Bus bar for secondary battery and secondary battery module

a secondary battery and bus bar technology, applied in the direction of current conducting connection, cell component details, cell components, etc., can solve the problem of damage to the stick portion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0053]Hereinafter, the present invention will be described with reference to the attached drawings.

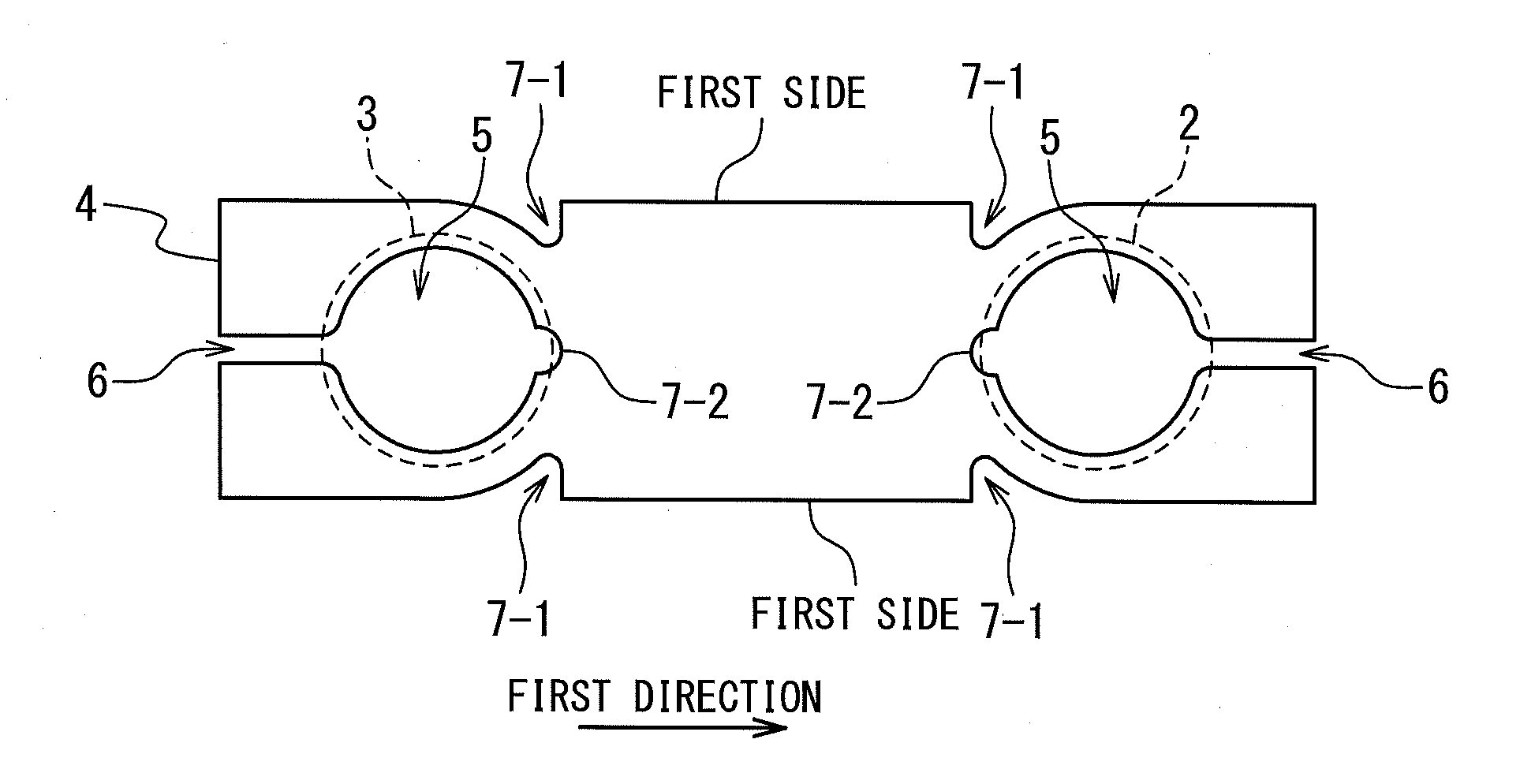

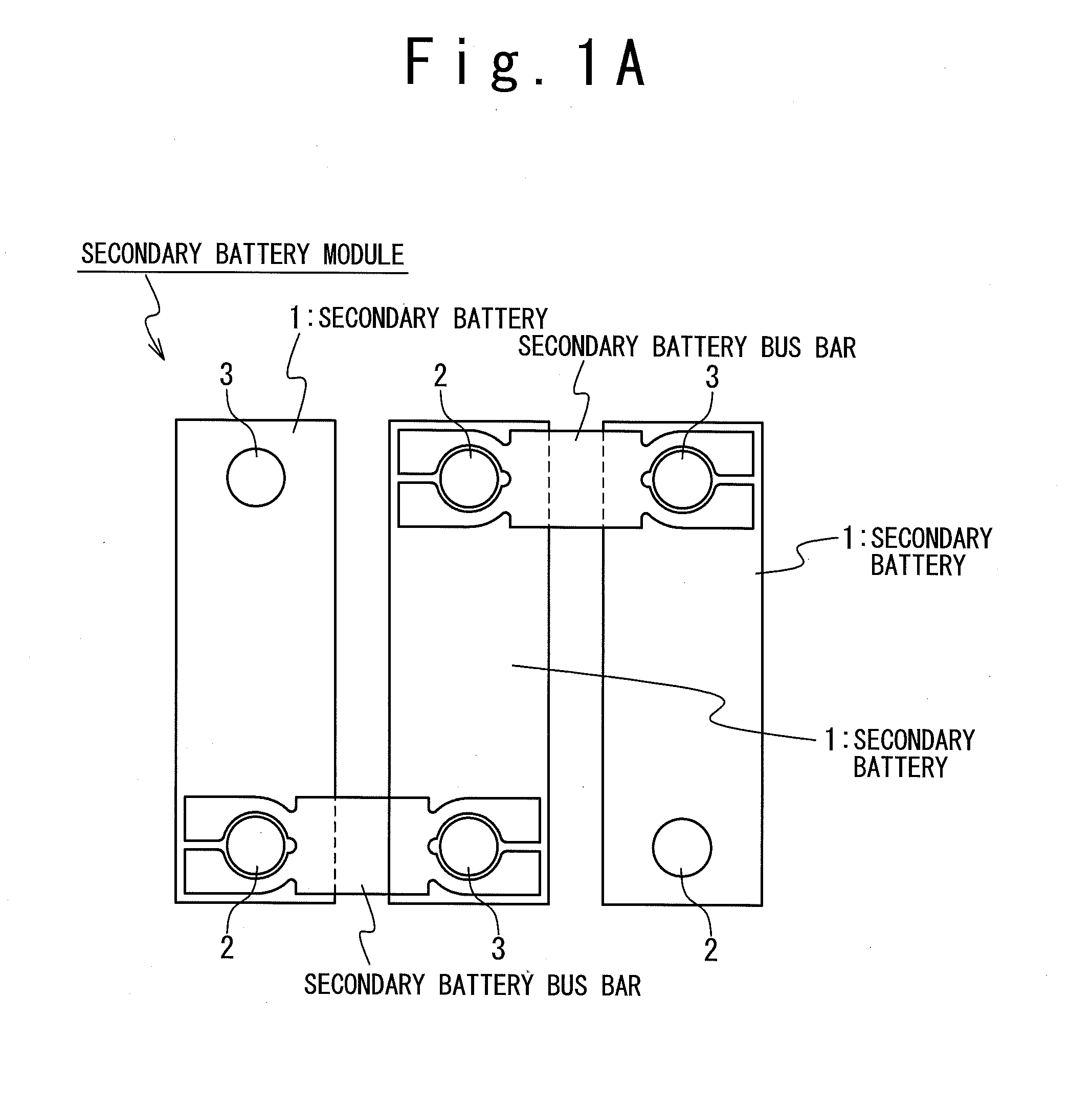

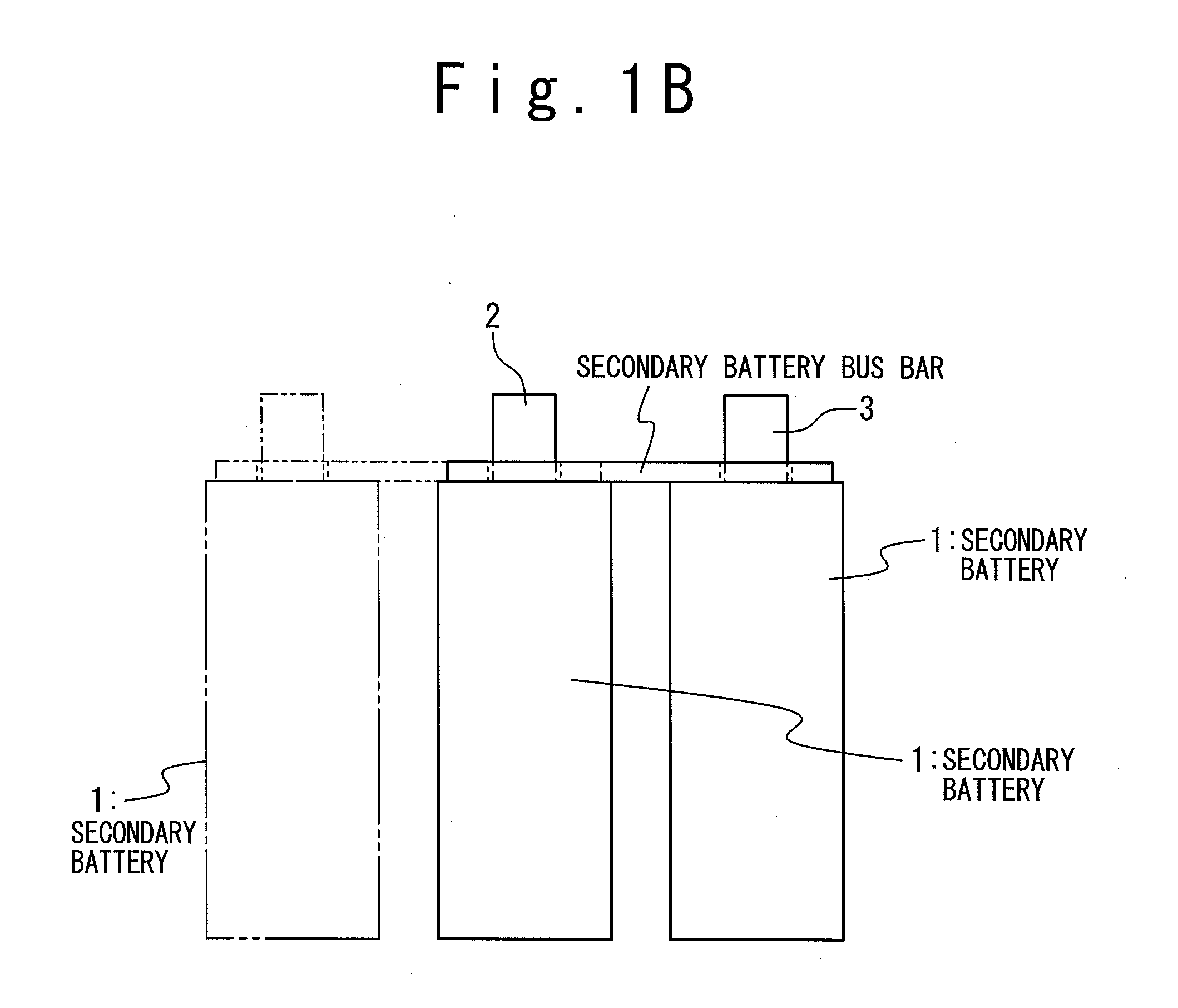

[0054]FIG. 1A is a top view of a secondary battery module according to a first embodiment of the present invention. Also, FIG. 1B is a side view showing the secondary battery module.

[0055]As shown in FIG. 1A and FIG. 1B, the secondary battery module according to the present embodiment is provided with a plurality of secondary batteries 1. Adjacent two of the plurality of secondary batteries 1 are electrically connected by a bus bar for the secondary battery (hereinafter, to be referred to as a bus bar).

[0056]Each of the plurality of secondary batteries 1 has a cell container. An electricity generating element (not shown) which is chargeable and dischargeable is accommodated in the cell container. The electricity generating element is provided with a positive electrode and a negative electrode. Non-aqueous electrolyte is filled in the cell container and the electricity generating elemen...

second embodiment

[0083]Next, the second embodiment of the present invention will be described. FIG. 14 is a top view showing the bus bar according to the present embodiment. In the present embodiment, it is different from the first embodiment in the point that notches 9 for the auxiliary bar 10 are provided for end portions of the plate section 4 and in the point that the auxiliary bar 10 is provided for the notches 9. Because the other points may be same as in the first embodiment, the detailed description is omitted.

[0084]The two notches 9 are provided on both ends of the plate section 4 in the first direction. The two notches 9 are provided to put the first slit section 6 between them in a direction orthogonal to the first direction (a second direction in FIG. 14). These notches 9 are provided to attach the auxiliary bar 10 to the plate section 4.

[0085]The auxiliary bar 10 is provided to auxiliarily fasten the electrode terminal 2 or 3 in the opening section 5. FIG. 15 is a side cross sectional v...

third embodiment

[0087]Next, a third embodiment of the present invention will be described. In the present embodiment, a cover with a large elastic modulus is added. Because the other points may be same as those of the above-mentioned embodiments, the detailed description is omitted.

[0088]FIG. 16 is a perspective view showing the bus bar according to the present embodiment. The bus bar is provided with a cover 11 in addition to the plate section 4. The cover 11 is provided with a flat portion 11-1, opening sections 11-2 and side sections 11-3. The flat portion 11-1 is a portion which covers the surface of the plate section 4. The side sections 11-3 are portions which cover the side surfaces of the plate section 4. The opening sections 11-2 are portions through which the electrode terminals 2 or 3 pass.

[0089]For example, the cover 11 is formed of material with larger elastic modulus than that of the plate sections 4 such as rubber.

[0090]In the third embodiment, the plate section 4 is covered by the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| stress | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com