Burner with split combustion and exhaust induction air paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

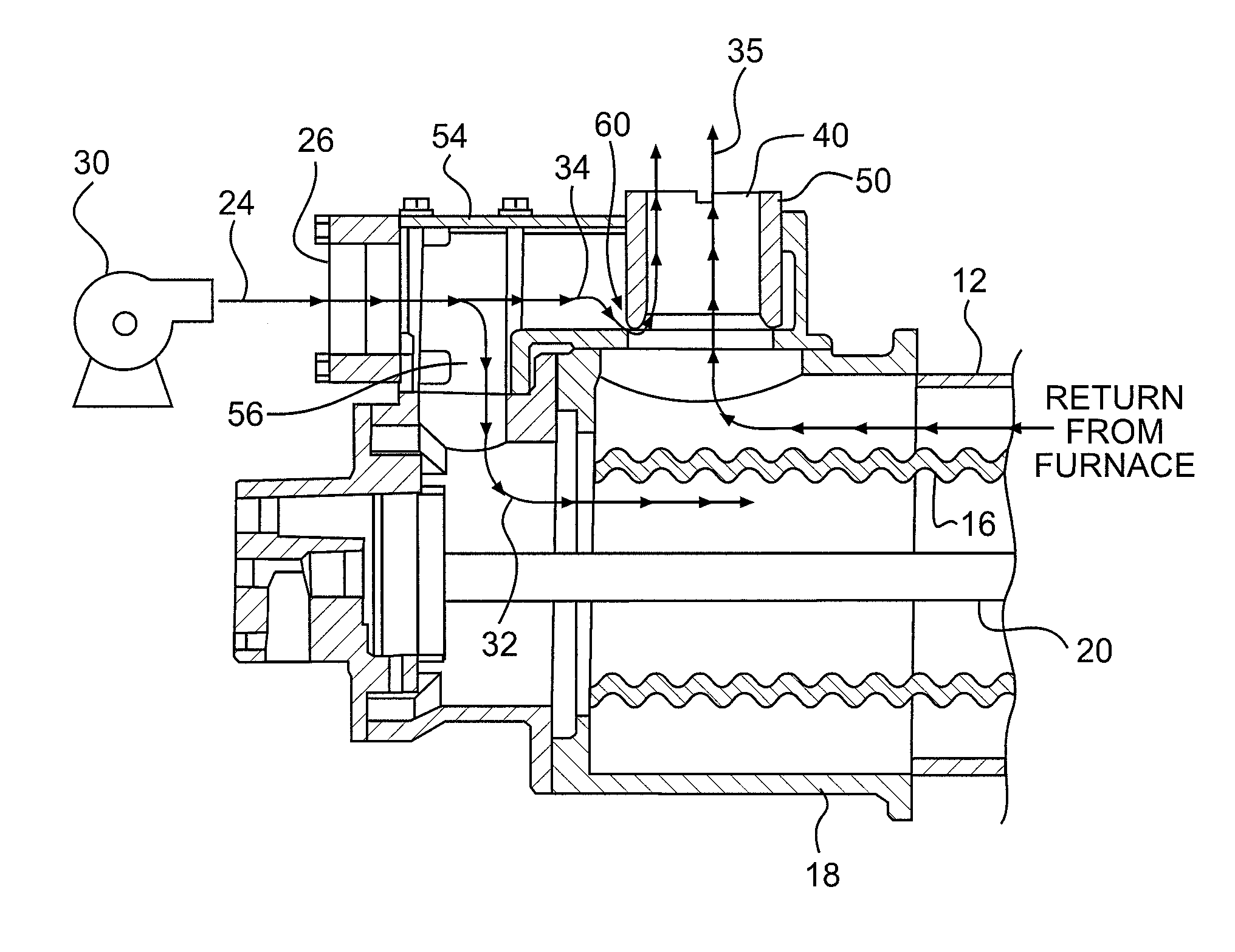

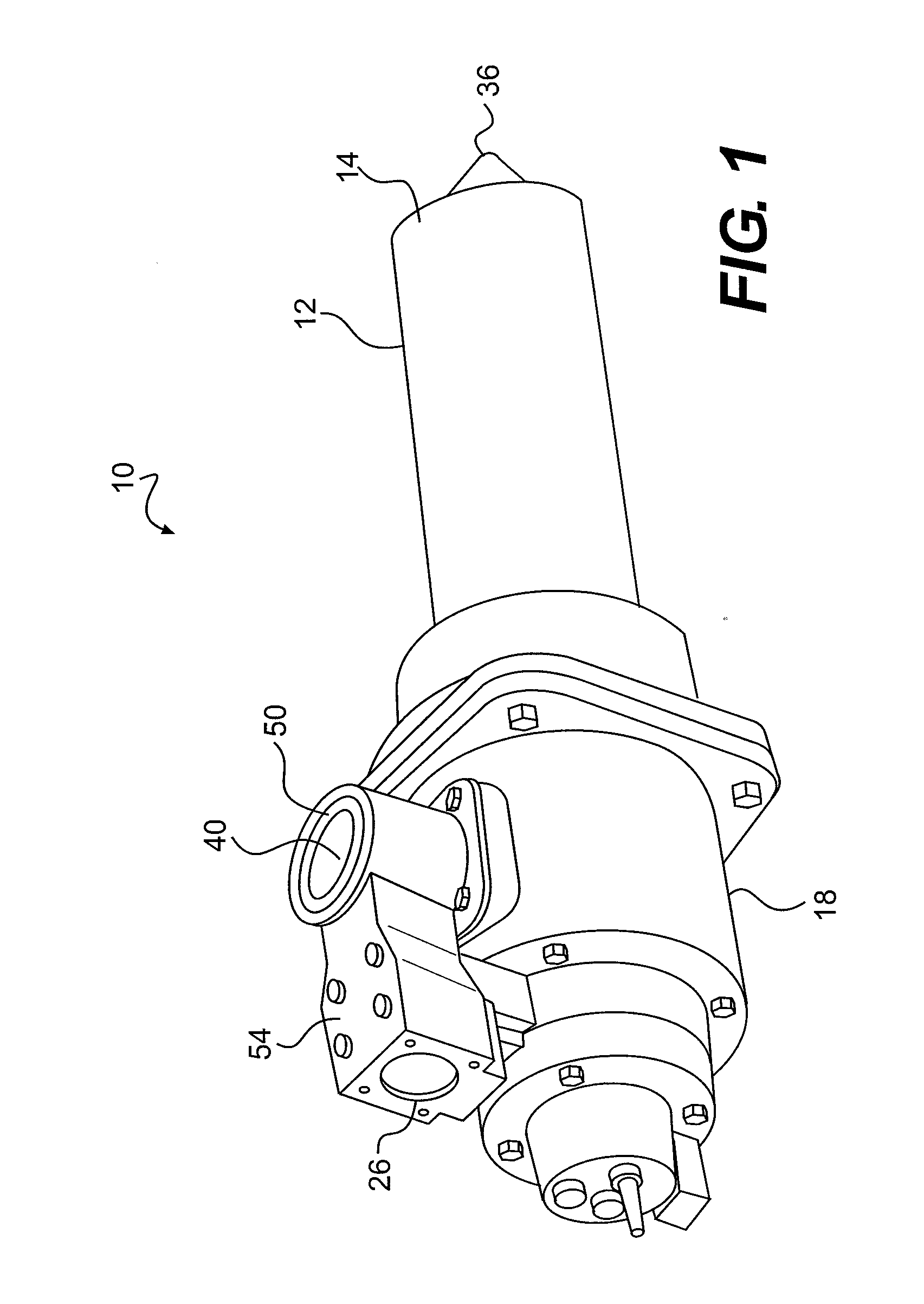

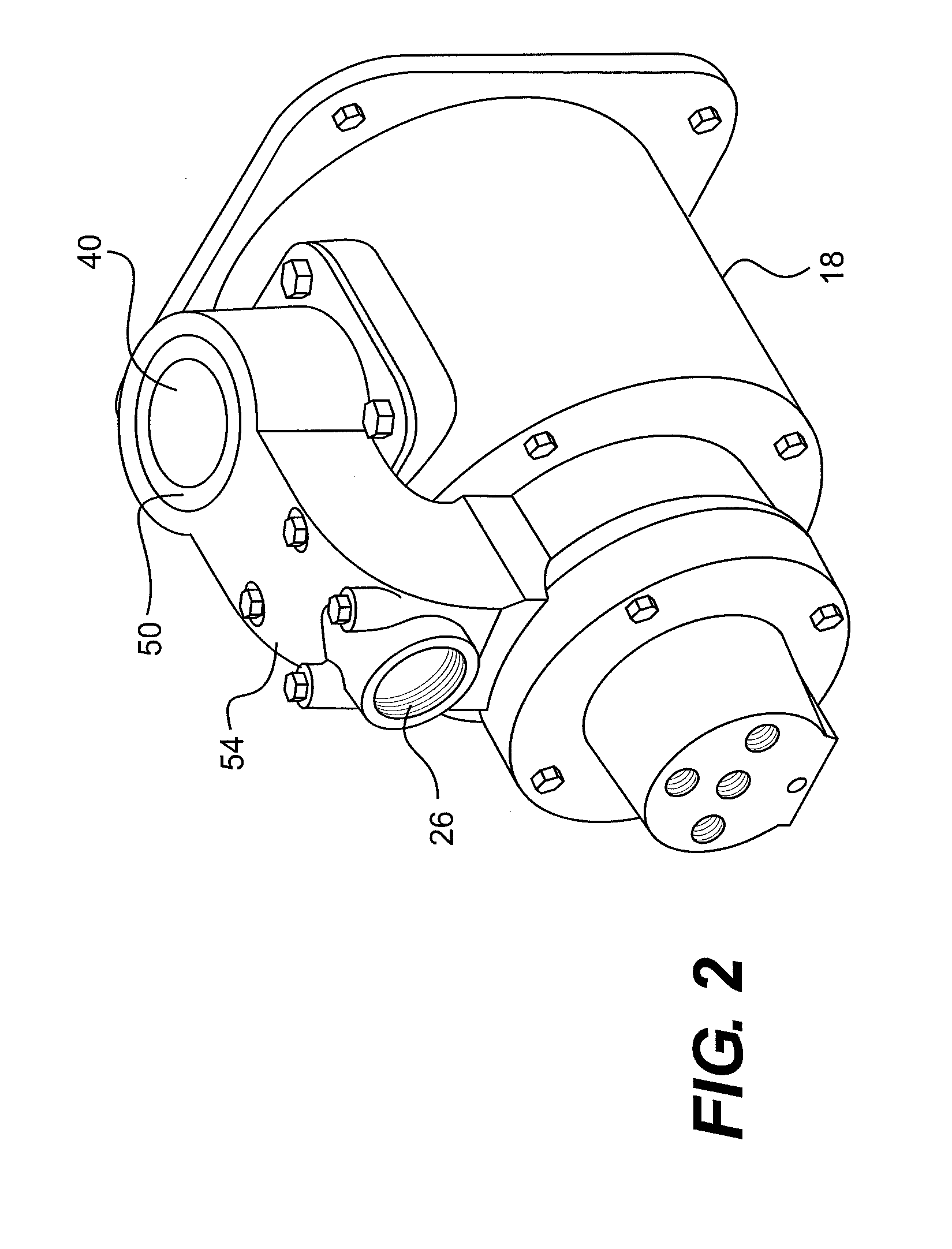

[0021]Reference will now be made to the drawings wherein like elements are designated by like reference numbers in the various views. FIG. 1 illustrates a burner 10 including a generally hollow tubular cover tube 12 having an open end 14 that projects into a furnace or other environment to be heated. As best seen in FIG. 3, the cover tube 12 is disposed in surrounding relation to a hollow, substantially cylindrical heat recuperator 16 of ceramic or the like having a convoluted surface extending outwardly from a housing 18. The recuperator 16 surrounds a fuel tube 20 feeding a burner head within a combustion chamber located adjacent to the open end 14.

[0022]As shown in FIG. 3, an air supply designated generally as 24 is introduced into an air inlet port 26 from a blower 30 or other suitable supply source. Within the housing 18, the air supply 24 is split into a combustion feed stream 32 and an exhaust induction stream 34. An eductor body 54 is attached to the housing 18. The air inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com