Synthetic Sports Turf Having Lowered Infill Levels

a synthetic turf and infill layer technology, applied in the field of synthetic sports fields, can solve the problems of high raw material cost of field installation, study of infill depth, etc., and achieve the effects of preventing graininess, and reducing the raw material cost of infill layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

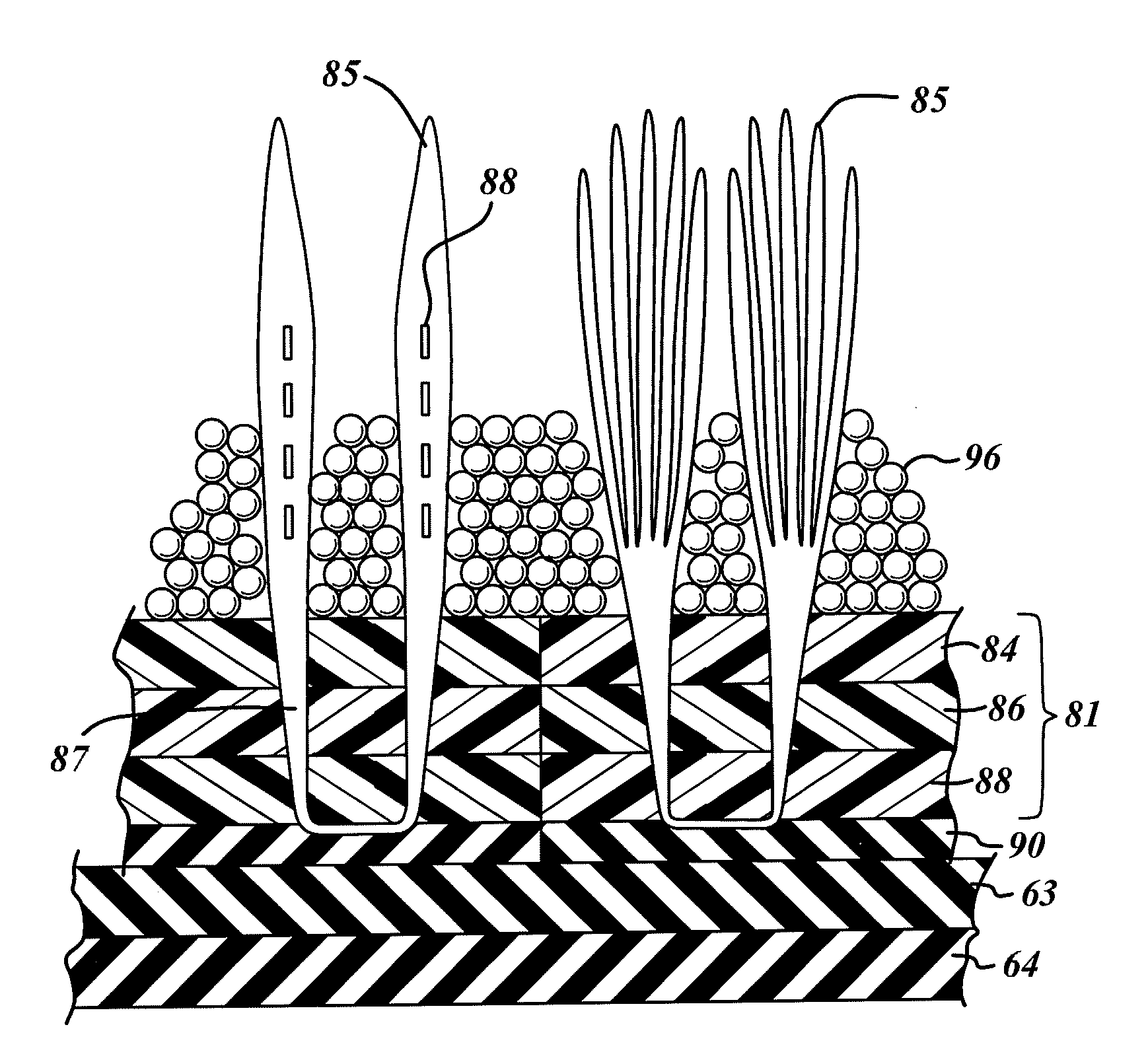

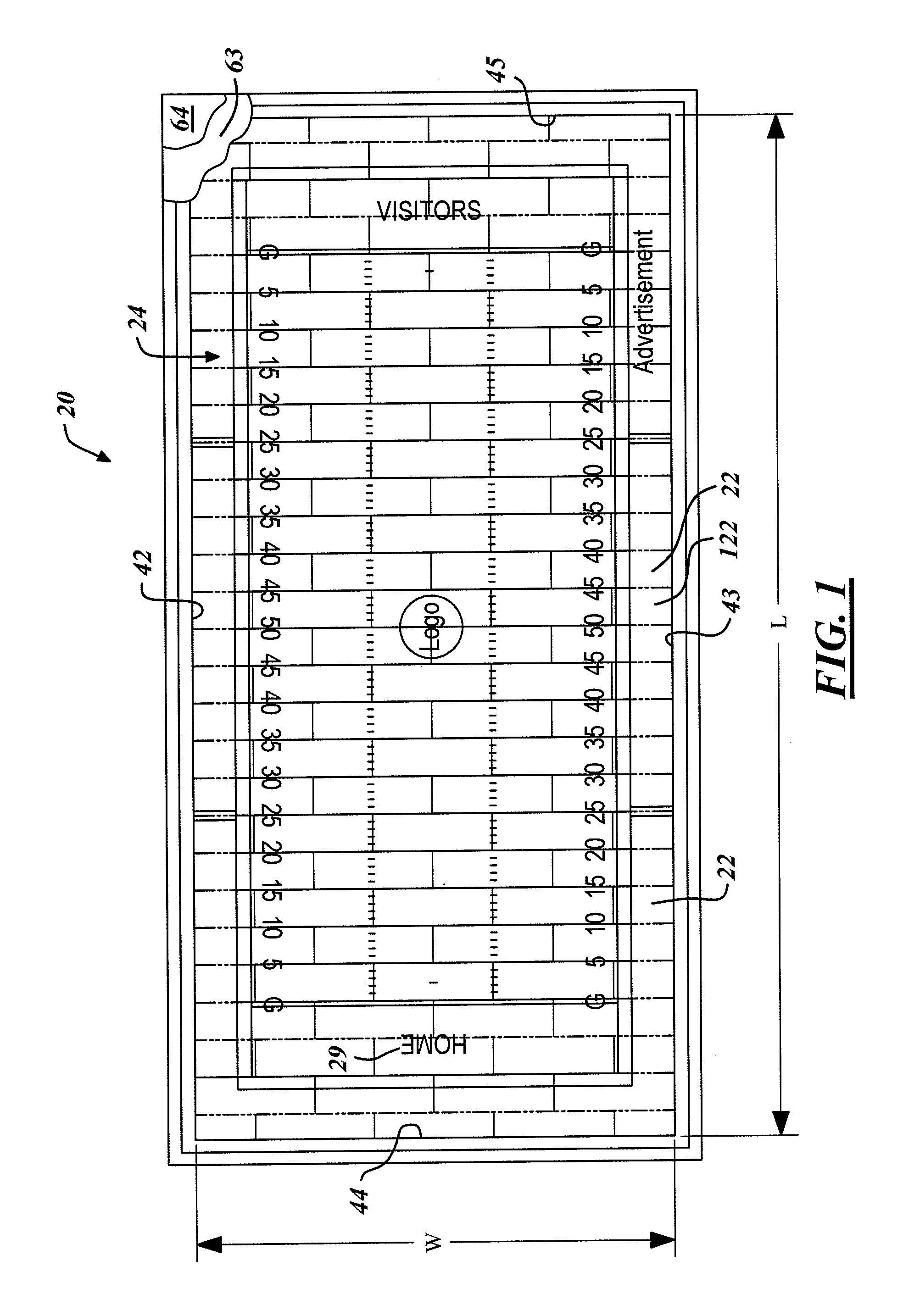

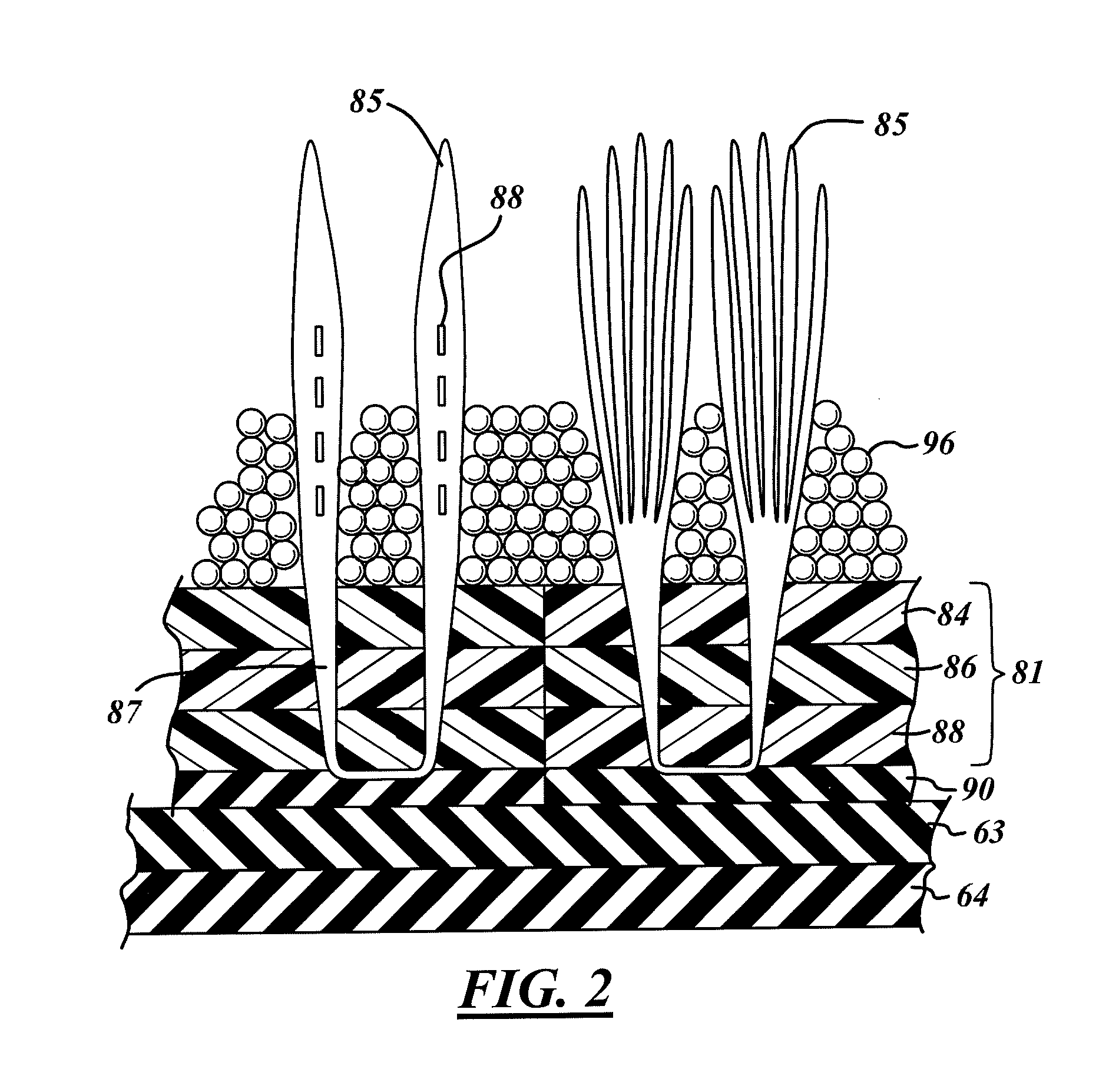

[0015]FIGS. 1 and 2 illustrate a top and side section views of a sports playing surface 20, here a football field, according to one preferred embodiment of the present invention. The playing surface 20 is formed having one or more strips 22 of a synthetic turf grass surface 24 on either side of a central strip 122. The strips 22, 122 are placed on top of a substrate 64 in rows across the field such that the respective edges 22A of adjacent strips 22 are substantially lined up and a cover the substrate 64 along a boundary defined by a first lengthwise side 44, a second lengthwise side 45, a first widthwise end 43 and a second widthwise end 44. Of course the boundary is defined by the ultimate end use and is not limited by the particular configuration described herein. it will be understood that the playing surface 20 can take on a variety of different configurations and the number, length, and shape of the strips can vary. Additionally, the playing surface 20 can be utilized for a va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com