Actuators for gun-fired projectiles and mortars

a technology of actuators and projectiles, which is applied in the direction of machines/engines, explosions, lighting and heating apparatus, etc., can solve the problems of difficult or impractical implementation of occupying a considerable amount of weaponry internal volume, and their application to gun-fired projectiles and mortars will be very limited, so as to achieve high efficiency and cost-effectiveness, the effect of simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057]Although the present invention is applicable to numerous types of actuators, it is particularly useful in the environment of actuators for gun-fired projectiles and mortars. Therefore, without limiting the applicability of the present invention to actuators for gun-fired projectiles and mortars, it will be described in such environment.

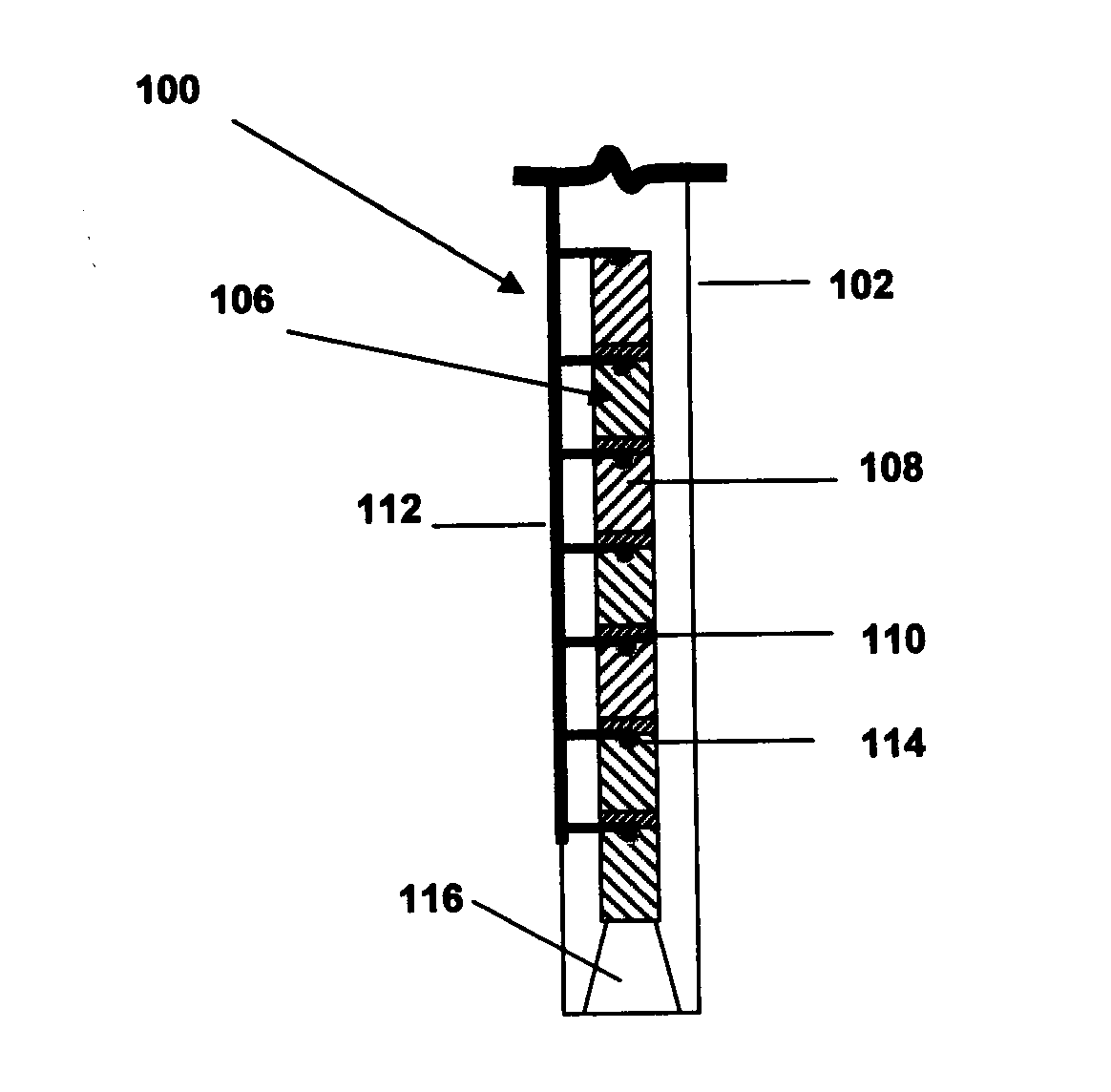

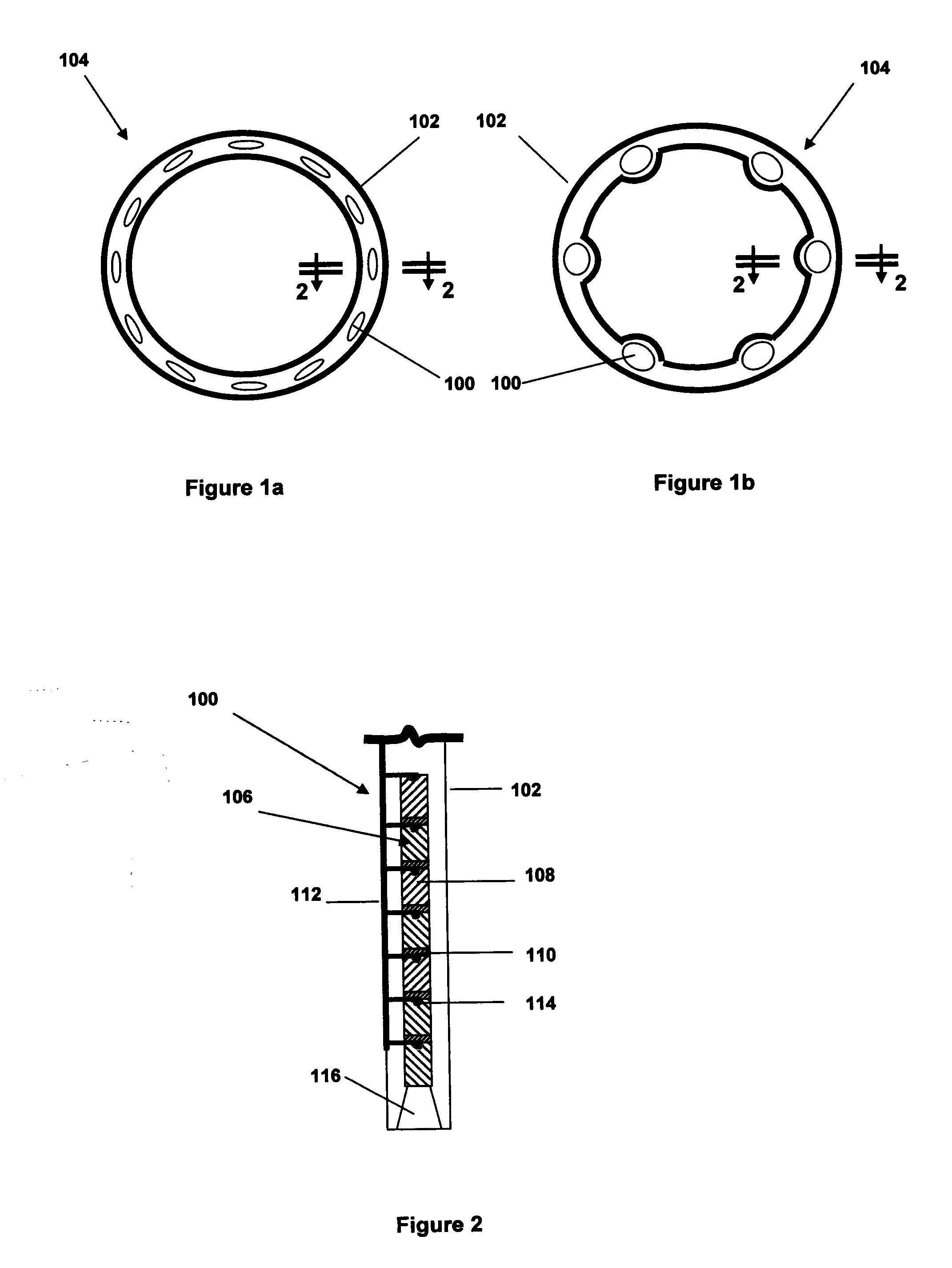

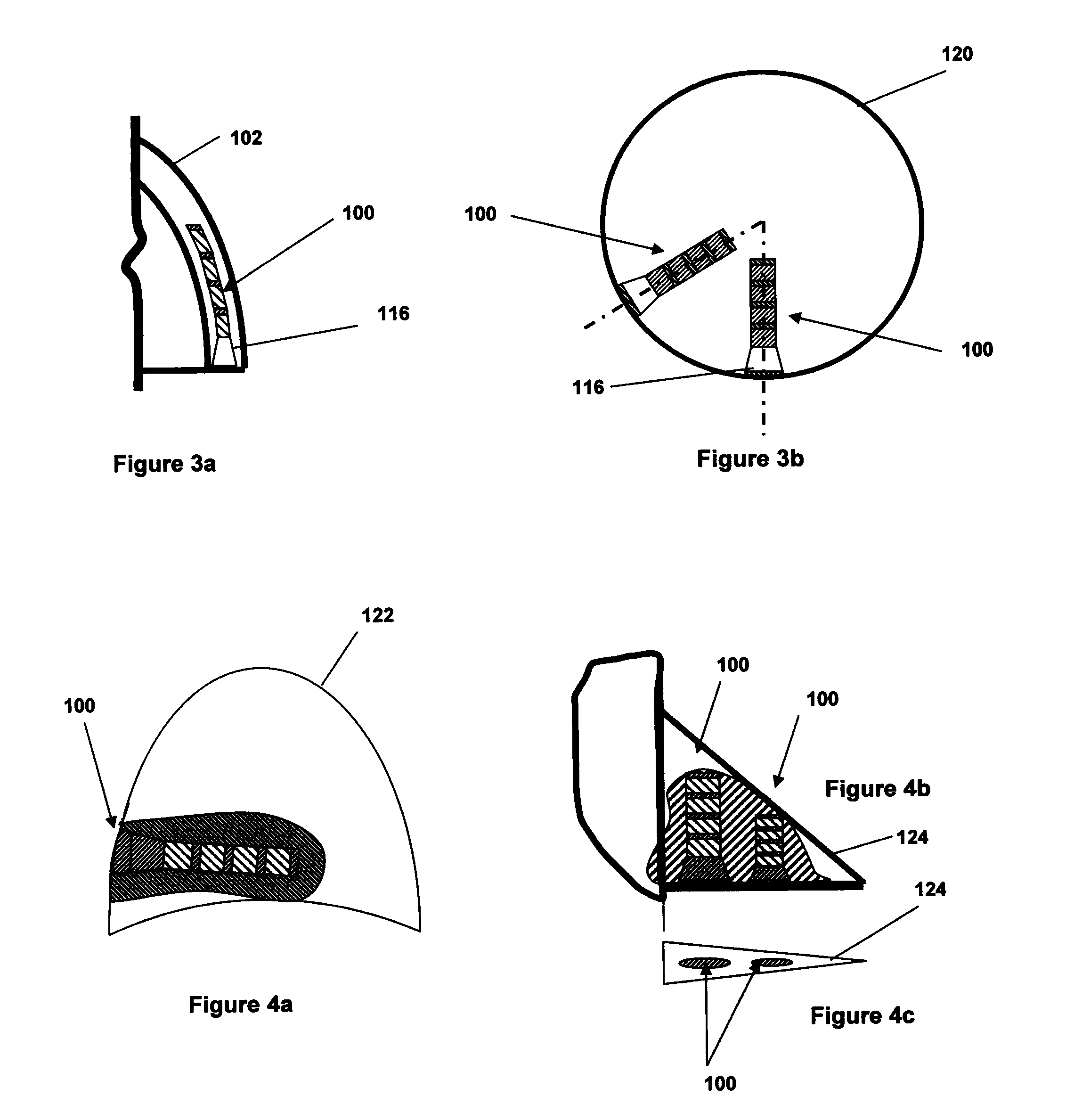

[0058]The disclosed actuators and method of their manufacture and integration into the structure of projectiles will now described in detail with regard to the Figures. It is shown that the disclosed actuators would provide very cost effective and have high actuation authority and dynamic response characteristics, while occupying very small useful projectile volume and requiring very low electrical power. It is also shown that the disclosed actuators can be capable of being readily scaled to the desired application. The disclosed actuator concepts could be built as modular units and could form the basis for developing a common actuator solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com