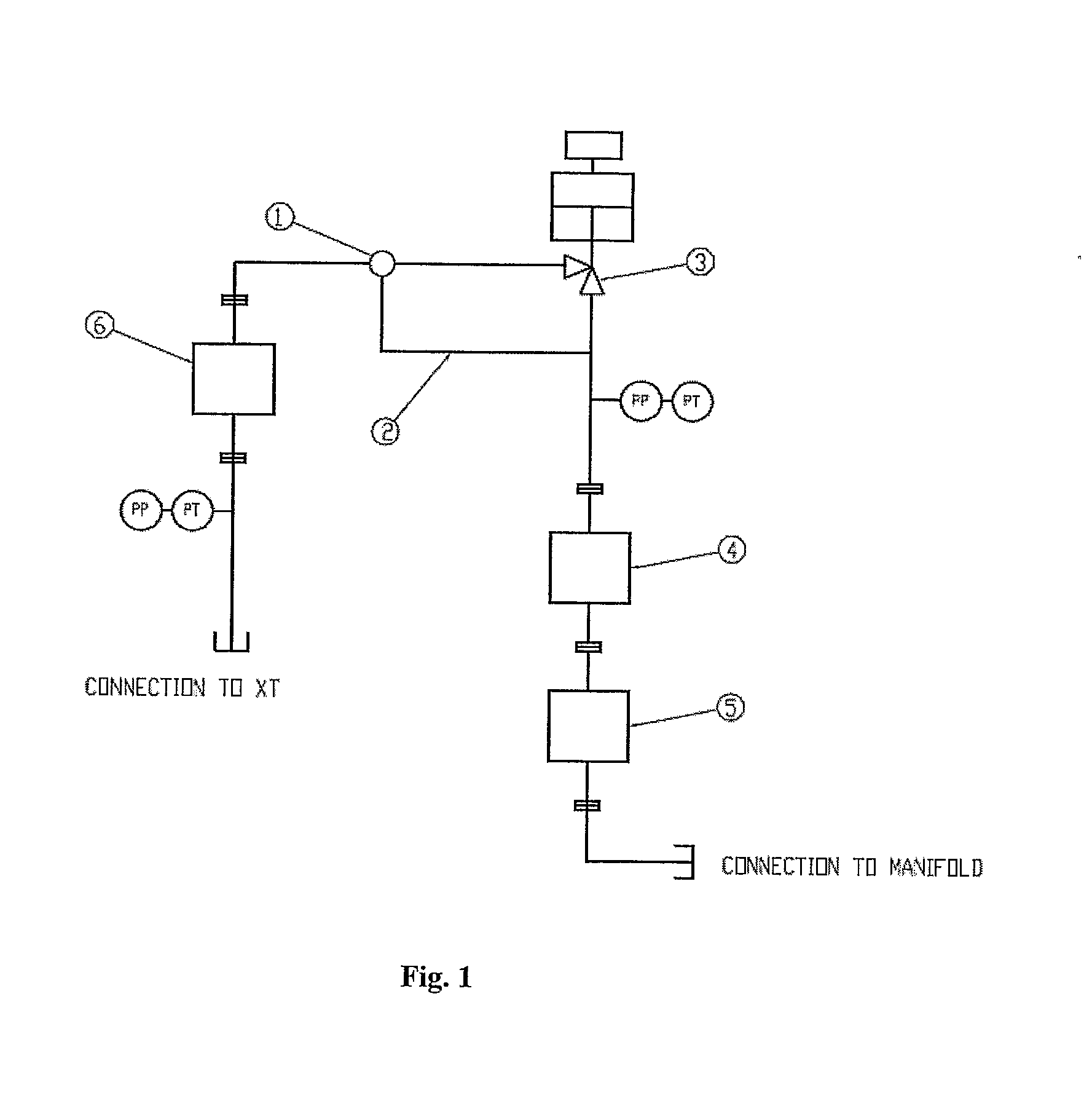

[0026]As seen in FIG. 1, a pipeline 7 has a connection to a Xmas Tree and a subsea well (commonly denoted by reference numeral 8) in one end, and the pipeline 7 is connected to a manifold 9 at the other end. A choke valve 3 for controlling the flow through the pipeline 7 is connected between the two end points 8, 9 of the line 7. For illustration purposes only, typical building blocks are also shown in FIG. 1. Such building blocks can be a flow meter 4, sand sensor 5 and injection line 6. Pressure and temperature sensors PP, PT are also inserted in the pipeline 7. In regular operation of the system seen in FIG. 1, fluid from the subsea well flows from the Xmas tree 8 through the choke valve 3 to the manifold 9. During a clean-up process of the subsea well or Xmas Tree 8 the choke valve 3 can not safely handle the debris in the fluid. Thus a bypass line 2 is implemented as an additional line 2, in parallel with the choke valve 3 to prevent the choke valve 3 from being damaged by debr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com